Have you ever wondered how metal lathes work? These machines shape metal into useful items, from parts for cars to intricate tools. However, like any machine, they need care and repair. Getting a lathe repair kit can be a game-changer for anyone who uses metal lathes.

One key part of this kit is the lead screw. It controls the movement of the lathe’s tool. If it breaks, your lathe might not work right. Imagine trying to finish your project only to find that your tool won’t move!

Having a lathe repair kit ready means you can fix it yourself. This saves you time and money. Plus, it can be fun to learn how your lathe works. Fixing things can feel like being a superhero! So, let’s explore what you need in a lathe repair kit and how to use it.

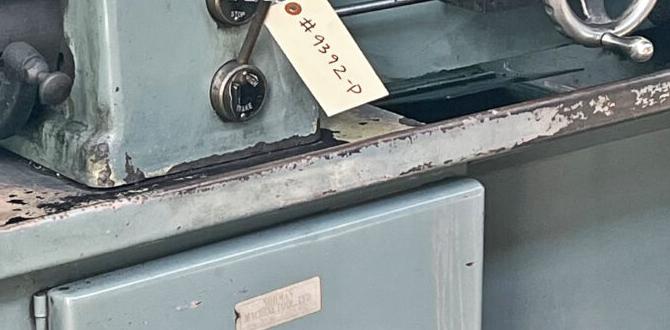

Essential Lathe Repair Kit For Metal Lathe Lead Screw

Understanding Lathe Repair Kit for Metal Lathe Lead Screw

A lathe repair kit for the metal lathe lead screw is essential for maintaining smooth operation. Have you ever dealt with a stubborn lead screw that won’t turn? This kit can save you time and hassle. It usually includes all necessary parts, like nuts and bearings. Regular maintenance can extend your lathe’s life. Did you know that a well-maintained lead screw can improve accuracy? Investing in a repair kit keeps your projects on track!Common Issues with Lathe Lead Screws

Signs of wear and tear in lead screws.. Common problems affecting lathe performance..Lead screws in lathes are important parts. They help move the cutting tool smoothly. However, they can wear out over time. Here are some signs of wear and tear:

- Visible scratches or grooves on the surface.

- Inconsistent movement during operation.

- Unusual noises when the lathe is in use.

These issues can cause problems in lathe performance. Your projects might not come out right. Regular checks can help catch these problems early.

What should I look for in lathe lead screws?

Look for scratches, uneven movement, and noise. These signs can help you know when it’s time for a lathe repair kit.

What is a Lathe Repair Kit?

Definition and purpose of a lathe repair kit.. Key components typically included in repair kits..A lathe repair kit is a handy toolbox for fixing metal lathes, like having a superhero sidekick for your machine. Its main purpose is to keep the lathe running smoothly and to prevent problems that can lead to costly repairs. Think of it as first aid for your metal friend.

Typical kits often include essential parts like gaskets, seals, and bearings. These components help maintain the lead screw’s precision. Without them, your lathe might start sounding like a tired old dog!

| Component | Purpose |

|---|---|

| Gaskets | Prevent leaks and keep things tidy. |

| Seals | Stop dirt and grime from messing up your lathe. |

| Bearings | Keep everything moving smoothly and quietly. |

With the right repair kit, you can avoid turning your lathe into a rusty paperweight. Remember, a happy lathe is a productive lathe!

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit.. Compatibility with various metal lathe models..Choosing a lathe repair kit can be tricky. You must think about a few important things. First, check if the kit is compatible with your metal lathe model. Some kits only fit certain models. You should also look at the quality of the parts. Reliable kits last longer and work better. Finally, see if the kit includes all the parts you need. This will save you time and money.

What should I consider when selecting a lathe repair kit?

Focus on these points:

- Compatibility with your lathe type

- Quality of materials used

- Completeness of the kit

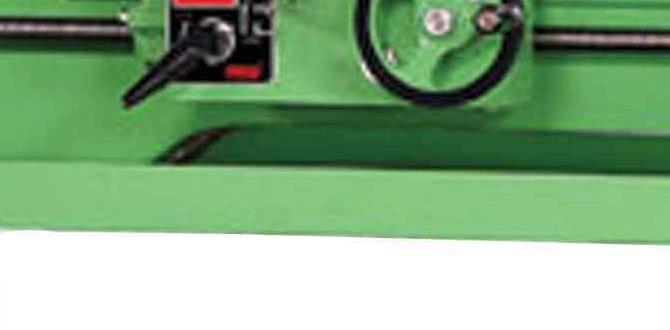

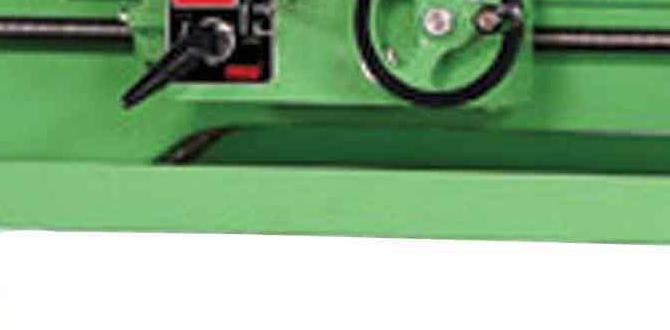

Step-by-Step Guide to Repairing Your Lathe Lead Screw

Tools needed for lead screw replacement and repair.. Detailed repair process for lead screws..To repair your lathe lead screw, you first need a few tools. Grab a wrench, some screwdrivers, and a measuring tape to start. Think of it as playing with giant toys—except these toys don’t fit in a toy box!

Next, follow these steps for a smooth repair. First, turn off the lathe and unplug it. This is a must! Then, carefully remove the lead screw. Clean any grime that might be hanging on like a bad guest at a party. After that, replace the old parts with the new ones from your lathe repair kit. Finally, reassemble everything and give it a test spin. If it goes ‘vroom’ instead of ‘grrr’, you did it right!

| Tools Needed |

|---|

| Wrench |

| Screwdrivers |

| Measuring Tape |

Remember, safety first! Always wear goggles. No one wants metal shavings in their eye—a real party pooper!

Maintenance Tips for Longevity of Lead Screws

Regular maintenance practices to extend lead screw life.. Best lubricants and techniques for maintaining lead screws..Taking care of your lead screws is like giving them a spa day—minus the cucumber slices! To keep them running smoothly, perform regular maintenance. Wipe down dust and debris to avoid wear. Use lubricants specifically meant for metal; they’re the spa treatments your screws need. Good oils can lower friction and extend life. Remember, a happy lead screw is a long-lasting lead screw!

| Lubricant | Best For |

|---|---|

| Machine Oil | General lubrication |

| Grease | Heavy-duty jobs |

| Silicone Spray | Light lubrication |

Treat those lead screws well, and they’ll be your best buddy in the workshop!

Where to Buy Quality Lathe Repair Kits

Recommended retailers and online stores.. Tips for ensuring quality and authenticity when purchasing..Looking for a great quality lathe repair kit? Many places sell them! Local hardware stores often have what you need. Shopping online can be even better. Websites like Amazon and specialized tool sites are fantastic options. They might just have the lathe repair kit metal lathe lead screw you’re after.

Before buying, check reviews! They can help spot the real deals from the fakes. Ensure the seller has a good rating and return policy—because nobody likes surprise gifts that don’t fit! Think of it like looking for a good pizza. The key is to avoid toppings (or sellers) that don’t belong!

| Retailer | Online Store | Tips for Quality |

|---|---|---|

| Local Hardware Store | Amazon | Read reviews! |

| Home Depot | ToolNut | Check return policy! |

| Menards | eBay | Look for ratings! |

Cost Considerations for Lathe Repair Kits

Breakdown of repair kit prices.. Assessing the costeffectiveness of DIY repairs versus professional service..When looking for a repair kit, prices can vary. A simple lead screw repair kit may cost around $50 to $100. More complex kits can run up to $300. DIY repairs can save money, but they need skill. Hiring a professional costs more upfront but ensures proper repair. Consider your comfort level before deciding.

What is more cost-effective: DIY or professional service?

DIY repairs might seem cheaper, but they can take time. If you make a mistake, it may cost more to fix. In many cases, hiring a professional is faster and safer.

- DIY Kits: $50 – $100

- Professional Servicing: $150 – $400

- Potential Fix Costs: $50+ for mistakes

Frequently Asked Questions about Lathe Repair Kits

Common queries regarding repair kit usage.. Troubleshooting tips for new users..Got questions about lathe repair kits? You’re not alone! Many new users wonder how to use them properly. Start by checking what’s included in the kit. Look for parts like gears and seals to learn their purpose. If your lathe is acting up, it may just need a little love—like lubricating the lead screw. Here’s a quick troubleshooting guide:

| Issue | Solution |

|---|---|

| Lathe won’t turn on | Check the power supply! |

| Strange noises | Try adding some grease! |

| Lead screw stuck | Loosen the mounting brackets! |

If all else fails, don’t panic! Ask a buddy or check online for help. Remember, every expert was once a beginner!

Conclusion

In summary, a lathe repair kit for metal lathes, especially for the lead screw, is essential. It helps keep your lathe in great shape. By using this kit, you can fix common issues and improve your machine’s performance. We encourage you to explore repair kits and learn more about lathe maintenance. Happy lathing!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits For Metal Lathe Lead Screws:Lathe repair kits help fix problems with the lead screw on a metal lathe. Lead screws are important because they move the tools to cut metal. You can use these kits to replace worn-out parts. They usually include screws, nuts, and tools for fixing. A working lathe helps us make cool metal projects!

Sure! Just let me know what question you have in mind, and I’ll be happy to help.

What Are The Essential Components Included In A Lathe Repair Kit For Lead Screws?A lathe repair kit for lead screws has important parts. You need screws to hold everything together. You also get bearings to help things move smoothly. There are guides to keep the lathe straight. Finally, you’ll find oil to keep everything running well.

How Can I Determine If My Metal Lathe’S Lead Screw Needs Repair Or Replacement?To check if your metal lathe’s lead screw needs fixing, look for signs of damage. First, see if it has any bends or cracks. You can also feel if it moves smoothly or gets stuck. If it feels rough or makes unusual sounds, it might need repair. Finally, check if it can hold the right shape when you use it.

What Common Issues Can Arise With Lathe Lead Screws That A Repair Kit Can Address?Lathe lead screws can have a few common problems. They might get worn out, making it hard to cut shapes. Sometimes, they become loose, which can cause mistakes. A repair kit can help fix these issues by providing new parts and tools. This way, your lathe can work smoothly again!

Are There Specific Maintenance Tips To Prolong The Life Of A Lead Screw On A Metal Lathe?To help a lead screw last longer, keep it clean and free from dust. You should use oil to lubricate it regularly. Check for any loose parts and tighten them if needed. Lastly, avoid putting too much weight on the lathe. Taking these steps will keep everything working smoothly!

How Do I Install New Components From A Lathe Repair Kit For A Lead Screw On My Metal Lathe?First, make sure your lathe is turned off and unplugged. Next, remove the old lead screw carefully. Take out the new parts from the repair kit. Then, follow the instructions in the kit to install the new lead screw. Finally, check that everything is tight and plug in your lathe to test it.