Have you ever looked at an old tool and wondered if it could be brought back to life? Restoring a lathe can be an exciting project for anyone who loves machines. A metal lathe can turn raw material into art or useful objects. But, when you find a rusty old lathe sitting in a corner, it might seem hopeless.

This is where lathe restoration comes in. With some time, effort, and a few skills, you can breathe new life into that old tool. Imagine the pride of using a freshly restored metal lathe from your own bench!

Did you know that restoring a lathe can teach you a lot about how machines work? Every part you clean and repair tells a story. Plus, seeing the transformation can be thrilling! If you stick around, we’ll explore how you can turn that dusty old lathe into a shining gem in your workshop.

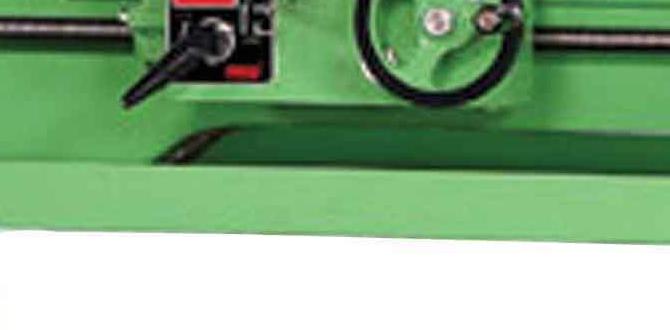

Lathe Restoration: Reviving Your Metal Lathe Bench

Lathe Restoration: Reviving Your Metal Lathe Bench

Restoring a metal lathe bench can be a fun project. It brings old tools back to life. You learn about the parts that make your lathe work best. Did you know a clean workspace can improve your results? Regular maintenance keeps the lathe running smoothly. You’ll discover tips on cleaning, lubricating, and adjusting the machine. Think of the satisfaction in transforming a rusty old lathe into a shining tool again. Imagine all the projects you could create!Understanding Lathe Restoration

Definition and importance of lathe restoration. Benefits of restoring an old metal lathe.Lathe restoration is like giving an old machine a facelift. It brings life back to tired metal lathes. This is important because a well-restored lathe can work like new, saving you money and time. Plus, it feels great to turn rusty old parts into shiny new tools! The benefits include improved efficiency, longer lifespan, and even a fun hobby for the weekend. Remember, one person’s junk is another’s masterpiece!

| Benefit | Description |

|---|---|

| Cost-Effective | Restoring a lathe is cheaper than buying a new one! |

| Skill Development | You’ll learn cool machine skills along the way. |

| Eco-Friendly | Giving new life to old machines helps the planet. |

Assessing Your Metal Lathe Bench

Key components to inspect for wear and damage. Tools and equipment needed for assessment.To check your metal lathe bench, look at key parts. Examine the bed for cracks, the tailstock for snug movement, and the cross slide for tightness. These ensure your lathe works well. Gather these tools: a wrench, a ruler, and a cleaning cloth. Each tool helps in your inspection. Regular checks can save you from bigger problems later.

What should I look for in a metal lathe bench?

Check for: wear on the bed, movement in the tailstock, and alignment of the cross slide. These are important to keep your lathe precise and functional.

- Bed: Look for cracks

- Tailstock: Test for smoothness

- Cross Slide: Ensure it moves easily

Step-by-Step Restoration Process

Disassembly: How to safely take apart your lathe. Cleaning techniques for removing rust and debris.Taking your lathe apart is like a treasure hunt! First, make sure you have a safe spot to work. Use labeled bags to keep screws and parts organized. Carefully remove each piece; we don’t want any runaway bolts! For cleaning, rust is like that stubborn stain on your favorite shirt. Use a wire brush and some vinegar—it’s almost magic! It can lift rust faster than your dog can chase its tail.

| Step | Description |

|---|---|

| Disassembly | Carefully take apart your lathe, labeling parts as you go. |

| Cleaning | Use vinegar and a wire brush to remove rust and gunk. |

Repairing and Replacing Parts

Identifying common parts that may need replacement. Sourcing replacement parts: Where to find them.Sometimes, metal lathes need a little TLC. Common parts like belts, bearings, and gears often wear out. How can you save your lathe from falling apart? Identify these parts first. Then, find replacements. You can check local hardware stores, online shops, or even vintage tool fairs. Remember, a little searching can turn your old lathe into a workhorse again. It’s like finding a missing sock, but way cooler!

| Part | Where to Find |

|---|---|

| Belts | Local hardware stores, online shops |

| Bearing | Specialty tool sites, auctions |

| Gears | Vintage tool fairs, online marketplaces |

Upgrades and Modifications

Enhancing performance with modern upgrades. Safety features to consider during restoration.Upgrading your metal lathe can make it work better. Adding modern tools boosts performance. Safety features are also important. Ensure your lathe has good guards and emergency stops. Check out these upgrades:

- New motors for power

- Improved speed controls

- Better lighting for precision

- Quality cutting tools for smoother work

These changes will keep you safe and help you work efficiently.

What safety features should I consider during lathe restoration?

Focus on features that protect you. Install safety guards and emergency shut-offs. These tools help prevent accidents while working. Check for proper shielding around sharp parts. Stay safe while you create!

Finishing Touches and Finishing Techniques

Methods for painting and finishing your restored lathe. Tips for maintaining your lathe’s appearance.After giving your lathe a makeover, it’s time for the finishing touches. Pick a paint that shines brighter than your future! Popular choices include enamel and powder coating. These not only look great but also protect your lathe from rust. To keep your beauty looking sharp, give it a quick wipe-down after use. Always keep your lathe out of direct sunlight. Sunbathing isn’t good for machines!

| Finishing Technique | Benefits |

|---|---|

| Enamel Paint | Durable and easy to apply |

| Powder Coating | Long-lasting and resistant to scratches |

Maintaining Your Restored Lathe

Regular maintenance practices for longevity. Troubleshooting common issues postrestoration.Your newly restored lathe deserves some TLC to keep spinning smoothly. Regular maintenance is key for a long life. Check the oil often to keep parts happy. Clean the chuck and check belts for wear. Replace them if they look like they’ve had a rough time—no one likes a worn-out belt!

Sometimes, things go awry even after a good fix. If your lathe suddenly stops, check the power source. It might be a simple unplugged cord. For rattles, inspect the motor and bearings. Tightening them could make everything quiet again. Remember, a well-maintained lathe is a happy lathe!

| Maintenance Task | Frequency |

|---|---|

| Check oil levels | Weekly |

| Clean chuck | Monthly |

| Inspect belts | Every 3 months |

So, keep your lathe happy and work smarter, not harder! It’s a bit like watering a plant—forget it, and you’ll be left with a sad, rusty mess!

Showcasing Your Restored Metal Lathe Bench

Creating a workspace that highlights your restored lathe. Sharing your restoration journey: Tips for documentation and sharing online.Creating a workspace that shines a light on your restored lathe can be exciting! A clean, organized area lets your hard work stand out. Add some shelves or pegboards for tools. This makes everything easy to find.

Want to share your restoration journey? Here are some quick tips:

- Take Photos: Snap pictures during each step. It shows your hard work.

- Write Notes: Jot down what you’ve learned. This adds special details to your story.

- Post Online: Share on social media or forums. Other enthusiasts will love it!

Sharing your story can inspire others too. Everyone loves a good before-and-after picture!

How can I showcase my metal lathe restoration?

Focus on clean spaces, great lighting, and clear photos of your project. Engage with the community online, and share your unique journey!

Conclusion

In conclusion, restoring a metal lathe bench can be a rewarding project. You learn new skills, like cleaning and repairing. A well-maintained lathe improves your work quality and safety. Start by gathering tools and research restoration techniques online. Remember, take your time and enjoy the process. Happy restoring, and don’t forget to share your progress!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration And Metal Lathe Benches:Sure! Here are five questions about lathe restoration and metal lathe benches. 1. **What is a lathe?** A lathe is a machine that spins metal or wood. We use it to make things like toys or tools. 2. **How do you restore a lathe?** To restore a lathe, we clean it, fix any broken parts, and paint it. This makes it work like new! 3. **What is a lathe bench?** A lathe bench is a sturdy table where we place the lathe. It keeps the machine steady while we work. 4. **Why is a good bench important for a lathe?** A good bench helps us use the lathe safely and easily. It stops the lathe from moving around when we work on it. 5. **What tools do we need for lathe restoration?** We need tools like wrenches, screwdrivers, and sandpaper. These tools help us fix and clean the lathe.

Sure! Just let me know what question you want me to answer, and I’ll keep it simple and clear for you.

What Are The Essential Steps Involved In Restoring A Vintage Metal Lathe?To restore a vintage metal lathe, you start by cleaning it. Use soap and water to remove dirt and rust. Next, check all the parts like gears and belts to see if they work. If something is broken, we can fix or replace it. Finally, after everything is clean and working, you can paint it to make it look nice!

How Do I Assess The Condition Of A Used Metal Lathe Before Purchasing It For Restoration?To check a used metal lathe, start by looking for rust. Rust can be a big problem. Next, turn the knobs to see if they move smoothly. Listen for weird sounds when you turn it on. Finally, check if all the parts are there and look for any cracks.

What Materials And Tools Are Necessary For Building A Sturdy Bench To Support A Metal Lathe?To build a sturdy bench for a metal lathe, you need strong wood or metal for the frame. Use plywood or a solid top for the surface. You’ll also need screws, bolts, and a drill to put everything together. For tools, grab a saw, a measuring tape, and a level to make sure it’s even. Don’t forget safety goggles to protect your eyes!

What Are Common Issues Faced During The Restoration Of Metal Lathes, And How Can They Be Resolved?When we restore metal lathes, we often face issues like rust and broken parts. Rust can make the machine hard to use. We can fix it by cleaning the rust off and painting the metal. Broken parts might need replacements, which we can find online or at local stores. Sometimes, old machines have missing screws, but we can find new screws that fit.

How Can I Ensure That My Restored Metal Lathe Remains Accurate And Reliable For Precision Work?To keep your metal lathe accurate and reliable, you should regularly clean it. Dust and dirt can make it less precise. Check the parts for damage and tighten any loose screws. Use proper tools for your jobs, and always follow safety rules. Finally, practice using it to get better over time!