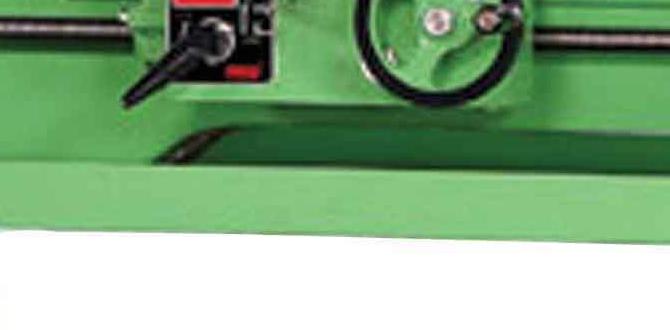

Have you ever seen a metal lathe in action? It’s a powerful machine that shapes and cuts metal with great precision. But, like any machine, it can face problems. That’s where a lathe repair kit comes in. This special kit helps fix common issues, especially in the gear train.

Imagine you’re working on a project and suddenly your lathe stops. Frustrating, right? You might not want to spend a lot of time and money on repairs. A lathe repair kit can save the day! It often includes essential parts and tools to get your lathe back in shape.

Did you know that many hobbyists love to tinker with lathes? They take pride in fixing them and creating amazing things. With a good lathe repair kit, anyone can learn how to maintain their machine. You can join them in this exciting journey of creativity and skill.

In this article, we will explore what makes a lathe repair kit important. We will also dive into the gear train and its role in your lathe’s performance. Let’s discover how to keep your lathe running smoothly!

Essential Lathe Repair Kit For Metal Lathe Gear Train

Lathe Repair Kit for Metal Lathe Gear Train

Looking to repair your metal lathe? A lathe repair kit can be a game-changer. It includes essential parts like gears, belts, and bearings, helping your machine run smoothly again. Did you know that failing gears are often the root of many lathe issues? With a good repair kit, you can save time and money on repairs. Imagine getting back to your projects quickly, all thanks to a well-designed gear train!Components of a Lathe Repair Kit

Breakdown of typical items found in a metal lathe repair kit.. Discussion of the quality and compatibility of components..Repair kits for metal lathes are like toolboxes for superheroes! A typical kit includes shiny gears, belts, and seals, all ready to save the day. Quality matters, so look for parts that fit your lathe like a glove—tight but not too tight. Compatibility is key; mismatched pieces may cause trouble, like a sock with a hole! Here’s a quick look at common components:

| Component | Purpose | Quality Tip |

|---|---|---|

| Gears | Transfer power | Ensure they match your lathe type |

| Belts | Connect moving parts | Choose durable materials |

| Seals | Prevent leaks | Check for tightness and wear |

Using quality parts can extend your lathe’s life. Remember, a happy lathe leads to happy projects!

How to Identify Gear Train Problems

Symptoms indicating issues with the gear train.. Diagnostic steps to determine the specific problem..It’s important to spot signs of trouble in the gear train. Watch for strange noises or difficulty in movement. These can mean there’s an issue. Here are common signs:

- Unusual sounds during operation.

- Inconsistent speed or skipping.

- Excessive vibration of the machine.

- Visible damage to gears.

To diagnose the problem, follow these steps:

- Check for loose connections or broken parts.

- Inspect lubricant levels and add more if needed.

- Test the gears when the machine is running.

- Review the gear alignment for any misalignment.

What are common problems in a gear train?

Common gear train problems include worn-out gears, misalignment, and insufficient lubrication.How can I prevent gear train issues?

- Perform regular maintenance.

- Keep lubricants at appropriate levels.

- Check for wear and tear often.

Step-by-Step Guide for Repairing Gear Train Issues

Detailed instructions on disassembling the gear train.. Repair techniques for common problems..Ready to tackle gear train troubles? First, disassemble the gear train carefully. Start by removing the outer cover. Use a screwdriver to take off screws and gently lift the cover away. Keep all screws safe, or your cat might think they are toys! Next, check for broken gears or wear. Common fixes include replacing damaged gears or tightening loose ones. A quick dab of grease might help too!

| Common Gear Issues | Repair Techniques |

|---|---|

| Broken Gear | Replace with a new one |

| Worn Teeth | Sand down or replace |

| Loose Connections | Tighten screws |

Remember, keeping your lathe happy keeps your projects running smoothly! So, let’s fix that gear train and get back to making cool stuff!

Preventive Maintenance Tips for Lathe Gear Trains

Routine maintenance practices to extend the lifespan of gear trains.. Recommended lubricants and care products..To keep your lathe gear trains in great shape, follow some simple steps. Regular checks and cleaning can really help. Here are some tips you can follow:

- Lubricate the gears often. Use high-quality oil designed for metal lathe gear trains.

- Inspect for wear and tear. Look closely at the gears and replace any that seem damaged.

- Keep the area around the lathe clean. Dust can hurt the gears.

These steps will help your lathe last longer and work better!

What lubricants are best for gear trains?

The best lubricants are usually specially-formulated oils for metal machinery. These oils decrease friction and prevent rust. Make sure to apply them regularly for smooth operation.

Taking care of your lathe gear trains is easy. With the right lubricants and a few simple practices, your machine will serve you well for years!

Choosing the Right Repair Kit for Your Metal Lathe

Factors to consider when selecting a repair kit.. Reviews and comparisons of popular repair kits on the market..Finding a repair kit for your metal lathe can feel like searching for a needle in a haystack. Think about what parts you need first; consider the size and model of your lathe. Then, read reviews to compare kits. Some kits are like Swiss Army knives, packed with everything, while others are a bit barebones. How do you know which one to pick? Check out this handy table:

| Repair Kit | Contents | Price | Rating |

|---|---|---|---|

| Super Lathe Kit | Gears, belts, lubricants | $50 | ⭐⭐⭐⭐⭐ |

| Basic Repair Kit | Gears only | $30 | ⭐⭐⭐⭐ |

| Deluxe Lathe Kit | Gears, belts, tools | $75 | ⭐⭐⭐⭐⭐ |

Check reviews to see what other users say. A great kit can keep your lathe running smoothly, so choose wisely. Your lathe deserves the best!

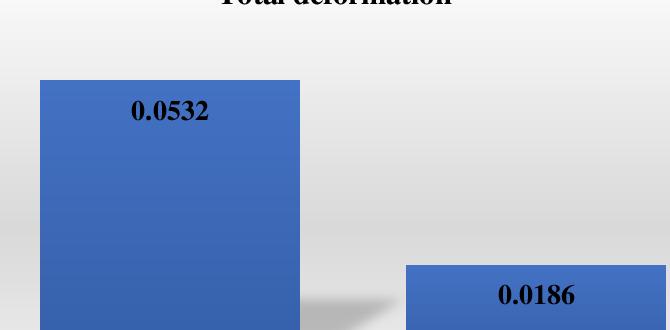

DIY vs Professional Repair Services

Pros and cons of handling repairs yourself versus hiring professionals.. Cost analysis and time investment for both options..Choosing between DIY repairs and hiring a pro can be tough. Each has its strengths and weaknesses. Doing it yourself can save money, but it may take longer if you lack experience. On the other hand, professionals offer expertise, often completing the job faster but at a higher cost. Think about your skills and how much time you can spend. Here’s a quick look:

- DIY Repairs: Cheaper, but time-consuming.

- Pro Services: Quick and reliable, but more expensive.

For some tasks, like using a lathe repair kit metal lathe gear train, it might be worth getting help. Weigh your options to find the best choice for your needs.

How much does it cost to hire a professional?

The cost depends on the job size, but hiring a pro often costs hundreds, while DIY can range from $20 to $200 for materials.

What are some common DIY repairs?

- Changing a faucet

- Fixing loose cabinets

- Painting rooms

Frequently Asked Questions about Lathe Gear Train Repair

Common queries regarding gear train repairs and solutions.. Answers from experienced lathe technicians..Many people have questions about fixing lathe gear trains. Here are some common ones answered by seasoned lathe technicians.

How do I identify issues in my gear train?

Look for strange noises or vibrations. These can signal a problem. Inspecting the gears often reveals wear or damage.

What are some quick fixes?

- Clean the gears. Dust can cause issues.

- Lubricate regularly. This keeps them running smoothly.

- Replace damaged parts. Using a lathe repair kit can make this easier.

How can I avoid future problems?

Perform regular maintenance. A simple checkup can save time and money later.

Conclusion

In summary, a lathe repair kit for the metal lathe gear train is essential for smooth operation. It helps fix wear and tear, ensuring your projects run well. You can save time and money by maintaining your tools. We encourage you to explore more about lathe care, and consider getting a repair kit for your lathe today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits For Metal Lathe Gear Trains:Lathe repair kits help fix the parts inside a metal lathe. A lathe is a machine that shapes metal. If gear parts break, the kit gives you new ones. You can use it to make your lathe work well again. It’s like a toolbox for fixing your machine!

Sure! Please provide the question you’d like me to answer.

What Essential Components Are Typically Included In A Lathe Repair Kit For The Gear Train Of A Metal Lathe?A lathe repair kit for the gear train usually includes gears, bearings, and belts. You might also find a small set of tools like wrenches and screwdrivers. These parts help keep the lathe working smoothly. It’s important to have these items ready if something breaks. We want our machines to run well, so having a repair kit is smart!

How Do You Identify Signs Of Wear Or Damage In The Gear Train Of A Metal Lathe That May Necessitate The Use Of A Repair Kit?To find wear or damage in the gear train of a metal lathe, you should look for a few things. First, check if the gears are noisy when you use the lathe. If you see any cracks or breaks in the gears, that’s a problem. Also, look for parts that are loose or not moving smoothly. If you notice these signs, it might be time to use a repair kit.

What Are The Steps Involved In Replacing Gears Or Components In The Gear Train Of A Metal Lathe Using A Repair Kit?To replace gears in a metal lathe, first, turn off the machine and unplug it. Next, take off the cover so you can see the gears. Then, carefully remove the old gears using tools from your repair kit. After that, put the new gears in their spots and make sure they fit well. Finally, put the cover back on and plug in the lathe to test it.

Are There Specific Maintenance Practices That Can Help Extend The Lifespan Of The Gear Train In A Metal Lathe, Reducing The Need For Repair Kits?Yes, there are ways to take care of the gear train in a metal lathe. You should always keep it clean and free of dust. Check the oil levels regularly and add oil when needed. Tighten any loose parts to prevent wear and tear. By doing this, you help your lathe last longer and need fewer repairs.

How Can One Ensure Compatibility Between A Lathe Repair Kit And A Specific Model Of Metal Lathe, Particularly Regarding Gear Sizes And Materials?To ensure your lathe repair kit matches your metal lathe, you can follow these steps. First, check the model number of your lathe. Then, look for a repair kit that lists that model. Next, compare the gear sizes of both the lathe and the kit to make sure they are the same. Finally, check the materials used in the repair kit to ensure they are strong and suitable for your lathe.