Have you ever wondered how machines like lathes work? A metal lathe is a fascinating tool used in many shops. It shapes metal into parts we often take for granted. But what happens when the lathe breaks down? Do you throw it away? Surprisingly, you can rebuild it and bring it back to life!

This article will focus on lathe rebuilding, especially the metal lathe compound rest. The compound rest is a key part of the lathe. It helps with precise movements when cutting metal. Without it, your projects could go wrong.

Many people don’t know that rebuilding a lathe can be a rewarding experience. Imagine taking a broken machine and turning it into something useful again. It’s like a fun puzzle that you get to solve! So, are you ready to dive into the world of lathe rebuilding?

Lathe Rebuilding: Enhancing Metal Lathe Compound Rest Performance

Understanding Lathe Rebuilding: The Metal Lathe Compound Rest

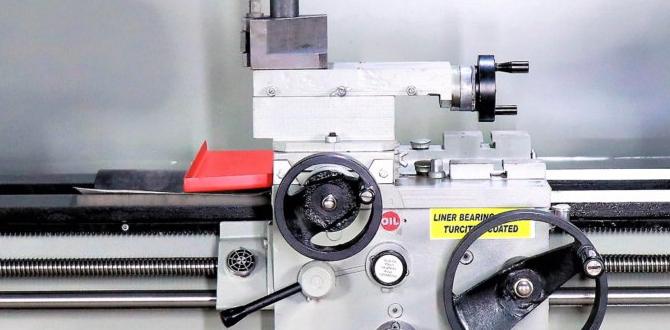

Rebuilding a metal lathe’s compound rest can greatly enhance its accuracy and performance. Did you know that the compound rest helps in setting precise angles for cutting? By restoring this part, users can improve their projects’ quality. Key steps include cleaning, replacing worn parts, and adjusting for smooth movement. A well-maintained compound rest not only extends the lathe’s life but also boosts creativity in metalworking. Why not dive into the world of lathe rebuilding and see what you can create?Understanding the Metal Lathe Compound Rest

Definition and purpose of the compound rest. Importance of the compound rest in machining.The compound rest is an important part of a metal lathe. It helps move the cutting tool closer to the workpiece. This movement allows for precise shaping of metal. Without the compound rest, accurate cutting would be much harder.

The compound rest is vital for machining due to the following reasons:

- Precision: It allows for exact cuts.

- Versatility: It can be adjusted for different angles.

- Efficiency: It speeds up the machining process.

Machinists rely on the compound rest for many tasks. It helps in creating complex shapes and fine details. Every adjustment counts for better results.

Why is the compound rest essential?

The compound rest is essential because it improves accuracy and efficiency. It makes complicated cuts easier to achieve.

Common Issues with Metal Lathe Compound Rests

Identifying signs of wear and damage. Discussing the impact of poor performance on machining.Seeing signs of wear on your metal lathe’s compound rest can be a bit like spotting a sock on a washing line—something’s off! Common problems include rust, chips, or loose screws. These issues can make your lathe behave like a stubborn mule, causing poor cuts and uneven surfaces. Better watch out! A worn compound rest can turn a precise project into a wobbly disaster. Keep an eye out and keep your machine happy!

| Signs of Wear | Impact on Performance |

|---|---|

| Rust | Can lead to corrosion and damage |

| Loose Screws | Causes instability and inaccurate cuts |

| Chips | Results in rough finishes |

Checking these key points can save you much time and effort. Remember, a little maintenance goes a long way—like watering a plant, but way less messy!

Essential Tools and Materials for Rebuilding

List of tools required for the rebuilding process. Recommended materials for a successful rebuild.Rebuilding a metal lathe needs some important tools and materials. You need the right items to do a good job. Here’s a list of essential tools:

- Wrenches

- Screwdrivers

- Files

- Micrometer

- Caliper

- Drill bits

- Sandpaper

Also, consider these materials:

- Replacement screws

- Lubricants

- Sealants

- O-Rings

What tools do I need for lathe rebuilding?

You need basic tools like wrenches, screwdrivers, and files to rebuild a lathe.Step-by-Step Rebuilding Process

Disassembly of the compound rest. Cleaning and inspection of components. Repairing or replacing wornout parts.Start by removing the compound rest from the metal lathe. Carefully take it apart, noting where each piece goes. After disassembly, clean all parts using a soft cloth. Look closely for any damage or wear. Replace or repair parts that are too worn out. This ensures everything works properly. Remember, taking your time helps you do a better job!

What should I do first in the rebuilding process?

Start by disassembling the compound rest carefully. Keep track of your parts for easier reassembly. Always clean parts before inspection!

Steps to Take:

- Remove the compound rest.

- Clean each component.

- Inspect for wear and tear.

- Repair or replace as needed.

Aligning the Compound Rest for Optimal Performance

Techniques for accurate reassembly. Tips for checking alignment postrebuild.Getting the compound rest back together can feel like solving a puzzle, but don’t worry, it’s easier than finding Waldo! Start by checking all the parts for wear or damage. Lay everything out like it’s a fun game of Tetris. In your reassembly, make sure everything fits snugly; no wobbles allowed!

| Tip | Description |

|---|---|

| Use a Dial Indicator | This tool helps check if everything lines up perfectly. |

| Loosen First | When adjusting, always loosen bolts before you tighten them! |

After rebuilding, check alignment. A good rule of thumb? If it doesn’t wiggle or jiggle, you’re golden! Missing that perfect alignment? It might make your lathe behave like it drank too much coffee—jumpy and unpredictable. So, take your time for the best results!

Maintenance Tips for Longevity

Best practices for maintaining a rebuilt compound rest. Regular checks and preventative measures to avoid future issues.Taking care of your rebuilt compound rest is like keeping your pet goldfish happy—frequent attention is key! Regular checks will help catch tiny issues before they turn huge. Make sure to clean it often, and check for any unusual noises. A little oil can go a long way! Preventative measures save you from larger repairs down the road. A quick chart can help you remember what to check:

| Maintenance Task | Frequency |

|---|---|

| Clean the rest | Weekly |

| Check for wear | Monthly |

| Lubricate moving parts | Every 3 months |

Following these tips will keep your lathe running smoothly and can even save money in the long run! Remember, a happy lathe makes for better projects—and less grumpy tool owners!

Upgrading Your Compound Rest

Options for modern upgrades and enhancements. Benefits of upgrading for improved machining efficiency.Upgrading your compound rest opens doors to new possibilities. Modern upgrades improve precision and efficiency. This means smoother cuts and faster work. Consider these options:

- New materials for durability

- Enhanced designs for better movement

- Advanced clamp systems for strong holds

Upgrading can lead to less time spent on tasks. You’ll enjoy better results. By investing in your equipment, you boost overall productivity and creativity.

What are the benefits of upgrading the compound rest?

Upgrading your compound rest increases machining efficiency and accuracy. A well-upgraded lathe can save you time and effort, making each task easier and more enjoyable.

Case Studies and User Experiences

Reallife examples of successful rebuilds. Common challenges faced and solutions applied.Many users have shared stories of成功的lathe重建. For example, one person turned a broken machine into a fully functional metal lathe. They faced common challenges, like finding the right parts. However, they used online forums and repair guides for help. Another user struggled with rust issues, which they solved with a good cleaning and proper lubrication. Their tips show that with patience, anyone can rebuild their own lathe!

What are some common challenges in lathe rebuilding?

Common challenges include:

- Finding replacement parts

- Dealing with rust

- Adjusting the compound rest

Each of these can be fixed with helpful resources and a bit of effort!

Conclusion

In conclusion, rebuilding a metal lathe’s compound rest can improve your machine’s accuracy and performance. You gain better control and precision. It’s a rewarding project that enhances your skills. If you’re interested, explore tutorials or guidebooks to get started. Investing time in your lathe will pay off in your future projects. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Rebuilding A Metal Lathe Compound Rest:Sure! If you want to rebuild a metal lathe compound rest, here are some things to think about. First, you will need to gather all the parts you need. Then, clean each piece carefully. After that, put everything back together in the right order. Finally, test it to see if it works well. Have fun!

Sure! Just give me the question you want answered, and I’ll help you with it.

What Are The Common Signs That Indicate A Compound Rest On A Metal Lathe Needs To Be Rebuilt?You can tell a compound rest on a metal lathe needs rebuilding if it moves unevenly. If you see rust or dirt, that’s another sign. You might also notice that the tool does not hold its position well. If it’s hard to move or makes strange noises, it needs fixing. These signs mean it’s time to take a closer look!

What Tools And Materials Are Essential For Effectively Rebuilding The Compound Rest Of A Metal Lathe?To rebuild the compound rest of a metal lathe, you need a few important tools and materials. First, use a screwdriver and a wrench to take things apart. You will also need a file to smooth out rough edges. Don’t forget lubrication oil to help the parts move easily. Finally, get your safety glasses to protect your eyes while you work.

How Do You Accurately Measure And Align The Components When Rebuilding The Compound Rest To Ensure Precision In Machining?To rebuild the compound rest, first, check each part for wear and damage. Next, use a ruler or caliper to measure how long each piece should be. Align the parts carefully so they fit together well. Tighten the screws gently to hold them in place. Finally, test the movement to make sure everything works smoothly and accurately.

What Are Some Techniques To Improve The Wear Resistance Of The Compound Rest During The Rebuilding Process?To make the compound rest stronger, you can use special coatings. These coatings help protect it from wear. You can also use harder materials for parts. Another technique is to smooth surfaces to reduce friction. This way, your compound rest lasts longer!

Can You Provide Step-By-Step Instructions For Disassembling, Repairing, And Reassembling A Compound Rest On A Metal Lathe?Sure! Here’s how to work with a compound rest on a metal lathe. 1. First, turn off the lathe and unplug it. Safety is important! 2. Use a wrench to loosen and remove the screws holding the compound rest. Keep the screws in a safe place. 3. Gently lift the compound rest off the lathe. If something is stuck, check for any hidden screws. 4. Look for any broken parts. If you find anything damaged, you can fix or replace it. 5. To put it back together, place the compound rest back on the lathe. 6. Tighten the screws securely. 7. Finally, plug in the lathe and turn it on to test it. You’re done!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Rebuilding A Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! If you want to rebuild a metal lathe compound rest, here are some things to think about. First, you will need to gather all the parts you need. Then, clean each piece carefully. After that, put everything back together in the right order. Finally, test it to see if it works well. Have fun!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you want answered, and I’ll help you with it.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Compound Rest On A Metal Lathe Needs To Be Rebuilt?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a compound rest on a metal lathe needs rebuilding if it moves unevenly. If you see rust or dirt, that’s another sign. You might also notice that the tool does not hold its position well. If it’s hard to move or makes strange noises, it needs fixing. These signs mean it’s time to take a closer look!”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Essential For Effectively Rebuilding The Compound Rest Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild the compound rest of a metal lathe, you need a few important tools and materials. First, use a screwdriver and a wrench to take things apart. You will also need a file to smooth out rough edges. Don’t forget lubrication oil to help the parts move easily. Finally, get your safety glasses to protect your eyes while you work.”}},{“@type”: “Question”,”name”: “How Do You Accurately Measure And Align The Components When Rebuilding The Compound Rest To Ensure Precision In Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild the compound rest, first, check each part for wear and damage. Next, use a ruler or caliper to measure how long each piece should be. Align the parts carefully so they fit together well. Tighten the screws gently to hold them in place. Finally, test the movement to make sure everything works smoothly and accurately.”}},{“@type”: “Question”,”name”: “What Are Some Techniques To Improve The Wear Resistance Of The Compound Rest During The Rebuilding Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the compound rest stronger, you can use special coatings. These coatings help protect it from wear. You can also use harder materials for parts. Another technique is to smooth surfaces to reduce friction. This way, your compound rest lasts longer!”}},{“@type”: “Question”,”name”: “Can You Provide Step-By-Step Instructions For Disassembling, Repairing, And Reassembling A Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s how to work with a compound rest on a metal lathe. 1. First, turn off the lathe and unplug it. Safety is important! 2. Use a wrench to loosen and remove the screws holding the compound rest. Keep the screws in a safe place. 3. Gently lift the compound rest off the lathe. If something is stuck, check for any hidden screws. 4. Look for any broken parts. If you find anything damaged, you can fix or replace it. 5. To put it back together, place the compound rest back on the lathe. 6. Tighten the screws securely. 7. Finally, plug in the lathe and turn it on to test it. You’re done!”}}]}