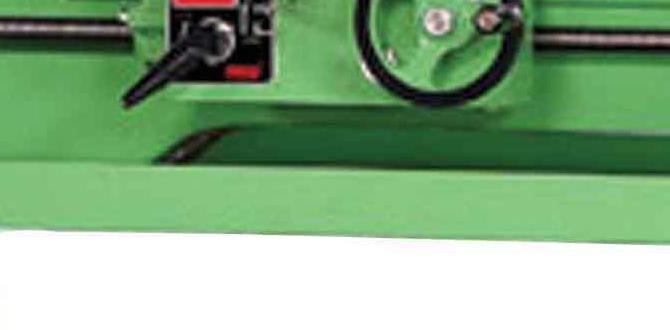

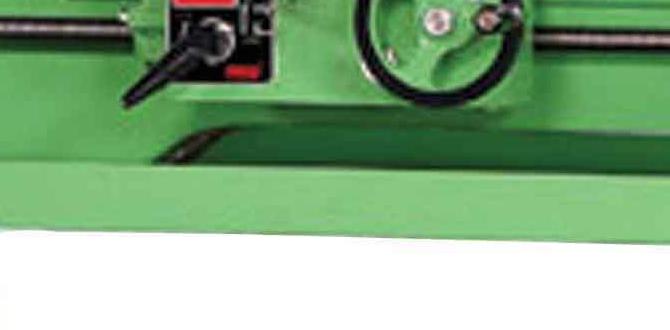

Have you ever wondered how old machines can come back to life? A lathe restoration can be an exciting journey. Imagine finding a rusty metal lathe in an old workshop. It looks forgotten, but it has so much potential! With a little care, it can turn into a masterpiece.

The key part of many lathes is the quill. This small piece plays a big role in shaping materials. Restoring the quill can seem like a challenge. You might even feel a bit scared to start. But don’t worry! Many people have successfully restored their own machines with patience and practice.

Did you know that some lathes are over a hundred years old? They have stories to tell! Each turn of the quill brings you closer to creating something amazing.

Join us as we explore lathe restoration! We will guide you through the steps of bringing an old metal lathe back to life. Are you ready to dive in?

Lathe Restoration: Reviving Your Metal Lathe Quill

Understanding the Metal Lathe Quill

Define what a metal lathe quill is and its function in lathe operations.. Discuss different types of quills and their applications in metalworking..A metal lathe quill is a key part of a lathe machine. It holds the cutting tool during metalworking tasks. This allows for precise shaping of metal parts. Different types of quills exist, including:

- Standard Quill: Used in most lathes for general tasks.

- Adjustable Quill: Enables depth changes for varied cuts.

- Heavy-Duty Quill: Built for tough materials and heavy work.

By understanding the quill, you can improve your metalworking skills.

What is the role of a metal lathe quill?

The metal lathe quill supports accurate cutting and shaping of metal. It holds the tool in place, allowing it to move smoothly during operations.

Signs Your Metal Lathe Quill Needs Restoration

Identify common issues that indicate a quill is in need of restoration.. Explain the potential impact of neglecting quill maintenance on lathe performance..Have you noticed strange sounds or vibrations while using your lathe? These signs can mean your metal lathe quill needs some attention. Here are common issues to look for:

- Rust or corrosion on the quill.

- Inconsistent movement or sticking.

- Excessive play or wobbling during operation.

- Chipped or damaged surfaces.

If you ignore these problems, your lathe might not work well. It can lead to mistakes in projects and even damage your machine. Regular maintenance keeps your lathe running smoothly.

What happens if you don’t maintain the quill?

Neglecting quill maintenance can cause poor performance, leading to lower accuracy and increased wear on parts. This can result in costly repairs or replacements.

Tools and Materials Required for Quill Restoration

List essential tools for restoring a metal lathe quill.. Provide recommendations for highquality materials needed during the restoration process..Restoring a metal lathe quill can be fun and rewarding! You’ll need some essential tools and materials to get started. Here are key items:

- Wrenches

- Screwdrivers

- Files

- Sandpaper

- A dial gauge

High-quality materials are important for a smooth restoration. Consider using:

- Oil for lubrication

- Precision bearings

- High-strength fasteners

Having the right tools makes the work easier and safer!

What tools do I need for lathe restoration?

You’ll need wrenches, screwdrivers, and files to help with your project. These tools let you loosen and tighten parts easily.

Step-by-Step Restoration Process for the Metal Lathe Quill

Detail the preparation steps before starting the restoration.. Break down each step in the restoration process with clear instructions..Before starting to restore a metal lathe quill, you need to get ready. Here are some key steps:

- Gather tools: You will need wrenches, screwdrivers, and a cleaning brush.

- Find a clean workspace: Make sure it is well-lit and organized.

- Inspect the quill: Look for rust or damage. Take notes on what needs fixing.

Next, follow these steps for restoration:

- Clean: Use a brush to remove dirt and dust.

- Repair: Fix any dents or rust found earlier.

- Reassemble: Put the quill back together safely.

Take your time, and remember, patience leads to great results!

Why is preparing important before restoration?

Preparing is crucial because it helps you understand what needs fixing. It also ensures you have the right tools and a good workspace. Doing this can make restoration easier and more successful.

Common Mistakes to Avoid During Quill Restoration

Highlight frequent errors that can occur during the restoration process.. Offer tips on how to stay on track and ensure a successful restoration..Many people jump into quill restoration without a plan. One common mistake is forgetting to clean parts before starting. Dirt can mess up everything, just like a fly in your soup! Always check your tools too. Using the wrong one can lead to frustration, or even worse—broken parts. Stay organized! Label your pieces, so you don’t end up asking, “Where did that bolt go?” Take your time, and you’ll nail it! Remember, slow and steady wins the race, even in restoration.

| Common Mistakes | Tips to Avoid Them |

|---|---|

| Not cleaning parts | Always clean before you start! |

| Using incorrect tools | Double-check your tools first. |

| Not labeling pieces | Label everything to prevent loss! |

Maintaining Your Restored Metal Lathe Quill

Provide a maintenance schedule for keeping the quill in optimal condition.. Suggest the best practices for prolonged functionality and performance..Keeping your metal lathe quill in top shape is important for great performance. Follow a simple maintenance schedule to ensure it works well:

- Clean after each use.

- Lubricate the moving parts every month.

- Check for wear and tear regularly.

- Inspect the quill for rust or stains every few weeks.

- Store it in a dry place to prevent damage.

Taking these steps will help your lathe quill last longer. Good care means better results!

How often should I maintain my metal lathe quill?

For best results, maintain your lathe quill monthly and clean it after each use.

Upgrading Your Metal Lathe Quill: Options and Considerations

Discuss potential upgrades available for quills and when they might be necessary.. Evaluate the benefits of upgrading versus restoring an existing quill..Upgrading your lathe quill can be a smart move. A new quill can improve accuracy and make your projects easier and more fun. Think about it—hunting for the right quill is less painful than hunting for a missing sock! You might need an upgrade if your quill is showing wear or affecting performance. Choosing between upgrading and restoring? Upgrading might save you time and headaches. After all, a happy lathe makes for a happy maker!

| Upgrade Option | Benefits | Considerations |

|---|---|---|

| New Quill | Improved Precision | Can be costly |

| Restoration | Cost-Effective | Time-Consuming |

Resources and Communities for Lathe Enthusiasts

List online forums, communities, and local groups for additional support and resources.. Include books, videos, and guides that can help deepen knowledge on lathe restoration..Being part of a community can make learning about lathe restoration fun and easy. Here are some great resources to explore:

- Online forums like The Home Shop Machinist and Practical Machinist

- Local groups at makerspaces or metalworking clubs near you

- Books such as “The Machinist’s Guide to Lathe Operation” and “Lathe Basics”

- Helpful videos on sites like YouTube showing tips and tricks

- Guides and blogs dedicated to lathe restoration techniques

These tools will help anyone become a lathe expert!

What online communities support lathe enthusiasts?

Many online communities exist for lathe lovers. Popular sites include Reddit, Facebook groups, and dedicated machining forums. These platforms provide advice, share projects, and offer support for beginners and experts alike.

Conclusion

In summary, restoring a metal lathe quill can be a rewarding project. You learn valuable skills and improve your tools. Focus on cleaning, inspecting, and repairing parts for better performance. We encourage you to gather resources and start your restoration journey. For more tips and techniques, check out our further reading options. Happy tinkering!FAQs

What Are The Essential Steps For Restoring The Quill Of A Metal Lathe To Ensure Optimal Performance?To restore the quill of a metal lathe, you need to follow a few steps. First, clean the quill by removing any dirt or debris. Next, inspect it for damage or wear. If you find any wear, you may need to replace it. Finally, lubricate the quill so it moves smoothly. This will help your lathe work better.

How Can I Identify Signs Of Wear Or Damage In A Lathe Quill During The Restoration Process?To check for wear or damage in a lathe quill, you can look for scratches or dents on the surface. Use your fingers to feel for rough spots; they might mean the quill is damaged. You should also check if the quill moves smoothly or if it gets stuck. Finally, look for any rust, which can show it has not been cared for properly. If you find any of these signs, the quill may need repairs.

What Tools And Materials Are Necessary For A Successful Lathe Quill Restoration Project?To restore a lathe quill, you need some important tools and materials. First, get a wrench to loosen and tighten parts. You will also need screwdrivers to remove small screws. Sandpaper helps to smooth rough surfaces. Finally, use oil to keep everything running smoothly.

How Can I Adjust The Quill After Restoration To Ensure Proper Alignment And Functionality During Machining?After restoring the quill, you should check its alignment. Use a level to see if it is straight. If it’s off, adjust the screws on the quill to fix it. Make sure it moves up and down smoothly. Test it by running a small piece of material through the machine.

Are There Any Common Pitfalls To Avoid When Restoring The Quill Of A Metal Lathe?Yes, there are some common mistakes to avoid. First, make sure you clean the quill carefully. Dirt can cause problems later. Next, don’t forget to check all the moving parts for wear and tear. If something is broken, replace it before putting everything back together. Finally, use the right tools when you work. Using the wrong tools can damage the quill.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Steps For Restoring The Quill Of A Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore the quill of a metal lathe, you need to follow a few steps. First, clean the quill by removing any dirt or debris. Next, inspect it for damage or wear. If you find any wear, you may need to replace it. Finally, lubricate the quill so it moves smoothly. This will help your lathe work better.”}},{“@type”: “Question”,”name”: “How Can I Identify Signs Of Wear Or Damage In A Lathe Quill During The Restoration Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check for wear or damage in a lathe quill, you can look for scratches or dents on the surface. Use your fingers to feel for rough spots; they might mean the quill is damaged. You should also check if the quill moves smoothly or if it gets stuck. Finally, look for any rust, which can show it has not been cared for properly. If you find any of these signs, the quill may need repairs.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Necessary For A Successful Lathe Quill Restoration Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore a lathe quill, you need some important tools and materials. First, get a wrench to loosen and tighten parts. You will also need screwdrivers to remove small screws. Sandpaper helps to smooth rough surfaces. Finally, use oil to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “How Can I Adjust The Quill After Restoration To Ensure Proper Alignment And Functionality During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “After restoring the quill, you should check its alignment. Use a level to see if it is straight. If it’s off, adjust the screws on the quill to fix it. Make sure it moves up and down smoothly. Test it by running a small piece of material through the machine.”}},{“@type”: “Question”,”name”: “Are There Any Common Pitfalls To Avoid When Restoring The Quill Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some common mistakes to avoid. First, make sure you clean the quill carefully. Dirt can cause problems later. Next, don’t forget to check all the moving parts for wear and tear. If something is broken, replace it before putting everything back together. Finally, use the right tools when you work. Using the wrong tools can damage the quill.”}}]}