Have you ever wondered how a metal lathe can create perfect threads? It’s fascinating! A metal lathe is a powerful tool used in many workshops. But what happens when it breaks or needs a tune-up? That’s where a lathe repair kit comes in!

Using a lathe repair kit for thread cutting is not just smart; it’s essential. Imagine having the right tools all in one place! With a repair kit, you can fix small issues before they become big problems.

Many people don’t realize how much a lathe can do. It can shape, cut, and even create complex designs. But without a good repair kit, your lathe’s potential may go to waste.

In this article, we’ll explore everything you need to know about lathe repair kits. You’ll discover tips for maintaining your metal lathe and how to make thread cutting a breeze. Are you ready to dive in and keep your lathe running smoothly? Let’s get started!

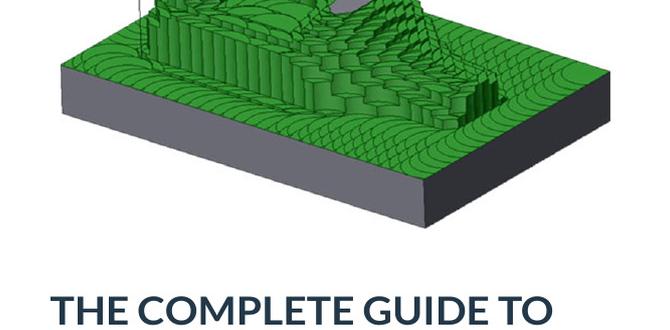

Essential Lathe Repair Kit For Metal Lathe Thread Cutting

Lathe Repair Kit for Metal Lathe Thread Cutting

A lathe repair kit can bring your metal lathe back to life. Did you know that proper threading ensures accurate cuts? This kit has essential tools for fixing and maintaining your lathe. With easy-to-follow instructions, anyone can learn to use it. Imagine cutting threads flawlessly on your projects! Not only does it save money, but it also helps you master the craft of metalworking. What will you create with a perfectly running lathe?Understanding Lathe Repair Kits

Definition and purpose of lathe repair kits. Key components included in typical repair kits.Lathe repair kits are essential tools for fixing and maintaining metal lathes. They help machines work smoothly and cut threads accurately. A typical kit usually contains:

- Thread cutting tools – for precise cuts on materials.

- Wrenches – to tighten and loosen parts easily.

- Bearings – to ensure parts move well without friction.

- Seals and gaskets – to prevent leaks.

These kits save time and money, keeping machines in top shape!

What is a lathe repair kit used for?

A lathe repair kit is used to fix and maintain lathes. It helps keep tools in good condition and prevents breakdowns.

Importance of Metal Lathe Thread Cutting

Explanation of thread cutting in metal lathes. Benefits of efficient thread cutting in machining processes.Thread cutting is like giving a metal lathe a haircut, but way cooler! It shapes threads on metal pieces for screws and bolts. This process is crucial in machining, making sure parts fit together snugly. Efficient thread cutting saves time and materials. Imagine finishing a project ahead of schedule—talk about a win! Plus, it ensures strong connections, helping machinery run smoothly. So, a reliable lathe repair kit is your best buddy for smooth sailing in this world of threads!

| Benefits of Efficient Thread Cutting |

|---|

| Saves Time – Finish projects quicker! |

| Reduces Waste – Use materials wisely! |

| Stronger Connections – Keep things together! |

Types of Lathe Repair Kits

Breakdown of various types of lathe repair kits available. Recommendations for specific kits based on lathe models.Lathe repair kits come in several types. Each kit fits different lathe models. Here’s a quick breakdown:

- Basic Kits: Include essential tools for minor repairs.

- Advanced Kits: Offer specialized tools for complex tasks.

- Model-Specific Kits: Designed for exact lathe models, ensuring a perfect fit.

When choosing a kit, consider your lathe’s make and model. For example, a kit for a Grizzly lathe may not suit a Jet lathe.

What should I consider when choosing a lathe repair kit?

Check your lathe model first. Match the kit to your lathe’s specific needs. Think about the repairs you plan to make. Basic kits work for small fixes, while advanced kits fit bigger jobs.

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit. Comparison of brands and their offerings.Picking the best lathe repair kit can be tricky. Consider these key points:

- Compatibility: Ensure the kit fits your specific lathe model.

- Quality: Look for durable materials that last long.

- Brand Reputation: Trust brands with good reviews.

- Price: Compare prices to find a balance between quality and cost.

Top brands offer various features. Some may have extra tools, while others focus on specific repairs. Check their listings and find what suits your needs best. A good choice ensures smooth operation and saves you time!

What should I look for in a lathe repair kit?

Consider the kit’s compatibility with your lathe, quality of materials, and user reviews. This helps ensure you choose a kit that works well and lasts a long time.

Steps to Use a Lathe Repair Kit

Detailed guide on how to use a repair kit effectively. Safety precautions to follow during repairs.Using a lathe repair kit is easy if you follow a few steps. First, check all the tools in your kit. Make sure they are clean and ready to use. Next, wear safety gear, like goggles and gloves. These will protect you from any flying debris. Then, carefully follow the instructions in your kit. Take your time to avoid mistakes.

- Read the user manual.

- Use the right tools for each job.

- Take breaks to avoid fatigue.

Lastly, always keep your workspace tidy. A neat area helps you focus. This keeps everyone safe, too!

What should I wear during lathe repairs?

Wear safety goggles and gloves to protect yourself from injuries and debris.

Why is a clear workspace important?

A tidy workspace helps you focus and lowers the risk of accidents.

Maintenance Tips for Metal Lathes

Best practices for maintaining metal lathes to prevent repairs. Schedule for regular maintenance checks.Keeping your metal lathe in good shape is important. Regular maintenance can save you time and money. Here are some best practices:

- Clean the lathe after each use.

- Check oil levels weekly.

- Tighten loose parts every month.

- Inspect belts and gears regularly.

Set a schedule for maintenance checks. Doing this helps to prevent repairs. Aim for full inspections every six months. Don’t wait for problems to appear. Catch them early for the best results!

How often should I maintain my metal lathe?

Full inspections should happen every six months. You should also check oil and clean the lathe after every use. Keeping a schedule helps keep everything running smooth.

Cost Considerations for Lathe Repair Kits

Typical prices for lathe repair kits and factors affecting cost. Longterm savings of proper maintenance versus repairs.Buying a lathe repair kit can cost between $50 and $300. Prices depend on quality and included parts. A good repair kit helps you save money over time. Regular maintenance can prevent big repairs and extend your lathe’s life. Think about cost now versus later. A small investment can avoid larger expenses down the road.

What affects the cost of lathe repair kits?

Quality of parts, brand reputation, and the kit’s complexity can change prices. Here are some key points:- Brand name can raise costs.

- More features usually mean a higher price.

- Simple kits are cheaper than advanced ones.

Expert Recommendations and Resources

Insights from industry experts on lathe repairs. Useful online resources for further learning and support.Keeping your lathe in top shape is crucial for smooth operation. Experts suggest regularly checking and maintaining your machine to avoid bigger issues. Your friendly neighborhood machinist will tell you that a good lathe repair kit can be a lifesaver. Resources like online video tutorials and forums are treasure troves. Websites such as YouTube and dedicated machining forums often share tips and tricks. Here’s a quick table with some handy links:

| Resource | Description | Link |

|---|---|---|

| YouTube | Video tutorials on lathe repair | Visit |

| Machining Forums | Expert advice and community support | Visit |

| Manufacturer Websites | Specific repair kits and guides | Visit |

So, don’t wrench your brain—check these out!

Conclusion

In summary, a lathe repair kit is essential for maintaining your metal lathe and ensuring it cuts threads accurately. You’ll find tools that fix issues and enhance performance. Regular maintenance helps you work better and safer. If you’re interested, check out more about lathe kits online. Learn how to get the most out of your tools!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits For Metal Lathes Specifically For Thread Cutting:Sure! Here are answers to five questions about lathe repair kits for metal lathes used for thread cutting. 1. **What is a lathe repair kit?** A lathe repair kit has parts to fix or replace broken pieces on a lathe. You can use it to help your lathe work better. 2. **Why do I need a lathe repair kit?** You need a lathe repair kit to keep your machine running smoothly. If something breaks, the kit helps you fix it quickly. 3. **How do I use a lathe repair kit?** To use a lathe repair kit, follow the instructions. You will find the right parts to replace what is broken. 4. **Can I fix my lathe by myself?** Yes, you can fix your lathe by yourself! If you have a repair kit and instructions, you can do it. 5. **Where can I buy a lathe repair kit?** You can buy a lathe repair kit at tool stores or online. Look for one that fits your lathe model.

Sure! Please provide the question you would like me to answer.

What Essential Components Should Be Included In A Lathe Repair Kit Specifically Designed For Thread Cutting Applications?A lathe repair kit for cutting threads should have some important tools. You need a set of sharp cutting tools to shape the threads. A good ruler will help you measure things accurately. Don’t forget replacement belts for moving parts that can wear out. You should also have oil to keep everything running smoothly.

How Can A Lathe Repair Kit Help Improve The Precision And Accuracy Of Thread Cutting On A Metal Lathe?A lathe repair kit helps you fix any broken parts on the metal lathe. When everything works well, it cuts threads more accurately. This means the threads will fit together better. Better fitting makes your projects stronger and more precise. So, using the kit means your lathe will do a great job!

What Common Issues Related To Thread Cutting Can Be Resolved With A Well-Equipped Lathe Repair Kit?A good lathe repair kit helps fix problems with thread cutting. You can replace worn-out parts like cutting tools. It can help adjust the machine if it is not cutting straight. You can fix the alignment to make sure threads fit better. Having these tools means you can work faster and make better threads!

How Do The Specifications Of A Lathe Repair Kit Vary Between Different Brands And Models Of Metal Lathes?The specifications of a lathe repair kit can change based on the brand and model. Each lathe is different, so the parts you need may not be the same. Some kits may have special tools or replacements that fit only certain lathes. It’s important to check what your lathe needs before buying a repair kit. This way, you can be sure you get the right parts for your machine.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Effectiveness Of A Lathe Repair Kit Used For Thread Cutting?To keep your lathe repair kit in good shape, check it often for rust or damage. Clean the tools after each use to remove dirt and metal shavings. Store them in a dry place to prevent moisture. Sharpen the cutting tools when they get dull so they work well. Finally, make sure to follow any specific instructions that come with your kit.