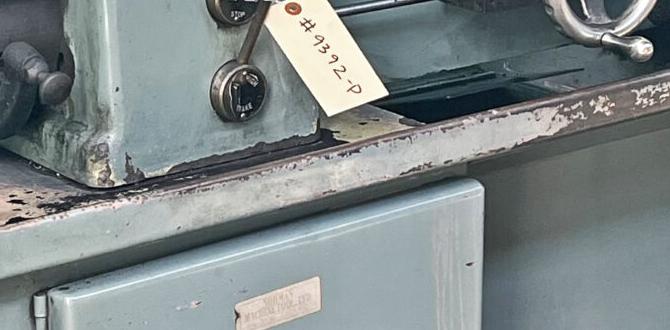

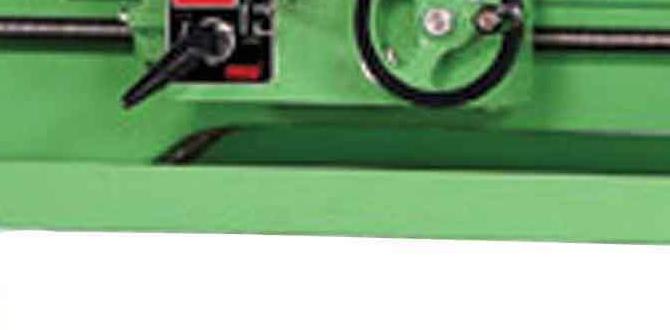

Have you ever wondered how metal lathes work? These machines are amazing tools for shaping metal. But what happens when something goes wrong? You might need a lathe repair kit to get things back on track.

Using a lathe can be fun and rewarding, but it can also be tricky. Imagine trying to create a perfect piece, but your machine won’t start. That’s where understanding a metal lathe wiring diagram comes in handy. With the right information, you can troubleshoot problems and fix them yourself.

Did you know that even small changes can make a big difference in your lathe’s performance? A simple repair kit might include the parts you need to bring your machine back to life. It’s like finding treasure in your garage!

In this article, we will explore how to use a lathe repair kit and understand the wiring diagram. You’ll discover that with a little knowledge, you can keep your metal lathe running smoothly.

Essential Lathe Repair Kit: Metal Lathe Wiring Diagram Guide

Lathe Repair Kit and Wiring Diagrams

Need to fix your metal lathe? A lathe repair kit can be a lifesaver. These kits usually include essential parts like belts, gears, and bearings. Understanding the wiring diagram is equally important. It shows how to connect everything correctly. Incorrect wiring can lead to short circuits or damage. Did you know? Many hobbyists repair their lathes at home! With the right tools and knowledge, you can save time and money. Isn’t it exciting to restore machinery?Understanding Lathe Repair Kits

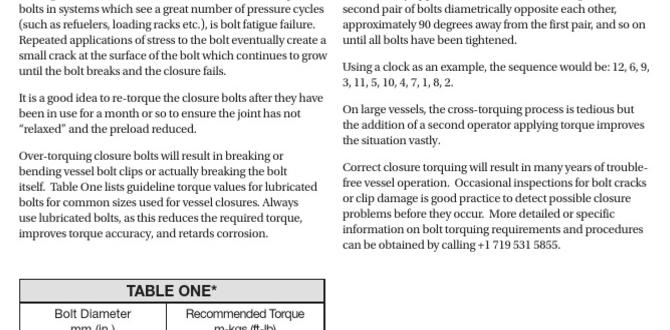

Definition and importance of lathe repair kits. Common components found in a metal lathe repair kit.Lathe repair kits are essential for keeping your metal lathe in top shape. Think of them as a superhero team for your machine. They save you from breakdowns and save you money. Inside these kits, you’ll find crucial parts like belts, bearings, and switches. Each piece plays a big role—like a band, everyone must work together to make great music!

| Component | Purpose |

|---|---|

| Belts | Keep the lathe running smoothly |

| Bearings | Support rotating parts |

| Switches | Control power to the lathe |

Having a lathe repair kit means you’re always ready for action. So, don’t wait for a machine meltdown; be prepared with the right tools!

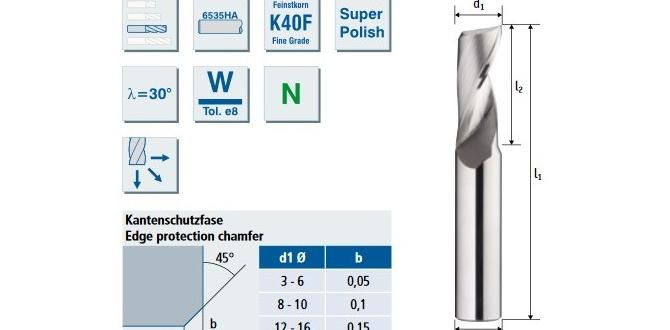

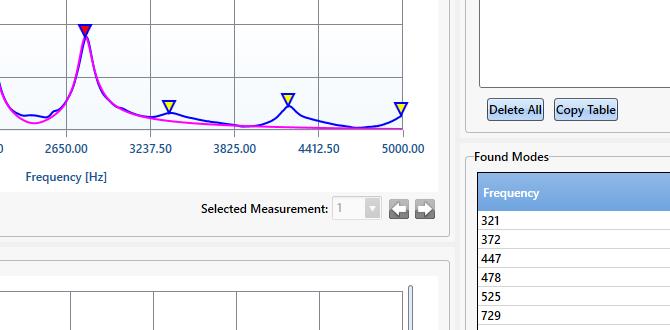

Identifying Metal Lathe Wiring Diagrams

Explanation of metal lathe wiring diagrams and their significance. How to read and interpret a wiring diagram for metal lathes.Metal lathe wiring diagrams are essential tools. They show how parts connect, ensuring your lathe runs well. Understanding them can help you fix problems quickly. To read a wiring diagram:

- Identify symbols for each part.

- Follow lines to see connections.

- Check color codes for wires.

This knowledge can save time and effort. Knowing your lathe makes repairs easy!

How can I read a metal lathe wiring diagram?

To read a wiring diagram, look for the symbols and lines connecting each part. Understanding colors can help too!

Step-by-Step Instructions for Using a Lathe Repair Kit

Detailed process for assessing the need for repairs. Guide for utilizing a repair kit effectively.Before using a lathe repair kit, check for signs of damage. Look for cracks, loose parts, or improper functioning. A careful inspection helps you know what needs fixing. Once you identify the issues, gather your repair kit. Follow these steps:

- Read the instructions carefully.

- Organize your tools and parts.

- Follow the wiring diagram for proper connections.

- Test each component after replacing it.

This process will make your repairs easier and more effective.

How do I know if my lathe needs repairs?

Check for unusual noises or vibrations while using the lathe. If parts feel loose or worn out, it’s time to inspect and possibly repair them. Regular checks help keep your machine running smoothly.Best Practices for Metal Lathe Maintenance

Routine maintenance tips for extending lathe lifespan. How proper wiring affects lathe performance.Taking care of your metal lathe is like watering a plant—it needs regular attention! To keep your lathe happy and working well, perform routine maintenance. Clean it often, check for loose parts, and keep the oil levels just right. Additionally, proper wiring is crucial. If the connections are wonky, your lathe might throw a tantrum! Remember, a well-maintained lathe can last for years, saving you money and headaches.

| Maintenance Task | Frequency |

|---|---|

| Clean the Lathe | Weekly |

| Check Wiring | Monthly |

| Oil Moving Parts | Every Use |

| Tighten Bolts | Monthly |

Choosing the Right Repair Kit for Your Metal Lathe

Factors to consider when selecting a lathe repair kit. Comparison of popular metal lathe repair kits on the market.Purchasing a lathe repair kit can be tricky. You need to consider certain factors to make the right choice. First, think about the quality of the materials. Good kits last longer. Next, check the compatibility with your specific lathe model. Finally, look for customer reviews to ensure you buy a trusted product. Some popular kits include:

- Vendor A’s Kit – Known for durability and support.

- Vendor B’s Kit – Affordable option with essential tools.

- Vendor C’s Kit – Best for specific models with extra features.

What should you look for in a lathe repair kit?

Check quality, compatibility, and reviews to ensure you make a smart choice.DIY Wiring Diagrams for Common Metal Lathe Models

Sample wiring diagrams for popular metal lathe brands. Customizing wiring diagrams for specific lathe modifications.Many popular metal lathe brands have wiring diagrams available. These diagrams help users understand how to connect the wires properly. You can find diagrams for brands like Jet, Grizzly, and South Bend. Each diagram may look different because of specific features.

Want to customize your lathe? You can change these diagrams to fit your needs. Here are tips for modifying wiring:

- Identify wire colors and jobs.

- Note extra motors or switches.

- Test changes safely.

What are common wiring diagrams for popular metal lathe brands?

Common wires include motor connections and power supply links. Each brand often has its own layout, so checking a manufacturer’s guide is essential.

How to customize wiring diagrams for specific lathe modifications?

Understand your lathe’s features before making changes. This ensures safe and efficient operation. As you modify, ensure all connections match the new setup.

Professional Help vs. DIY Repairs

Advantages of professional repair services. When to consider DIY repairs and potential pitfalls.Choosing between professional help and DIY repairs is important. Professional services offer many benefits. They have experience and the right tools. They can fix problems faster and ensure quality. Consider DIY repairs when you have small issues and feel confident. But beware! Mistakes can happen and may cost more later. Always weigh the risk.

- Advantages of Professional Repair Services: They save time.

- They fix things correctly.

- They provide warranties or guarantees.

- When to Consider DIY Repairs: You understand the problem.

- You have basic tools and skills.

- You want to learn something new.

What are the benefits of hiring a repair professional?

Hiring a professional can save you time, ensure quality work, and avoid costly mistakes. They know how to handle problems safely and effectively.

Key Points

- Cost-effective in the long run

- Access to expert advice

- Professional results

Customer Reviews and Testimonials

Importance of customer feedback in choosing a repair kit. Case studies of successful repairs using kits and wiring diagrams.Customer feedback is like a treasure map for choosing the right repair kit. It shows us which kits work and which ones are, well, not so great. For example, one happy customer saved their metal lathe using a wiring diagram that came with their kit. This kind of story can help others avoid long repair headaches. Here’s a quick look at some reviews:

| Customer | Repair Kit Used | Outcome |

|---|---|---|

| John D. | Toolkit A | Lathe fixed and running! |

| Emily R. | Toolkit B | Wiring diagram worked wonders! |

| Mike S. | Toolkit C | Stuck again, but the kit was fun! |

Learning from others helps everyone make better choices. Remember, happy customers often mean fewer headaches for you!

Conclusion

In conclusion, a lathe repair kit is essential for keeping your metal lathe running smoothly. Understanding the wiring diagram helps you fix electrical issues easily. Remember to follow instructions carefully and check each component. If you’re interested, explore more resources or guides to enhance your skills. You can tackle lathe repairs with confidence!FAQs

What Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?A lathe repair kit for metal lathes usually has several important parts. You will find tools like wrenches and screwdrivers. There are also belts that help the lathe run smoothly. You might see some oil for keeping things lubricated. Lastly, it often includes replacement parts like bearings or gears.

How Can I Interpret The Wiring Diagram For My Metal Lathe To Troubleshoot Electrical Issues?To read the wiring diagram for your metal lathe, start by finding the main parts. Look for the power supply, switches, and motors. Each line shows wires connecting these parts. You can trace the lines to see how electricity flows. If something isn’t working, check where the connection is broken or not working.

What Steps Should I Follow To Safely Replace Wiring In A Metal Lathe Using A Repair Kit?First, unplug the metal lathe so it can’t turn on. Next, wear safety gear like gloves and goggles to protect yourself. Open the lathe’s cover and carefully take out the old wires. Use the repair kit to connect the new wires, following the instructions. Finally, close the cover and plug the lathe back in to test it.

Are There Any Specific Safety Precautions To Consider When Working With The Electrical Components Of A Metal Lathe?Yes, there are safety precautions to follow when using a metal lathe. First, always make sure the machine is turned off before touching any wires. You should wear rubber gloves to protect yourself from electricity. Keep your hands dry and stay away from water while working. Finally, ask a grown-up for help if you’re unsure about anything.

Where Can I Find Reliable Wiring Diagrams For Various Models Of Metal Lathes?You can find reliable wiring diagrams for metal lathes online. Search websites like manufacturer sites or forums. YouTube can have helpful videos as well. Ask in groups where other people share their tips. That way, you can learn and get the diagrams you need.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for metal lathes usually has several important parts. You will find tools like wrenches and screwdrivers. There are also belts that help the lathe run smoothly. You might see some oil for keeping things lubricated. Lastly, it often includes replacement parts like bearings or gears.”}},{“@type”: “Question”,”name”: “How Can I Interpret The Wiring Diagram For My Metal Lathe To Troubleshoot Electrical Issues? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To read the wiring diagram for your metal lathe, start by finding the main parts. Look for the power supply, switches, and motors. Each line shows wires connecting these parts. You can trace the lines to see how electricity flows. If something isn’t working, check where the connection is broken or not working.”}},{“@type”: “Question”,”name”: “What Steps Should I Follow To Safely Replace Wiring In A Metal Lathe Using A Repair Kit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, unplug the metal lathe so it can’t turn on. Next, wear safety gear like gloves and goggles to protect yourself. Open the lathe’s cover and carefully take out the old wires. Use the repair kit to connect the new wires, following the instructions. Finally, close the cover and plug the lathe back in to test it.”}},{“@type”: “Question”,”name”: “Are There Any Specific Safety Precautions To Consider When Working With The Electrical Components Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are safety precautions to follow when using a metal lathe. First, always make sure the machine is turned off before touching any wires. You should wear rubber gloves to protect yourself from electricity. Keep your hands dry and stay away from water while working. Finally, ask a grown-up for help if you’re unsure about anything.”}},{“@type”: “Question”,”name”: “Where Can I Find Reliable Wiring Diagrams For Various Models Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find reliable wiring diagrams for metal lathes online. Search websites like manufacturer sites or forums. YouTube can have helpful videos as well. Ask in groups where other people share their tips. That way, you can learn and get the diagrams you need.”}}]}