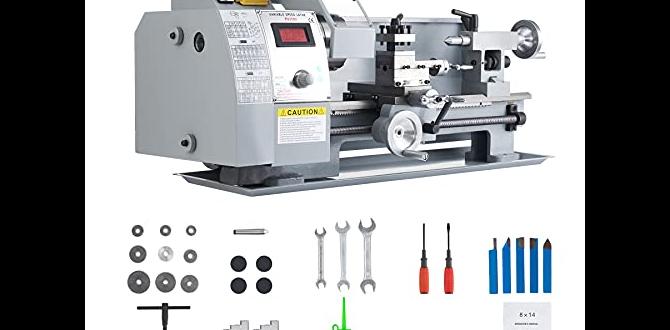

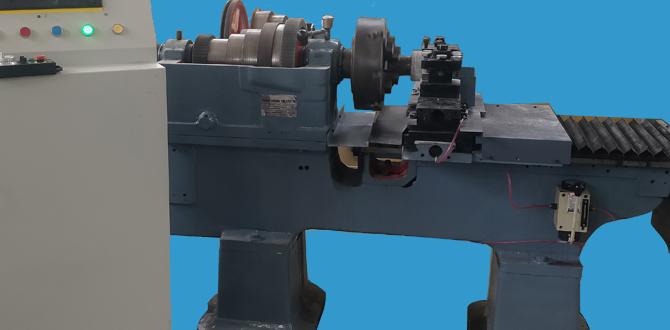

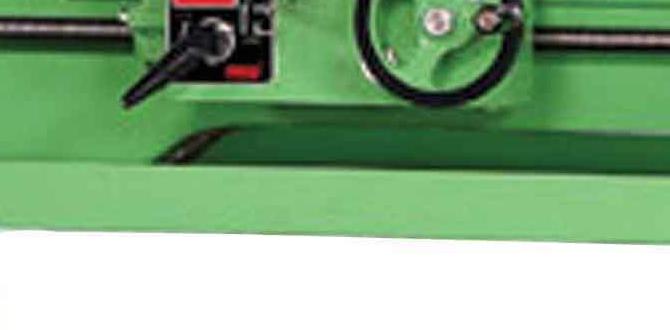

Have you ever wondered how old machines work? A lathe, for example, is a fascinating tool. It helps shape metal into amazing forms. But what happens when something goes wrong? Restoring a lathe can be a fun and rewarding project.

One important part of a lathe is the chuck key. This small tool plays a big role. It helps loosen or tighten the chuck, which holds the metal in place. Without a good chuck key, your lathe may not work as well as it could.

Imagine finding a rusty lathe in a garage. You can picture the dust and the potential hidden beneath the grime. A metal lathe, once restored, can become a source of creativity. Have you ever thought about bringing a forgotten machine back to life? Or about the satisfaction of making something shiny and new again? This article dives into the art of lathe restoration, with a focus on that little but mighty chuck key.

Lathe Restoration: The Importance Of A Metal Lathe Chuck Key

Lathe Restoration: Metal Lathe Chuck Key

Restoring a metal lathe can be an exciting project. One of the essential tools for this is the lathe chuck key. It helps secure and loosen tools with ease. Without it, working on your lathe becomes tricky. Did you know that a missing chuck key can frustrate many hobbyists? Learning to restore this tool can save you time and money. Plus, it opens up new creative opportunities in your workshop!Understanding Lathe Restoration

Definition and significance of lathe restoration. Common challenges faced during restoration.Lathe restoration is like giving your old tool a shiny makeover. It’s important because it helps keep these machines working for years. Many people find that restoring lathes can be tricky. Finding the right parts and fixing worn-out pieces can feel like hunting for a needle in a haystack. Plus, let’s face it, not every restoration goes smoothly. But with patience and a few laughs, anyone can tackle the challenges!

| Challenges | Solutions |

|---|---|

| Finding parts | Check online stores or local shops. |

| Worn-out components | Learn basic repairs and watch tutorials. |

| Time-consuming | Break tasks into smaller steps and take breaks. |

Assessing the Condition of Your Metal Lathe

Key indicators of wear and damage. How to perform a thorough inspection of the lathe.Checking your metal lathe helps keep it working well. Look for signs like rust, cracks, or worn-out parts to spot wear and damage. Use these simple steps for a good check:

- Examine the chuck key area for any wear.

- Check the bed for scratches or dents.

- Inspect gears for smooth movement.

A little care now can save you big later!

What are key wear indicators for a metal lathe?

Key signs include rust, cracks, and loose parts. These can show that your lathe needs some fixing. Regular checks ensure everything stays in shape.

Step-by-Step Guide to Restoring a Metal Lathe

Detailed restoration process from disassembly to reassembly. Techniques for cleaning and repairing key components.Restoring a metal lathe can feel like building a tiny robot! First, take your lathe apart carefully. Keep track of all the pieces, like a puzzle. Next, clean each part with soap and water. Use a toothbrush for tiny spots—it’s not just for teeth! If anything is broken, try to repair it using tape or a tiny wrench. After cleaning, put everything back together. Remember, it’s like a game of “Tetris.” If something doesn’t fit, don’t force it—be gentle!

| Step | Action |

|---|---|

| 1 | Disassemble carefully |

| 2 | Clean with soap and water |

| 3 | Repair broken parts as needed |

| 4 | Reassemble with care |

And voila! Your lathe is ready to work wonders. Just remember, restoring is more fun than fixing a broken toy, so keep it light and enjoy the process!

Focusing on the Chuck Key: Importance and Functionality

Explanation of the chuck key’s role in lathe operation. Common issues with chuck keys and their impact on performance.The chuck key is like the trusty sidekick of a lathe. It helps you tighten and loosen the chuck, which holds the workpiece in place. Without it, you might as well be trying to juggle spaghetti! Common issues with chuck keys include stripping and bending, which can ruin your projects. If the chuck key doesn’t fit right, you can end up with a loose grip. That’s like trying to hold onto a slippery banana peel. Keep it in good shape, and you’ll have a smooth ride in your metal-working adventures!

| Common Chuck Key Issues | Impact on Performance |

|---|---|

| Stripping | Can lead to an unstable grip |

| Bending | Affects tightening and loosening |

| Poor Fit | Results in wobbling workpieces |

Finding and Replacing Your Chuck Key

Tips for locating the correct replacement key. How to ensure compatibility with your lathe model.Finding the right chuck key can feel tricky, but it doesn’t have to be. First, check your lathe’s manual. It often lists the correct key type. Then, explore local hardware stores or online shops. Use the specific model name for a better search.

- Match the size: Check dimensions carefully.

- Test the fit: It should grip tightly without slipping.

- Look for quality: Strong materials ensure long-lasting use.

With these tips, you can easily locate a replacement key that works well with your lathe.

How can I find the correct chuck key?

Look at your lathe’s manual. It has details on compatible parts. You can also consult with staff at hardware stores.

Preventative Maintenance for Longevity

Best practices for maintaining your restored lathe. Routine checks and minor adjustments to enhance performance.Your restored lathe needs care to stay in great shape. Regular maintenance is key. Think of it like brushing your teeth; it keeps your tools working well. Here are some best practices:

- Check the chuck key regularly for wear.

- Clean surfaces to avoid dust buildup.

- Oil moving parts to keep them smooth.

- Inspect belts and wires for damage.

- Ensure everything is aligned properly.

By doing these simple things, you help your lathe last longer and perform better.

What is the best way to maintain a lathe?

To maintain a lathe, clean it often, check for loose parts, and oil the machine regularly. This keeps everything running smoothly and helps it last for years.

FAQs about Lathe Restoration and Chuck Keys

Common questions and expert answers. Troubleshooting tips for common problems encountered during restoration.Many people have questions about lathe restoration and chuck keys. Here are some common ones:

What is a chuck key?

A chuck key is a tool that helps you tighten or loosen the chuck on a lathe. This keeps your workpiece secure while you shape it.

How do I fix a stuck chuck?

Try gently tapping it with a hammer or using penetrating oil. Let it sit for a while, then try again.

What should I do if my lathe makes strange noises?

Check if there are any loose parts or lack of lubrication. Proper maintenance is key!

Tips for troubleshooting:

- Always keep your tools clean.

- Inspect for worn parts.

- Ensure proper lubrication regularly.

Restoring a lathe can be tricky, but knowing the basics helps. Take your time, and don’t be afraid to ask for help! It’s all part of the learning experience.

Conclusion

In conclusion, restoring a metal lathe requires care and attention to detail. The chuck key is essential for holding work pieces securely. We’ve learned that proper maintenance can extend your lathe’s life. If you need help, consider joining a DIY forum or watching restoration videos online. Keep experimenting and learning, and your lathe will work like new!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On Metal Lathe Chuck Keys:Sure! Here are five questions about lathe chuck keys. A lathe chuck key helps you tighten or loosen pieces on a lathe. You might ask why it’s important. Well, without it, we can’t hold things tightly to work properly. You might also wonder how to keep it safe. Always put it in a special place when you’re done using it!

Sure! Just let me know what question you need me to answer, and I’ll be happy to help!

What Are The Common Signs That A Chuck Key On A Metal Lathe May Need Replacement During A Restoration Project?You might need to replace a chuck key if it’s hard to turn. If the teeth are worn down or missing, that’s a sign too. Sometimes, the chuck key might not fit well anymore. If it feels loose when you use it, it’s time for a new one. Always make sure the key works well for safety!

How Can I Determine The Proper Size And Type Of Chuck Key For My Specific Metal Lathe Model?To find the right chuck key for your metal lathe, look at your lathe’s manual. The manual often tells you the size and type of key you need. You can also measure the opening of the chuck with a ruler. If you still aren’t sure, ask someone who knows about lathes for help.

What Are Some Effective Methods For Cleaning And Restoring A Rusty Or Corroded Chuck Key?To clean a rusty chuck key, you can use vinegar or lemon juice. Soak the key in it for a few hours. Then, scrub the rust off with a brush. You can also use baking soda mixed with water as a paste. After cleaning, dry it well and apply some oil to keep it from rusting again.

Are There Any Aftermarket Options Or Upgrades For Chuck Keys That Can Improve Functionality Or Ergonomics During Lathe Operation?Yes, there are better chuck keys you can buy. Some have easier grips, so they’re comfy to hold. Others come with a handle that lets you turn them more easily. You can also find ones that are magnetic, so they stick to your lathe and won’t get lost. These upgrades can make using the lathe more fun and less tiring for your hands!

What Safety Precautions Should Be Taken When Using A Chuck Key To Ensure Proper Operation And Prevent Accidents During Lathe Restoration?When using a chuck key, always keep your hands away from the spinning parts. Make sure the lathe is turned off before you start. Use the chuck key only when you need to tighten or loosen a piece. Never leave the key in the chuck because it can fly out and hurt you. Always wear safety glasses to protect your eyes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe chuck keys. A lathe chuck key helps you tighten or loosen pieces on a lathe. You might ask why it’s important. Well, without it, we can’t hold things tightly to work properly. You might also wonder how to keep it safe. Always put it in a special place when you’re done using it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you need me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That A Chuck Key On A Metal Lathe May Need Replacement During A Restoration Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to replace a chuck key if it’s hard to turn. If the teeth are worn down or missing, that’s a sign too. Sometimes, the chuck key might not fit well anymore. If it feels loose when you use it, it’s time for a new one. Always make sure the key works well for safety!”}},{“@type”: “Question”,”name”: “How Can I Determine The Proper Size And Type Of Chuck Key For My Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right chuck key for your metal lathe, look at your lathe’s manual. The manual often tells you the size and type of key you need. You can also measure the opening of the chuck with a ruler. If you still aren’t sure, ask someone who knows about lathes for help.”}},{“@type”: “Question”,”name”: “What Are Some Effective Methods For Cleaning And Restoring A Rusty Or Corroded Chuck Key?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean a rusty chuck key, you can use vinegar or lemon juice. Soak the key in it for a few hours. Then, scrub the rust off with a brush. You can also use baking soda mixed with water as a paste. After cleaning, dry it well and apply some oil to keep it from rusting again.”}},{“@type”: “Question”,”name”: “Are There Any Aftermarket Options Or Upgrades For Chuck Keys That Can Improve Functionality Or Ergonomics During Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are better chuck keys you can buy. Some have easier grips, so they’re comfy to hold. Others come with a handle that lets you turn them more easily. You can also find ones that are magnetic, so they stick to your lathe and won’t get lost. These upgrades can make using the lathe more fun and less tiring for your hands!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Chuck Key To Ensure Proper Operation And Prevent Accidents During Lathe Restoration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a chuck key, always keep your hands away from the spinning parts. Make sure the lathe is turned off before you start. Use the chuck key only when you need to tighten or loosen a piece. Never leave the key in the chuck because it can fly out and hurt you. Always wear safety glasses to protect your eyes.”}}]}