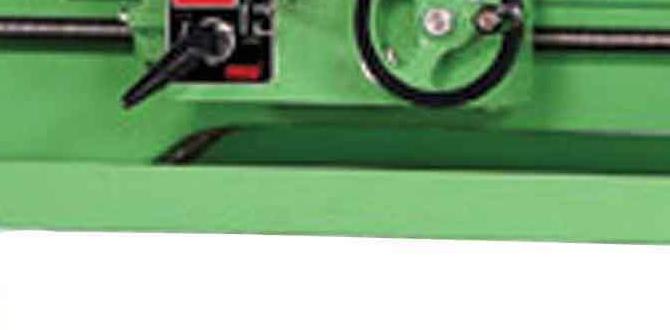

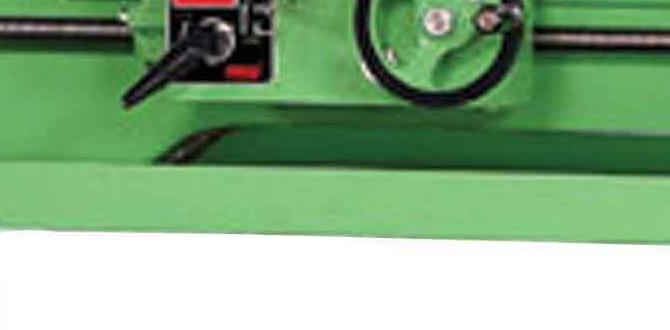

Have you ever wondered how a metal lathe works? This machine can create amazing items! But what happens when parts start to wear out? It can be frustrating, right? Let’s take a closer look at one important part: the metal lathe chuck key.

The chuck key is a small tool, yet it plays a big role. It helps hold the workpiece tightly in place. Without it, your projects could go from impressive to messy in no time. Imagine your art piece suddenly wobbling while you work!

Now, think about rebuilding a lathe. This might sound complicated, but it can be fun! Many hobbyists have turned old lathes into fantastic machines again. They replace parts like the chuck key and discover new skills along the way. Did you know that rebuilding a lathe can save money too?

Let’s explore why rebuilding a lathe is worth your effort. Join us on this journey to understand the importance of the metal lathe chuck key. You might just find out how it can inspire your next project!

Lathe Rebuilding: Essential Metal Lathe Chuck Key Guide

Lathe Rebuilding: Metal Lathe Chuck Key

Rebuilding a metal lathe can breathe new life into your workshop. A crucial part of this process is the metal lathe chuck key. This small tool plays a big role. It helps you tighten or loosen the chuck, securing your workpiece. Imagine trying to work without it! Did you know that a well-maintained chuck key can improve your lathe’s accuracy? Keeping it in good shape ensures that your projects turn out great every time. So, as you rebuild your lathe, don’t overlook the importance of the chuck key!What is a Lathe Chuck Key?

Definition and purpose of a chuck key. Types of lathe chuck keys available.A lathe chuck key is a handy tool used to tighten or loosen the chuck on a lathe machine. You can think of it as the “key” to your lathe party! Its main job is to hold your workpiece securely, preventing it from doing the tango while you’re working. There are several types of lathe chuck keys available, including hex keys, ratchet keys, and T-handles. Each has its own unique way of making the job easier and keeping your fingers safe.

| Type of Chuck Key | Purpose |

|---|---|

| Hex Key | Simple and effective for basic chucks. |

| Ratchet Key | Quick adjustments without losing grip. |

| T-handle Key | Extra leverage for stubborn chucks. |

Importance of a Working Chuck Key in Lathe Rebuilding

Role of a chuck key in precision work. Risks and issues caused by a malfunctioning chuck key.A working chuck key is like a best friend to your lathe. It secures your workpiece tightly for precision work. Without it, tools can slip, which may turn your project into a messy disaster. Picture this: your piece wanders off like a misbehaving puppy! A malfunctioning chuck key can lead to cutting inaccuracies and even accidents. Do you want flying parts? I don’t think so! So, keep that chuck key in tip-top shape!

| Chuck Key Functions | Issues with Broken Chuck Keys |

|---|---|

| Secures workpieces | Increased risk of accidents |

| Ensures precision cutting | Damage to projects |

| Facilitates smooth operation | Possible equipment damage |

Steps to Rebuild a Metal Lathe

Essential tools and materials required. Detailed procedure for rebuilding.Rebuilding a metal lathe can be exciting and rewarding. To start, gather essential tools and materials. Here’s what you need:

- Wrenches and screwdrivers

- Measuring tools (caliper, ruler)

- Replacement parts

- Lubricants and grease

- Safety gear (gloves and goggles)

The rebuilding procedure includes several steps:

- Disassemble the lathe carefully.

- Inspect for wear or damage.

- Replace any broken parts.

- Clean all components.

- Reassemble and lubricate the lathe.

Following these steps will help you rebuild your lathe properly.

What tools do I need to rebuild a metal lathe?

You need basic hand tools like wrenches, screwdrivers, and measuring tools. Don’t forget safety gear like gloves and goggles. These items make rebuilding easier and safer.

Choosing the Right Chuck Key for Your Lathe

Factors to consider (size, compatibility, type). Common brands and recommendations.Choosing the right chuck key for your lathe is important. Think about these factors:

- Size: Ensure the chuck key fits your lathe snugly.

- Compatibility: Check if it matches your lathe’s brand.

- Type: Select between standard or special keys based on your tasks.

Common brands include Jacob’s and Craftex. They offer reliable options for most lathes. Reading reviews can help you find the best fit.

What should I consider when choosing a chuck key?

Consider size, compatibility, and type for the best fit. Always check for the right dimensions for your lathe.

Here are some tips:

- Verify the size before purchase.

- Look for trusted brands.

- Read user reviews for insights.

Common Problems with Chuck Keys and Solutions

Identification of wear and tear issues. Repair techniques and replacement options.Chuck keys can wear down over time. Look for signs like rust or rough edges. If you spot these issues, don’t worry! You have options. Here are some solutions:

- Replace the chuck key if it’s too worn.

- Clean it to remove any rust.

- Lubricate moving parts to keep them working smoothly.

Regular checks can help keep your lathe running well. A good key makes tasks much easier.

What are the signs of a damaged chuck key?

Common signs include visible rust and uneven wear. These problems can affect the tool’s performance.

When should you replace a chuck key?

Replace a chuck key when the teeth are worn or damaged. If it does not grip well, it’s time for a new one.

Maintenance Tips for Longevity of Chuck Keys

Recommended cleaning and storage practices. Frequency of inspection and replacement.To keep your chuck keys happy and working well, cleaning is essential. Wipe them down with a soft cloth after each use. Regularly check for rust or damage—think of it as a quick health check-up for your tools. It’s best to replace them every year or when they show signs of wear. Storing them in a designated toolbox keeps them safe. Remember, a well-cared chuck key is a friend for life, unlike that one sock that always goes missing!

| Practice | Frequency |

|---|---|

| Cleaning | After each use |

| Inspection | Monthly |

| Replacement | Annually or as needed |

FAQs About Lathe Rebuilding and Chuck Keys

Addressing common queries and misconceptions. Tips for troubleshooting common issues.Many folks have questions about lathe rebuilding and managing chuck keys. One common myth is that it’s too hard to fix a chuck key. But fear not! Most issues are pretty simple. If you’re struggling to tighten a chuck, it’s often due to dirt or wear. Just clean it up and check for parts that need replacing. When in doubt, read the manual; it’s like a treasure map but with less gold! Below is a helpful table of frequently asked questions for quick fixes:

| Question | Answer |

|---|---|

| What is a chuck key? | A tool used to tighten and loosen the chuck on a lathe. |

| Why does my chuck key slip? | It might be worn out or dirty. Clean and check it! |

| Can I rebuild my lathe on my own? | Yes! With some patience and elbow grease, you can! |

Expert Tips for Advanced Lathe Users

Techniques for optimizing lathe performance. Enhancements and upgrades for improved efficiency.Want to make your lathe purr like a kitten? First, focus on precision and speed. Adjust the spindle speed for different materials. It’s like changing gears in a race car—go fast when you can! Second, think about upgrading tools for better cuts. Quality tools can make all the difference. Adding a powerful motor can also speed things up. Remember, a happy lathe means smooth work and fewer headaches!

| Enhancements | Benefits |

|---|---|

| Quality Tooling | Better precision and smooth surfaces |

| Upgraded Motor | Increased efficiency and speed |

| Regular Maintenance | Extended lifespan and performance |

Conclusion

In summary, rebuilding a metal lathe chuck key can enhance your machinery’s performance. You should check for wear, clean parts, and replace what’s necessary. This maintenance can prolong your lathe’s life and improve your work quality. If you want to learn more, explore guides and videos online for hands-on tips and tricks. Happy rebuilding!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Rebuilding, Specifically Focusing On Metal Lathe Chuck Keys:Sure! Here are five questions about lathe rebuilding and chuck keys: 1. What is a chuck key? A chuck key is a tool that helps us tighten or loosen the parts of a lathe. 2. How do we use a chuck key? We insert the chuck key into the chuck and turn it to hold or release the material. 3. Why do we need a chuck key? We need a chuck key to keep things secure while the lathe spins. 4. What can happen if we lose a chuck key? If we lose a chuck key, we might not be able to change materials safely. 5. Can we make a new chuck key? Yes, we can make a new chuck key if we have the right materials and tools.

Sure! Please provide the question you would like me to answer.

What Are The Common Signs That A Metal Lathe Chuck Key Needs To Be Replaced Or Rebuilt?You should look for a few signs that your metal lathe chuck key needs help. First, if it feels loose or wobbly, it’s a problem. Second, check for any cracks or chips on the key. If the handle is hard to turn, it might be wearing out. Finally, if it doesn’t hold the tools tightly anymore, you need to replace it.

How Can I Determine The Correct Size And Type Of Chuck Key For My Specific Metal Lathe Model?To find the right size and type of chuck key for your metal lathe, first check your lathe’s manual. It usually has details about the chuck key you need. You can measure the chuck to see if it is big or small. If you’re still not sure, ask someone at a tool store for help. They can help you find the right one!

What Steps Should I Follow To Properly Rebuild And Maintain A Chuck Key For Optimal Performance On My Metal Lathe?To rebuild and maintain a chuck key for your metal lathe, first, clean it with a cloth. Check for any broken parts or rust. If you find any, replace them with new pieces. Always keep the chuck key lubricated with a small amount of oil. Finally, store it in a safe place when not in use.

Are There Any Safety Precautions I Should Consider When Working With The Chuck Key On A Metal Lathe?When using the chuck key on a metal lathe, always be cautious. Make sure the lathe is turned off before you start. Keep your hands away from the moving parts. Never leave the chuck key in the chuck, as it can fly out and hurt someone. Always wear safety glasses to protect your eyes.

What Materials Are Recommended For Constructing Or Restoring A Durable Chuck Key For Heavy-Duty Metal Lathe Use?For making a strong chuck key for a metal lathe, you should use good metals like steel. Steel can handle heavy use without breaking. You might also want to use rubber for the handle. This makes it easier to grip and turn. Avoid using weak plastic, as it won’t last long.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Rebuilding, Specifically Focusing On Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe rebuilding and chuck keys: 1. What is a chuck key? A chuck key is a tool that helps us tighten or loosen the parts of a lathe. 2. How do we use a chuck key? We insert the chuck key into the chuck and turn it to hold or release the material. 3. Why do we need a chuck key? We need a chuck key to keep things secure while the lathe spins. 4. What can happen if we lose a chuck key? If we lose a chuck key, we might not be able to change materials safely. 5. Can we make a new chuck key? Yes, we can make a new chuck key if we have the right materials and tools.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That A Metal Lathe Chuck Key Needs To Be Replaced Or Rebuilt?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should look for a few signs that your metal lathe chuck key needs help. First, if it feels loose or wobbly, it’s a problem. Second, check for any cracks or chips on the key. If the handle is hard to turn, it might be wearing out. Finally, if it doesn’t hold the tools tightly anymore, you need to replace it.”}},{“@type”: “Question”,”name”: “How Can I Determine The Correct Size And Type Of Chuck Key For My Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right size and type of chuck key for your metal lathe, first check your lathe’s manual. It usually has details about the chuck key you need. You can measure the chuck to see if it is big or small. If you’re still not sure, ask someone at a tool store for help. They can help you find the right one!”}},{“@type”: “Question”,”name”: “What Steps Should I Follow To Properly Rebuild And Maintain A Chuck Key For Optimal Performance On My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild and maintain a chuck key for your metal lathe, first, clean it with a cloth. Check for any broken parts or rust. If you find any, replace them with new pieces. Always keep the chuck key lubricated with a small amount of oil. Finally, store it in a safe place when not in use.”}},{“@type”: “Question”,”name”: “Are There Any Safety Precautions I Should Consider When Working With The Chuck Key On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the chuck key on a metal lathe, always be cautious. Make sure the lathe is turned off before you start. Keep your hands away from the moving parts. Never leave the chuck key in the chuck, as it can fly out and hurt someone. Always wear safety glasses to protect your eyes.”}},{“@type”: “Question”,”name”: “What Materials Are Recommended For Constructing Or Restoring A Durable Chuck Key For Heavy-Duty Metal Lathe Use?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For making a strong chuck key for a metal lathe, you should use good metals like steel. Steel can handle heavy use without breaking. You might also want to use rubber for the handle. This makes it easier to grip and turn. Avoid using weak plastic, as it won’t last long.”}}]}