Have you ever watched a metal lathe in action? It’s fascinating to see how it shapes metal. But what happens when your lathe simply stops working? That’s where lathe rebuilding comes into play, especially when it comes to the often-overlooked pulley.

Many people think of lathes as sturdy machines that last forever. However, like any tool, they need care. The pulley is a key part that can wear out over time. This can cause problems, leading to inefficiency.

Imagine trying to create the perfect piece of metal, but your lathe won’t cooperate. It can be frustrating, right? By focusing on lathe rebuilding, especially the pulley, we can bring these machines back to life.

In this article, discover how to troubleshoot your metal lathe and give it a new lease on life. You’ll learn tips for rebuilding the pulley and hear stories from those who have done it. Get ready to dive into the amazing world of lathe rebuilding!

Lathe Rebuilding: Metal Lathe Pulley Guide And Tips

Lathe Rebuilding: Understanding Metal Lathe Pulley

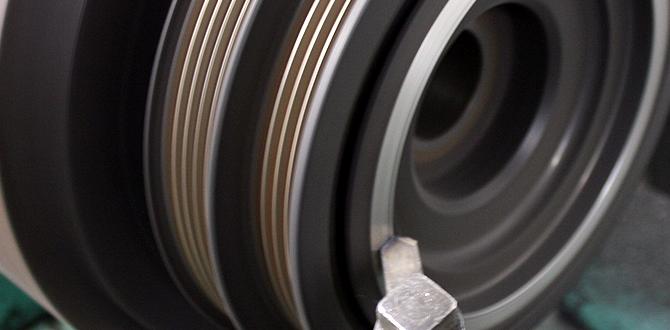

Rebuilding a metal lathe can seem complicated, but it offers great rewards. One crucial part is the pulley. This simple device helps transmit power from the motor to the spindle. Did you know that the right pulley can improve your lathe’s efficiency? Finding and installing the correct pulley can make a big difference in performance. Whether you’re a hobbyist or a pro, learning about lathe pulleys helps you keep your projects running smoothly.Understanding Lathe Rebuilding

Definition and importance of lathe rebuilding. Common reasons for rebuilding a lathe.Lathe rebuilding is like giving your favorite toy a makeover! It means fixing a lathe to make it work better and last longer. This is important because a well-maintained lathe can help produce quality items. You wouldn’t want a wobbly wheel on your bike, right? Common reasons for rebuilding include worn parts, mechanical issues, or simply to upgrade old technology. It’s like giving your old car a new engine! Here’s a quick look:

| Reason for Rebuilding | Details |

|---|---|

| Worn Parts | Over time, parts get tired and need replacements. |

| Mechanical Issues | Sometimes parts break or don’t work well together. |

| Upgrades | New tech can make old machines work like superheroes! |

Identifying Issues with Your Lathe Pulley

Signs that indicate pulley problems. How to assess the condition of the pulley system.Bad lathe pulleys can cause problems while working. Watch out for these signs:

- Unusual noises like grinding or squeaking.

- Wobbling or shaking while spinning.

- Visible wear or damage on the pulley.

How can I tell if my lathe pulley needs attention?

Check for noise, vibrations, or visible damage to know if your lathe pulley needs fixing. Regular checks help catch issues early, making your work safer and smoother.

Necessary Tools and Equipment for Rebuilding

Essential tools needed for lathe rebuilding. Safety equipment requirements.Rebuilding a lathe isn’t a walk in the park, but the right tools make it much easier. You’ll need some basic gear like a wrench, screwdriver, and measuring tape. Don’t forget a tough hammer for when the machine misbehaves! Additionally, safety is key. Always wear safety goggles and gloves, unless you like your fingers the way they are! Here’s a quick look at what you’ll need:

| Tool/Equipment | Purpose |

|---|---|

| Wrench | Tightening and loosening bolts |

| Screwdriver | Creating or removing screws |

| Measuring Tape | Getting accurate measurements |

| Safety Goggles | Protecting your eyes |

| Gloves | Safeguarding your hands |

With these tools, you’ll be well on your way to becoming a lathe master!

Step-by-Step Process for Rebuilding Metal Lathe Pulley

Detailed breakdown of the rebuilding process. Tips for maintaining accuracy and consistency.Rebuilding a metal lathe pulley is like a fun science project for grown-ups! Start by disassembling the pulley carefully. Make sure to label all the parts, like you’re organizing your toy box. Next, clean each component using a soft brush and some oil—like giving your lathe a nice spa day. Reassemble the parts, checking for accuracy. Use a micrometer for consistency. Remember: a happy lathe makes happy projects! Keep your tools sharp, and your lathe will be the MVP of your shop.

| Step | Action | Tip |

|---|---|---|

| 1 | Disassemble | Label parts |

| 2 | Clean | Use soft brush |

| 3 | Reassemble | Check accuracy |

Finally, to keep everything running smoothly, regularly check for wear and tear. Remember: if it squeaks, something’s not right!

Common Mistakes to Avoid During Rebuilding

List of frequent errors made during the rebuilding process. How to rectify common mistakes.Rebuilding a lathe can be a fun adventure, but mistakes can make it feel like a comedy show gone wrong! One common mistake is forgetting to clean parts before reassembly. This can lead to unwanted surprises later. Another error is misaligning the pulley, which can cause wobbling—like trying to dance on a tightrope. To fix these blunders, always double-check your work and use a clear guide. Here’s a handy table to keep you on track:

| Error | Fix |

|---|---|

| Not cleaning parts | Wipe everything down before starting |

| Misaligned pulley | Use a square to ensure straightness |

| Ignoring measurements | Measure twice, cut once |

Remember, rebuilding is like making a sandwich—layer it right, or you’ll end up with a soggy mess!

Cost Analysis of Lathe Rebuilding

Breakdown of costs involved in rebuilding a metal lathe. Comparison to purchasing a new lathe.Understanding the costs of rebuilding a metal lathe is crucial for budget planning. The main expenses typically include:

- Parts and materials

- Labor costs

- Shipping fees

In contrast, buying a new lathe can be much more expensive. Rebuilding can save money while improving quality. It’s often about making wise choices and investing where it matters most.

How Much Does It Cost to Rebuild a Lathe?

The average cost to rebuild a lathe can be around $2,500 to $5,000. However, this can vary based on the machine’s condition and the parts needed.

Maintaining Your Rebuilt Lathe Pulley System

Best practices for ongoing maintenance. Schedule and checklists for regular upkeep.Keeping your rebuilt lathe pulley system in tip-top shape is essential for smooth operation. A few simple practices can make a world of difference. Start with regular inspections. Check for wear and tear, and listen for strange noises; they might just be your lathe singing a tune! Set up a maintenance schedule, and stick to it like glue. Here are some key tasks:

| Task | Frequency |

|---|---|

| Inspect belts and pulleys | Every month |

| Lubricate moving parts | Every three months |

| Clean the machine | Every week |

By following this checklist, you’ll keep your lathe running smoothly and possibly avoid a “lathe-ocalypse.” After all, no one wants to deal with a broken lathe while chasing their dreams of metalworking glory!

FAQs About Lathe Rebuilding

Common questions and expert answers. Troubleshooting tips for additional issues.Have you ever wondered about the ins and outs of lathe rebuilding? Many people have questions! For instance, “What’s the best way to fix a squeaky pulley?” The answer is to check the bearings. They might need a bit of grease or a good cleaning! Another popular question is, “How do I know if my lathe is out of alignment?” Well, if your projects look like they were made on roller skates, it’s time to adjust things! Below is a handy table with more common questions and their quick fixes:

| Question | Answer |

|---|---|

| How often should I clean my lathe? | After every use, to keep it shiny and happy. |

| What if the motor stops suddenly? | Check the power supply; it might be taking a nap! |

| Can I rebuild my lathe myself? | Yes! With some patience, you can be your own lathe superhero. |

These tips can help you tackle common issues and keep your metal lathe in tip-top shape!

Resources for Further Learning

Recommended books, tutorials, and forums. Online communities and support groups for lathe enthusiasts.To dive deeper into lathe rebuilding metal lathe pulley, explore these helpful resources:

- Books: Look for titles like “The Complete Guide to Metalworking” for easy tips.

- Tutorials: Videos on platforms like YouTube offer step-by-step guides.

- Forums: Join discussions on sites like Reddit about lathes.

- Support Groups: Connect with fellow enthusiasts on Facebook groups.

These resources offer valuable information, share experiences, and build friendships in the lathe community.

What are good beginner books on lathes?

Check out “Metalworking Basics for Beginners”. It’s an easy read with simple projects.

Conclusion

In conclusion, rebuilding your metal lathe pulley can significantly improve performance. Start by assessing its condition. Clean and replace worn parts for better efficiency. Regular maintenance keeps your lathe running smoothly. If you’re curious, explore guides or tutorials for a hands-on project. You can master this skill and enhance your metalworking experience! Happy rebuilding!FAQs

Here Are Five Questions Related To Rebuilding A Metal Lathe Pulley:Sure! When rebuilding a metal lathe pulley, first, you need to gather your tools. You’ll probably need wrenches and some oil. Next, take apart the old pulley carefully. Make sure to clean all parts before putting them back together. Finally, check that everything works properly before using it again.

Sure! Just let me know what question you want me to answer, and I’ll help you out.

What Are The Common Signs That Indicate A Metal Lathe Pulley Needs Rebuilding Or Replacement?If your metal lathe pulley is making strange noises, it’s a sign something is wrong. You might also see cracks or wear on the pulley. If it shakes or wobbles while working, it may need fixing. Finally, if the belt slips off too often, it’s time to replace or rebuild it.

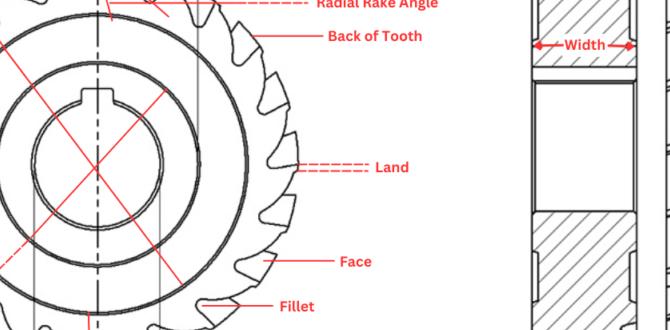

How Can You Accurately Measure The Dimensions Of An Existing Pulley For A Rebuild?To measure a pulley, start by taking a ruler or measuring tape. First, measure the diameter from one side to the other. Then, measure the width, which is how thick the pulley is. If there are grooves, measure their depth and width too. Write down these numbers so you can use them for the rebuild.

What Types Of Materials Are Best Suited For Fabricating New Pulleys In Metal Lathe Rebuilding Projects?For making new pulleys in a metal lathe project, you can use strong metals like aluminum or steel. Aluminum is light and easy to work with. Steel is very strong and lasts a long time. Both materials will help your pulleys work well.

What Are The Key Steps Involved In Disassembling And Reassembling The Pulley System On A Metal Lathe?To take apart the pulley system on a metal lathe, first, turn off the machine and unplug it. Next, you need to carefully unscrew any screws holding the pulley in place. After that, you can gently remove the pulley system. When you put it back together, place the pulley back where it belongs. Finally, screw everything tight and plug the lathe back in.

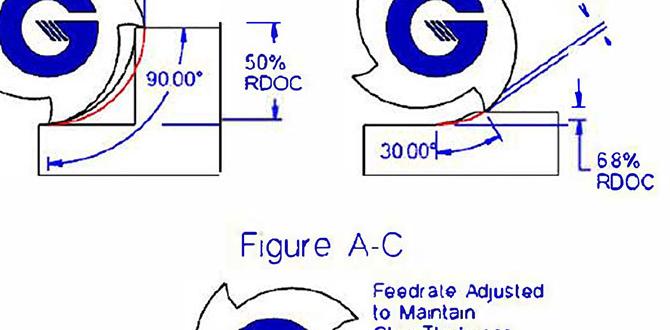

How Can You Ensure Proper Alignment And Tension Of The Pulley System After Rebuilding A Metal Lathe?To make sure the pulley system works well after fixing your metal lathe, start by checking the alignment. You can do this by looking at the pulleys and making sure they line up straight. Next, adjust the tension by tightening or loosening the belts until they’re snug but not too tight. Finally, spin the pulleys by hand to see if they move smoothly. This way, your lathe will work better and last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Rebuilding A Metal Lathe Pulley:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When rebuilding a metal lathe pulley, first, you need to gather your tools. You’ll probably need wrenches and some oil. Next, take apart the old pulley carefully. Make sure to clean all parts before putting them back together. Finally, check that everything works properly before using it again.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Metal Lathe Pulley Needs Rebuilding Or Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe pulley is making strange noises, it’s a sign something is wrong. You might also see cracks or wear on the pulley. If it shakes or wobbles while working, it may need fixing. Finally, if the belt slips off too often, it’s time to replace or rebuild it.”}},{“@type”: “Question”,”name”: “How Can You Accurately Measure The Dimensions Of An Existing Pulley For A Rebuild?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure a pulley, start by taking a ruler or measuring tape. First, measure the diameter from one side to the other. Then, measure the width, which is how thick the pulley is. If there are grooves, measure their depth and width too. Write down these numbers so you can use them for the rebuild.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Best Suited For Fabricating New Pulleys In Metal Lathe Rebuilding Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For making new pulleys in a metal lathe project, you can use strong metals like aluminum or steel. Aluminum is light and easy to work with. Steel is very strong and lasts a long time. Both materials will help your pulleys work well.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Disassembling And Reassembling The Pulley System On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take apart the pulley system on a metal lathe, first, turn off the machine and unplug it. Next, you need to carefully unscrew any screws holding the pulley in place. After that, you can gently remove the pulley system. When you put it back together, place the pulley back where it belongs. Finally, screw everything tight and plug the lathe back in.”}},{“@type”: “Question”,”name”: “How Can You Ensure Proper Alignment And Tension Of The Pulley System After Rebuilding A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the pulley system works well after fixing your metal lathe, start by checking the alignment. You can do this by looking at the pulleys and making sure they line up straight. Next, adjust the tension by tightening or loosening the belts until they’re snug but not too tight. Finally, spin the pulleys by hand to see if they move smoothly. This way, your lathe will work better and last longer!”}}]}