Have you ever watched a lathe spin? It’s fascinating! But it can also be dangerous if not handled properly. That’s why using a lathe repair kit is so important. It keeps your metal lathe well-maintained and safe to use.

Imagine working on a project and suddenly something goes wrong. A loose part could lead to accidents. This is where safety comes into play. With the right kit, you can fix issues before they become big problems.

Keeping your workspace safe is just as crucial as the tools you use. Understanding lathe safety means knowing how to prevent injuries. So, how can you protect yourself and your equipment? By learning about proper maintenance and using a lathe repair kit!

Did you know that many accidents happen from worn parts? By checking your metal lathe regularly, you can avoid these scary moments. Join us as we explore how to keep your lathe safe and running smoothly!

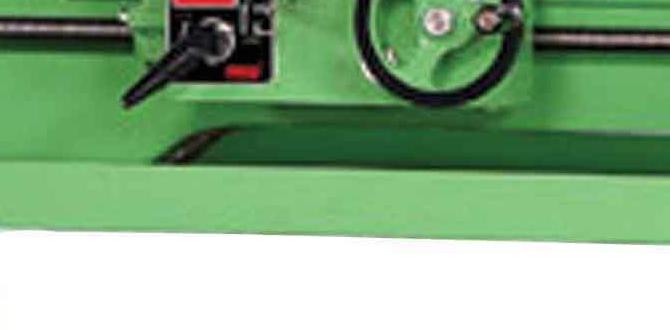

Essential Lathe Repair Kit: Metal Lathe Safety Tips

Lathe Repair Kit Metal Lathe Safety

A lathe repair kit is essential for keeping your metal lathe in top shape. Proper maintenance can prevent accidents and ensure smooth operations. Did you know that many injuries happen due to faulty equipment? Using a repair kit can help avoid these risks. Always wear safety gear, like goggles and gloves, when working. Knowing how to care for your lathe not only protects you but also extends the machine’s life. Keep your workspace tidy too; it can make a big difference in safety!Understanding Metal Lathe Safety

Importance of safety when operating a metal lathe. Common hazards associated with metal lathe usage.Using a metal lathe can be fun, but safety is super important. Picture this: spinning metal shavings flying around like confetti at a parade! Hazards include loose clothing getting caught, or tools falling. Always wear safety goggles; you don’t want bits in your eye! Also, keep your work area tidy, or you might end up with a “surprise” on the floor—nobody wants to be tripping over tools! Let’s take a look at some common hazards:

| Common Hazards | Safety Tips |

|---|---|

| Spinning Parts | Wear gloves and tie back long hair! |

| Sharp Tools | Handle with care and keep them sharp! |

| Noise | Use ear protection to shield those ears! |

Remember, a little caution goes a long way. Stay safe and happy lathe-ing!

Regular Maintenance for Safety and Longevity

Routine checks for wear and tear. Proper lubrication techniques for metal lathes.Keeping your metal lathe in top shape is like giving it a cozy blanket to keep it warm! Regular checks for wear and tear help spot problems before they become big headaches. Look at parts like belts and bearings to see if they’re feeling worn out. A little lubrication goes a long way too! Use the right oils to help your lathe run smoothly. Remember, a happy lathe equals a happy you!

| Checking Part | What to Look For |

|---|---|

| Belt | Signs of cracking or fraying |

| Bearings | Unusual noise or stiffness |

| Lubrication | Check oil levels often |

Common Issues with Metal Lathes and Their Solutions

Identifying common problems and how to resolve them. When to seek professional help versus DIY repairs.Metal lathes can act up more often than a cat in a room full of laser pointers. Common problems include vibrations, sticking tools, and uneven cuts. Each issue has a simple fix, like tightening bolts or cleaning parts. If you can’t figure it out, don’t panic! It’s wise to get help before you turn your workshop into a comedy of errors. Remember, safety first! When in doubt, a professional can save you from future head-scratching moments.

| Problem | Solution |

|---|---|

| Vibrations | Tighten bolts and check for level |

| Sticking tools | Lubricate or clean tool holders |

| Uneven cuts | Adjust tool height and speed |

Safety Precautions While Using a Lathe Repair Kit

Personal protective equipment (PPE) recommendations. Safe handling practices for tools and components.Working with a lathe repair kit can be fun and creative! However, safety is very important. Always wear personal protective equipment (PPE). This includes safety goggles to protect your eyes and earplugs to protect your hearing. Also, wear sturdy gloves and a mask to keep out dust and debris.

Here are some safe practices for handling tools:

- Always keep your workspace clean.

- Tool handles should never be damaged.

- Use the right tool for the task to avoid accidents.

- Follow instructions carefully when using equipment.

What should I wear for safety while using a lathe?

You should wear safety goggles, ear protection, gloves, and a dust mask.Step-by-Step Guide to Using a Lathe Repair Kit

Detailed instructions for common repairs. Tips for efficient use of repair tools and parts.Repairing a lathe can be easy with the right kit. Start by gathering your tools and parts. Follow these steps for common repairs:

- Check the manual for specific instructions.

- Unscrew any damaged parts carefully.

- Replace parts with new ones from your repair kit.

- Tighten everything securely.

For smooth repairs, remember:

- Organize your tools to find them fast.

- Pay attention to safety gear. Always wear goggles.

This way, you ensure lathe safety while keeping your machine running well!

What are common lathe repairs?

Common lathe repairs include fixing belts, changing bearings, and adjusting the tailstock. These repairs help keep your lathe in good working order.

Tips for safe repairs:

- Always unplug the lathe before starting.

- Store tools in a safe place.

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit. Brand recommendations and product comparisons.Picking the right lathe repair kit is important. First, think about the size of your lathe. Kits come in different sizes for different machines. Next, check what parts you need. Some kits are complete, while others only have basic tools.

Brands matter, too. Some reliable brands include:

- Grizzly

- Jet

- Harbor Freight

Looking at product reviews can help, too. Read what other users say. This will help you make a smart choice.

What should I look for in a lathe repair kit?

Focus on quality, compatibility, and ease of use. A good kit should match your machine size and include lifetime warranties.

Conclusion

In conclusion, a lathe repair kit is essential for keeping your metal lathe safe and functional. Regular maintenance helps prevent accidents. Always follow safety guidelines when using your lathe. You can read more about metal lathe care and safety to improve your skills. Let’s keep our workshops safe and effective together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits And Metal Lathe Safety:Sure! Here are answers to some questions about lathe repair kits and safety. 1. **What is a lathe repair kit?** A lathe repair kit has tools and parts to fix a lathe. It helps you keep your machine working well. 2. **Why is metal lathe safety important?** Metal lathe safety is important because it keeps you safe while working. You can avoid accidents and injuries. 3. **What should you wear when using a lathe?** You should wear safety glasses, gloves, and fitted clothes. This helps protect you from flying metal and injuries. 4. **How do you use a lathe safely?** To use a lathe safely, follow instructions. Keep your hands away from moving parts and stay focused. 5. **When should you check your lathe?** You should check your lathe before and after using it. This way, you can find problems and fix them quickly.

Sure! Please go ahead and ask your question.

What Essential Components Should Be Included In A Lathe Repair Kit For Effective Maintenance Of Metal Lathes?A lathe repair kit should have a few important tools. First, include wrenches to tighten and loosen parts. You will need screwdrivers for fixing bolts and screws. Don’t forget cleaning cloths to keep everything tidy. Lastly, some oil helps to keep the lathe running smoothly.

What Are The Recommended Safety Practices When Operating A Metal Lathe To Prevent Accidents During Repairs Or Machining?When you use a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing so nothing gets stuck. Always check that all tools are in good shape before you start. Make sure to follow the machine’s instructions carefully. If you’re unsure about something, ask for help!

How Can Users Identify Signs Of Wear Or Damage On A Metal Lathe That Would Necessitate The Use Of A Repair Kit?You can spot signs of wear or damage on a metal lathe by looking for a few things. First, check for rust or spots that look rough. Next, listen for strange noises when the machine is running. Also, see if any parts are loose or wobbling. If you notice any of these issues, you might need a repair kit.

What Types Of Protective Gear Are Advised When Working On Or Operating A Metal Lathe?When using a metal lathe, you should wear safety goggles to protect your eyes. Ear protection, like earmuffs or earplugs, is important for your hearing. You should also wear gloves to guard your hands. Finally, wear closed-toe shoes to keep your feet safe from falling tools.

How Often Should A Lathe Repair Kit Be Inspected And Replenished To Ensure Optimal Safety And Performance?You should check your lathe repair kit every few months. This helps you see if anything is broken or missing. If you notice something is used up, replace it right away. Keeping your kit full keeps you safe while working. Always be ready to fix your lathe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits And Metal Lathe Safety:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are answers to some questions about lathe repair kits and safety. 1. **What is a lathe repair kit?** A lathe repair kit has tools and parts to fix a lathe. It helps you keep your machine working well. 2. **Why is metal lathe safety important?** Metal lathe safety is important because it keeps you safe while working. You can avoid accidents and injuries. 3. **What should you wear when using a lathe?** You should wear safety glasses, gloves, and fitted clothes. This helps protect you from flying metal and injuries. 4. **How do you use a lathe safely?** To use a lathe safely, follow instructions. Keep your hands away from moving parts and stay focused. 5. **When should you check your lathe?** You should check your lathe before and after using it. This way, you can find problems and fix them quickly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question.”}},{“@type”: “Question”,”name”: “What Essential Components Should Be Included In A Lathe Repair Kit For Effective Maintenance Of Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit should have a few important tools. First, include wrenches to tighten and loosen parts. You will need screwdrivers for fixing bolts and screws. Don’t forget cleaning cloths to keep everything tidy. Lastly, some oil helps to keep the lathe running smoothly.”}},{“@type”: “Question”,”name”: “What Are The Recommended Safety Practices When Operating A Metal Lathe To Prevent Accidents During Repairs Or Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing so nothing gets stuck. Always check that all tools are in good shape before you start. Make sure to follow the machine’s instructions carefully. If you’re unsure about something, ask for help!”}},{“@type”: “Question”,”name”: “How Can Users Identify Signs Of Wear Or Damage On A Metal Lathe That Would Necessitate The Use Of A Repair Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot signs of wear or damage on a metal lathe by looking for a few things. First, check for rust or spots that look rough. Next, listen for strange noises when the machine is running. Also, see if any parts are loose or wobbling. If you notice any of these issues, you might need a repair kit.”}},{“@type”: “Question”,”name”: “What Types Of Protective Gear Are Advised When Working On Or Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should wear safety goggles to protect your eyes. Ear protection, like earmuffs or earplugs, is important for your hearing. You should also wear gloves to guard your hands. Finally, wear closed-toe shoes to keep your feet safe from falling tools.”}},{“@type”: “Question”,”name”: “How Often Should A Lathe Repair Kit Be Inspected And Replenished To Ensure Optimal Safety And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your lathe repair kit every few months. This helps you see if anything is broken or missing. If you notice something is used up, replace it right away. Keeping your kit full keeps you safe while working. Always be ready to fix your lathe!”}}]}