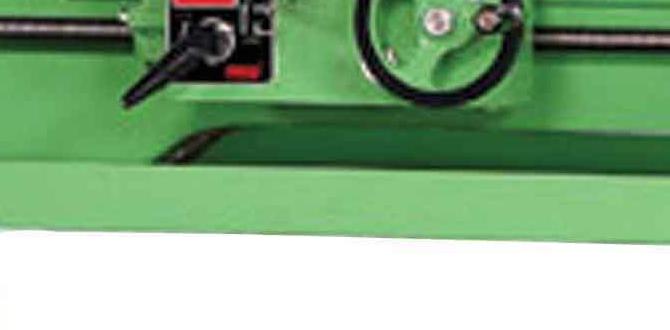

Have you ever wondered how metalworkers create such precise pieces? One crucial part of the process is the lathe. This machine shapes metal with incredible accuracy. But like any tool, it needs attention. One key area often overlooked is the tailstock alignment.

Imagine trying to make a perfect cut, but your tool is misaligned. Frustrating, right? Proper lathe rebuilding helps fix that. Tailstock alignment can make or break your project. It ensures that pieces fit together just right.

Many think that proper alignment is complicated. But it doesn’t have to be! Learning about this process can be exciting. You can save time and improve your work quality. Let’s explore the world of lathe rebuilding and discover how tailstock alignment can elevate your metalwork.

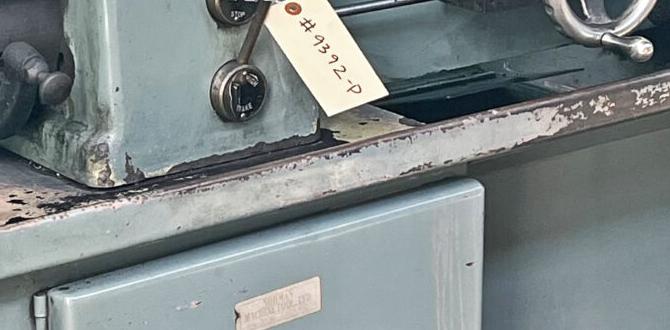

Lathe Rebuilding: Metal Lathe Tailstock Alignment Tips

Lathe Rebuilding: Metal Lathe Tailstock Alignment

Achieving proper tailstock alignment on a metal lathe is essential for precision work. Misalignment can affect the quality of cuts and lead to wasted materials. To align the tailstock, check the bed for level and adjust screws as needed. Did you know that even slight misalignments can cause major issues? Regular checks help maintain accuracy. Understanding this key process can greatly enhance your lathe rebuilding projects and improve overall performance.Understanding Tailstock Alignment

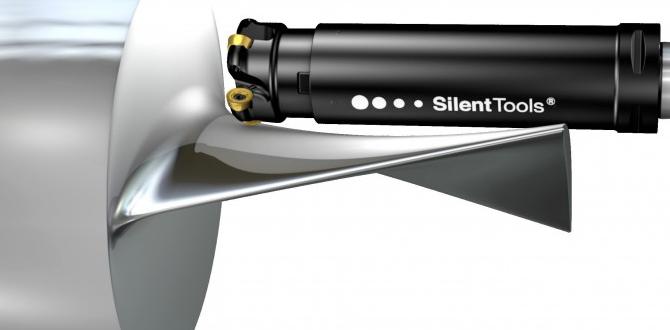

Importance of tailstock alignment for precision machining. Common issues caused by misalignment.Imagine trying to hit a bullseye with your eyes closed—tough, right? Well, that’s what misaligned tailstocks do in precision machining! They mess up your work and can cause awkward cuts or uneven finishes. If your tailstock is off, your projects may turn out like a lopsided cake! Proper alignment keeps everything steady, ensuring your work is sharp and smooth.

| Issue | Effect |

|---|---|

| Misalignment | Poor cut quality |

| Excessive wear | Shorter tool life |

| Vibration | Reduced accuracy |

In short, aligning your tailstock is key to avoiding these headaches! Remember: a happy tailstock makes for a happy machinist!

Tools and Equipment Needed

List of essential tools for tailstock alignment. Recommended equipment for accurate measurements.Aligning a tailstock can feel tricky, but with the right tools, it’s like riding a bike—once you get it, you’ve got it! To start, gather these essentials: a dial indicator for precision, a straightedge for measuring flat surfaces, and a wrench set for adjustments. Don’t forget a trusty level to avoid any wobbles that could leave you feeling off-balance!

| Tool | Purpose |

|---|---|

| Dial Indicator | For precise measurements |

| Straightedge | To check flatness |

| Wrench Set | For making adjustments |

| Level | To ensure balance |

With these tools in hand, aligning your tailstock will be easier than convincing a cat to take a bath!

Steps to Check Tailstock Alignment

Detailed procedure for assessing current tailstock alignment. Tips for ensuring accurate measurements.Checking tailstock alignment is essential for accurate machining. Here’s how to do it:

- Start with a test bar. Place it in the lathe and align it with the tailstock.

- Measure the distance from the end of the bar to the tailstock. Use a caliper for precision.

- Adjust the tailstock if necessary. Ensure it aligns perfectly with the test bar.

For accurate measurements, keep the tool steady. Use good lighting and check twice. Small errors can lead to big mistakes. This process takes time but is very important!

How can I tell if my tailstock is aligned correctly?

To know if your tailstock is aligned correctly, align a test bar and measure the distance. If both ends are even, it’s aligned. If not, adjust accordingly. Checking is key to smooth machining!

Adjusting the Tailstock

Stepbystep guide for making adjustments. Common adjustment techniques and methods.To adjust the tailstock of your lathe, follow these steps:

- First, check for any loose screws or parts.

- Next, move the tailstock to align it with the spindle.

- Then, use the tailstock adjustment screw to make small changes.

- Finally, test the alignment by using a piece of scrap material.

Common techniques include aligning with the spindle center and leveling the tailstock base. Ensure everything is tight and secure. Remember, regular checks help maintain accuracy for better results.

How often should you adjust the tailstock?

You should adjust the tailstock every few months or after heavy use. Regular adjustments help keep your lathe working well.

Testing for Accuracy post-Adjustment

Methods to verify correct alignment after adjustments. Ideal scenarios and measurements for testing.After making adjustments to your lathe, it’s crucial to ensure everything is spot on. First, use a dial indicator to measure the tailstock alignment. Place it against the bed of the lathe and check for any gaps. Your aim? A perfect zero reading! For ideal results, repeat this in multiple positions. This way, you’ll catch any sneaky misalignments. Don’t be surprised if it looks funnier than your cat trying to chase a laser pointer!

| Measurement Method | Ideal Result |

|---|---|

| Dial Indicator | Zero Reading |

| Test Cuts | Smooth Finish |

Maintaining Tailstock Alignment

Best practices for regular maintenance and checks. Preventative measures to avoid future misalignment.Keeping your tailstock aligned is important for smooth operation. Regular checks make a big difference. Here are some best practices:

- Check alignment every month.

- Clean the tailstock and bed to prevent debris buildup.

- Lubricate moving parts to keep them working well.

- Use a dial indicator to measure alignment accurately.

To avoid future misalignment, consider these tips:

- Adjust the tailstock after heavy use.

- Store the lathe in a stable, vibration-free area.

- Avoid over-tightening screws and bolts.

Following these simple steps can keep your lathe running smoothly and extend its life!

Why is tailstock alignment important?

Tailstock alignment ensures accuracy and efficiency in machining tasks. Misalignment can lead to poor cuts and damaged materials.

Common Problems and Solutions

Typical issues encountered during tailstock alignment. Quick fixes and troubleshooting tips.Tailstock alignment can sometimes feel like a dance with two left feet. Common issues include misalignment, wobbling, or the tailstock not moving smoothly. These are like pesky ants at a picnic, but don’t panic! A simple adjustment or a good clean can work wonders. Here’s a quick guide:

| Problem | Quick Fix |

|---|---|

| Misalignment | Adjust the tailstock set screws. |

| Wobbling | Tighten the tailstock and check for debris. |

| Difficulty moving | Lubricate the rail and tailstock. |

With these tips, your lathe tailstock can glide like a duck on a pond. Remember, fixing these issues early will keep your projects on track and save you from future headaches!

Case Studies and Real-World Examples

Examples of successful tailstock alignment in various applications. Lessons learned from common rebuilding projects.Successful lathe rebuilding metal lathe tailstock alignment can be seen in many real-world cases. For instance, a local machine shop improved their output by 30% after correcting their tailstock. Another example shows that proper alignment helped a hobbyist create perfect round parts. Here are some lessons learned:

- Always check your tailstock after adjustments.

- Use precision tools for measuring alignment.

- Take your time to avoid mistakes.

Each project teaches valuable lessons on how to achieve better results.

What are some examples of tailstock alignment success?

Successful examples often show increased accuracy and efficiency in machining tasks. Shops and hobbyists alike report better performance after alignment adjustments.

Expert Tips for Lathe Rebuilding

Insights from experienced machinists on tailstock alignment. Advanced techniques for enhanced precision and reliability.Getting the tailstock right is key for great lathe work. Experienced machinists recommend a few smart tricks. First, always check the alignment before starting. Use a dial indicator to ensure it is spot-on. This method reduces errors. Also, use shims to adjust if needed. Here are some quick tips:

- Check the tailstock regularly.

- Adjust with shims for better fit.

- Calibrate with a dial gauge.

These steps boost your lathe’s precision.

What is the best way to align the tailstock?

The best way to align the tailstock is to use a dial indicator and make necessary adjustments with shims. Regular verification is essential for improved accuracy.

Conclusion

In conclusion, aligning the tailstock on a rebuilt metal lathe is crucial for accurate machining. You should check the alignment regularly to ensure better results. This process helps in preventing errors, saving time, and improving your work. Now, you can explore more resources or guides to help you with lathe alignment and enjoy becoming a better machinist!FAQs

Sure! Here Are Five Questions Related To Lathe Rebuilding And Tailstock Alignment:Sure! When rebuilding a lathe, we check all its parts. We want everything to fit and work together well. Tailstock alignment helps us make straight cuts. If it’s off, it can cause mistakes in our work. It’s important to keep our tools in good shape!

Sure! Please share the question you’d like me to answer.

What Are The Key Indicators That A Lathe Tailstock Is Misaligned And Requires Adjustment During A Rebuild?You can tell a lathe tailstock is misaligned if you see uneven cuts on your workpiece. If the tailstock wobbles or shakes while you work, that’s another sign. Also, check if the point of the tailstock does not line up with the lathe’s center. If you notice these things, it’s time to adjust the tailstock.

Sure! Please provide the question you’d like me to answer.

How Can You Accurately Measure Tailstock Alignment On A Metal Lathe To Ensure Precision Machining?To check if the tailstock is lined up on a metal lathe, we can use a test bar. First, put the test bar in the lathe and tighten it. Then, rotate the bar and see if there’s any wobble. If it wobbles, adjust the tailstock until it spins smoothly. This helps us make sure our cuts are precise and the work piece is perfect.

Sure! Please provide the question you’d like me to answer.

What Tools And Techniques Are Commonly Used To Realign A Lathe Tailstock During A Rebuilding Process?To realign a lathe tailstock, we often use special tools. One tool is a dial indicator, which helps measure tiny changes. We can also use a straightedge to check if the tailstock is straight. To fix it, we may adjust screws to move the tailstock into the right position. Finally, we double-check everything to make sure it’s just right!

Sure! Please provide the question you’d like me to answer.

How Does Tailstock Misalignment Affect The Quality And Accuracy Of Machined Parts?When the tailstock is not lined up right, it can cause problems when we make parts. The parts might not fit together well. This misalignment can also lead to uneven shapes or sizes. If we want our parts to work perfectly, we need to make sure everything is lined up correctly. This way, we can create better quality products.

Sure! Please provide the question you’d like me to answer.

What Step-By-Step Procedures Should Be Followed To Properly Align A Tailstock After A Lathe Rebuilding Project?To align a tailstock after rebuilding your lathe, follow these steps: 1. **Check the bed**: Make sure the lathe bed is level and clean. 2. **Use a center**: Put a test bar or a center in the tailstock. 3. **Adjust the tailstock**: If it doesn’t line up with the headstock, move it slightly to the right or left. 4. **Tighten the screws**: Once it’s aligned, tighten all the screws to hold it in place. 5. **Test again**: Spin the test bar to ensure it runs straight.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Rebuilding And Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When rebuilding a lathe, we check all its parts. We want everything to fit and work together well. Tailstock alignment helps us make straight cuts. If it’s off, it can cause mistakes in our work. It’s important to keep our tools in good shape!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Indicators That A Lathe Tailstock Is Misaligned And Requires Adjustment During A Rebuild?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a lathe tailstock is misaligned if you see uneven cuts on your workpiece. If the tailstock wobbles or shakes while you work, that’s another sign. Also, check if the point of the tailstock does not line up with the lathe’s center. If you notice these things, it’s time to adjust the tailstock.”}},{“@type”: “Question”,”name”: ” “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “How Can You Accurately Measure Tailstock Alignment On A Metal Lathe To Ensure Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the tailstock is lined up on a metal lathe, we can use a test bar. First, put the test bar in the lathe and tighten it. Then, rotate the bar and see if there’s any wobble. If it wobbles, adjust the tailstock until it spins smoothly. This helps us make sure our cuts are precise and the work piece is perfect.”}},{“@type”: “Question”,”name”: ” “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Commonly Used To Realign A Lathe Tailstock During A Rebuilding Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To realign a lathe tailstock, we often use special tools. One tool is a dial indicator, which helps measure tiny changes. We can also use a straightedge to check if the tailstock is straight. To fix it, we may adjust screws to move the tailstock into the right position. Finally, we double-check everything to make sure it’s just right!”}},{“@type”: “Question”,”name”: ” “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “How Does Tailstock Misalignment Affect The Quality And Accuracy Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is not lined up right, it can cause problems when we make parts. The parts might not fit together well. This misalignment can also lead to uneven shapes or sizes. If we want our parts to work perfectly, we need to make sure everything is lined up correctly. This way, we can create better quality products.”}},{“@type”: “Question”,”name”: ” “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Step-By-Step Procedures Should Be Followed To Properly Align A Tailstock After A Lathe Rebuilding Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a tailstock after rebuilding your lathe, follow these steps: 1. **Check the bed**: Make sure the lathe bed is level and clean. 2. **Use a center**: Put a test bar or a center in the tailstock. 3. **Adjust the tailstock**: If it doesn’t line up with the headstock, move it slightly to the right or left. 4. **Tighten the screws**: Once it’s aligned, tighten all the screws to hold it in place. 5. **Test again**: Spin the test bar to ensure it runs straight.”}}]}