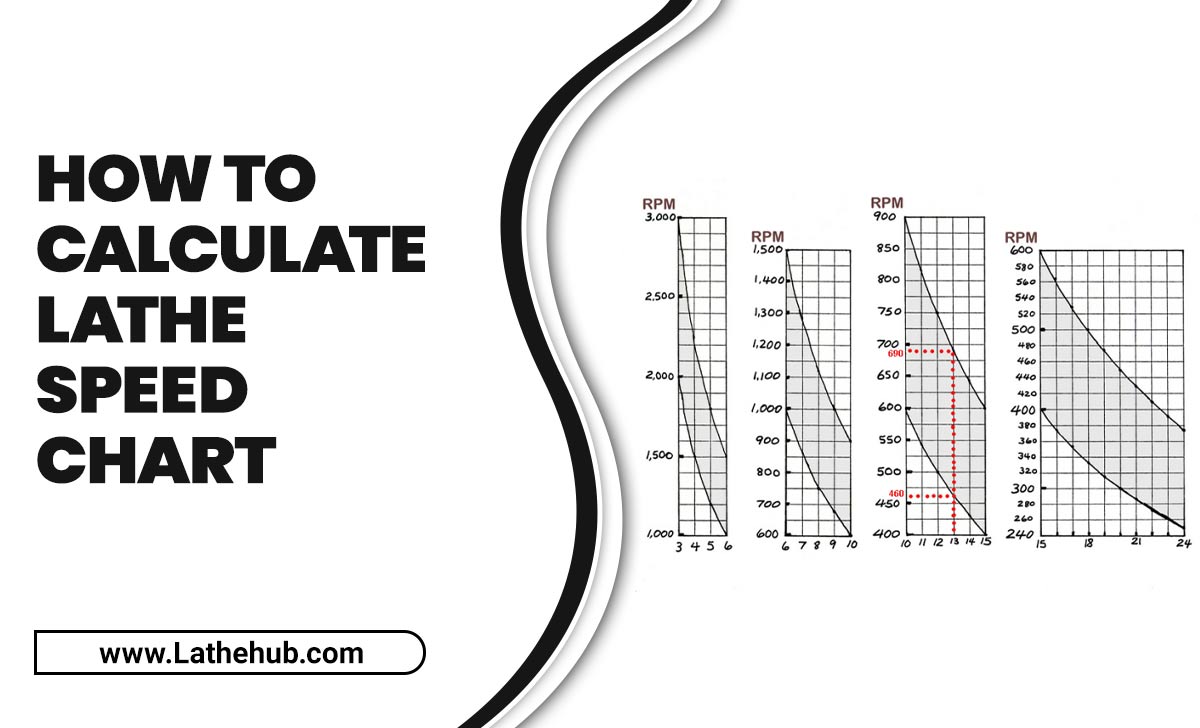

Have you ever watched a machine turn wood or metal? It’s fascinating! That magic happens on a lathe. But how do you know the right speed to turn these materials? That’s where lathe RPM and feed charts come into play.

Understanding lathe RPM is like knowing how fast to ride your bike. If you go too fast, you might crash. If you’re too slow, you might not get anywhere. The feed chart helps you find that balance. It shows how to move the tool correctly while the lathe spins.

Many people don’t know that RPM stands for revolutions per minute. It tells you how fast the lathe is spinning. Isn’t that neat? This article will explain how to read and use these charts. With this knowledge, you can create amazing projects safely and easily.

So, are you ready to dive into the world of lathe RPM and feed charts? Let’s explore together!

Lathe Rpm And Feed Chart Explained For Optimal Machining

Lathe RPM and Feed Chart Explained

When using a lathe, understanding RPM and feed rates is crucial. RPM, or revolutions per minute, affects how quickly the tool works. Choosing the right rate helps achieve better cuts and prevents damage. The feed chart guides users on how quickly to move the tool across the material. Did you know that a slower feed can lead to a smoother finish? Knowing these basics makes lathe work easier and more effective!Understanding Lathe RPM

Definition of RPM in the context of lathes. Importance of selecting the correct RPM for material types.RPM, or Revolutions Per Minute, tells us how fast the lathe spins. Think of it as the “speed limit” for your machine! Choosing the right RPM is very important because different materials need different speeds. For example, soft metals like aluminum can handle high RPMs. On the other hand, harder materials like steel require slower speeds to avoid damage. Knowing this can save your projects from turning into a big disaster.

| Material | Recommended RPM |

|---|---|

| Wood | 500-3000 |

| Aluminum | 1000-2000 |

| Steel | 200-600 |

Picking the right RPM means smoother cuts and happier projects. So, remember: spin it right, or else you might end up with a lathe tantrum!

Factors Influencing Lathe RPM

Material hardness and its impact on RPM selection. Tool geometry and its relevance to RPM.Several factors impact the speed of a lathe. First, the hardness of the material matters. Harder materials need a lower RPM to avoid tool wear. On the other hand, softer materials can handle higher speeds. Second, the shape of the cutting tools plays a vital role. For example, tools with sharp edges cut better at higher speeds. Choosing the right combination of hardness and tool shape helps achieve the best results.

How does material hardness affect lathe RPM?

Hard materials require lower RPM to reduce wear. Softer materials can work at higher speeds.

How does tool geometry influence RPM selection?

- Sharp tools work better at high speeds.

- Dull or blunt tools need lower RPM for safety.

Lathe Feed Chart Basics

Components of a feed chart and how to read it. Common units of measurement in feed charts.A feed chart is like a treasure map for those working with a lathe. It shows you how fast to move the tool. Key components include feeds per revolution and cutting speed. Reading it is simple: find your tool’s size and match it with the material. Common units are inches per minute or millimeters per minute. Remember, taking too light of a cut might make you feel like you’re tickling the metal instead of cutting it!

| Measurement | Common Units |

|---|---|

| Feed Rate | Inches per minute (IPM) |

| Cutting Speed | Surface feet per minute (SFM) |

Calculating RPM for Various Materials

Formulas for determining optimal RPM. Examples based on different materials (steel, aluminum, plastic).Understanding RPM is key for working with different materials. To find the optimal RPM, use this simple formula: RPM = (Cutting Speed x 12) / (π x Diameter). For example, for steel, you might use around 100 feet per minute (SFM), while aluminum can be much higher at 300 SFM. Plastic is even easier to handle! Here’s how it looks:

| Material | Optimal RPM |

|---|---|

| Steel | 300 |

| Aluminum | 900 |

| Plastic | 1200 |

Remember, the right RPM helps you avoid melted plastic and stubborn steel shavings flying like confetti! Keep your lathe happy and it will treat you right!

Calculating Feed Rate for Different Machining Operations

Methodologies for calculating feed rates (per revolution vs. per minute). Impact of feed rate on surface finish and tool wear.Understanding how to calculate feed rates can be a real game-changer in machining. There are two main ways: per revolution and per minute. Per revolution means you measure how far the tool moves for each full turn. Per minute counts how far the tool moves in one minute. The right feed rate can create a nice surface finish or wear out the tool faster than a speedboat in a race! Choosing wisely helps save time and money.

| Feed Rate Method | Impact |

|---|---|

| Per Revolution | Better control, but may slow down production. |

| Per Minute | Faster machining, risk of more tool wear. |

Integrating RPM and Feed Rate for Efficient Machining

Relationship between RPM and feed rate in the context of machining. Tips for optimizing both RPM and feed rate for improved production efficiency.Understanding how RPM and feed rate work together can help you make the most of your machining projects. Think of the RPM as the speed at which your lathe spins. Meanwhile, the feed rate is how fast the tool moves through the material. If you crank the RPM too high without adjusting the feed rate, you might end up with a lot of noise but not much progress. It’s like trying to eat a pizza too fast—you just end up with a mess. To optimize production efficiency, find the sweet spot where both numbers complement each other. It’s all about balance!

| RPM | Feed Rate | Tip |

|---|---|---|

| Low | High | Too slow can lead to wear! |

| High | Low | Fast means less detail! |

| Balanced | Optimized | The magic combo! |

Common Mistakes in RPM and Feed Rate Calculations

List of frequent errors when setting RPM and feed rates. Consequences of incorrect settings on machining performance.Setting the right RPM and feed rates is crucial for machining. Common errors pop up often, and they can be quite silly! One mistake is miscalculating the material type. For example, using metal settings on wood? That’s a recipe for disaster! Another goof is not adjusting for tool wear. A dull tool won’t cut like a sharp one. This can lead to poor finishes or even tool breakage, like a toothache when you eat hard candy!

| Error | Consequences |

|---|---|

| Wrong material setting | Poor machining quality |

| Neglecting tool wear | Tool breakage and poor finishes |

| Incorrect feed rates | Increased friction and heat |

Improper settings can lead to overheating, which is like frying an egg on a hot sidewalk! Always double-check your numbers to keep that machine humming smoothly.

Advanced Techniques for Setting RPM and Feed Rates

Strategies for using tooling and workpiece characteristics. Utilizing CNC systems for dynamic adjustments in RPM and feed.To improve your lathe work, consider how the tools and materials interact. Different tools need different speeds, or RPM. The material of your workpiece is also important. For example, soft metals can run at higher speeds.

CNC systems can make this easier. They adjust the RPM and feed rates on the fly. This means you get better results without many manual changes. Here are some strategies:

- Choose the right tool for the material.

- Test speeds before starting your project.

- Use CNC for real-time adjustments.

What is the importance of RPM and feed rate?

Choosing the correct RPM and feed rate helps in creating smoother and more precise cuts. It also extends tool life. This makes your work easier and saves time.

Key Points:

- Tooling matters: Use sharp, suitable tools for each job.

- Material makes a difference: Know your workpiece to set the right speed.

- CNC benefits: Automate adjustments for better results.

Case Studies: Successful Lathe Operations

Realworld examples of optimal RPM and feed rate application. Lessons learned from industry practices in lathe machining.Many factories use lathe machines, and they learn what works best from real-life examples. For instance, one company found that using a high RPM with a slower feed rate gave them the best surface finish. Another factory learned that different materials require different speeds. By studying these cases, operators can optimize their lathe setups for better results. Here are some key insights:

- Higher RPMs make smoother cuts.

- Slower feed rates help with precision.

- Different metals need different settings.

What are some real-world examples of lathe operations?

In automotive workshops, experts often set RPM between 800 to 1200 for steel parts, ensuring high accuracy and a great surface finish.Conclusion

In summary, understanding lathe RPM and feed charts is crucial for successful machining. RPM affects cutting speed, while feed rates guide how quickly we move the material. By learning these concepts, you can improve your projects. We encourage you to practice using these charts and explore more resources to enhance your skills. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Rpm And Feed Charts:Sure! A lathe is a machine that shapes metal or wood. RPM means “Revolutions Per Minute,” which tells us how fast the lathe turns. Feed charts help us choose how fast to move the tool. They are important for making sure we cut safely and get good results. Always check the chart for the right settings!

Sure! Please provide the question you want me to answer.

What Factors Should Be Considered When Determining The Optimal Rpm For A Specific Material Being Turned On A Lathe?When finding the best RPM (revolutions per minute) for a material on a lathe, you should think about the type of material. Softer materials can spin faster, while harder ones need slower speeds. You also need to consider the size of the tool you are using. The right speed helps cut smoothly and keeps the tool from wearing out too quickly. Always check the recommendations for specific materials to get the best results.

How Does The Feed Rate Affect The Surface Finish And Tool Life During A Lathe Operation?The feed rate is how fast the tool moves while cutting. If you use a slow feed rate, the surface finish can be smoother. However, if it’s too slow, it may wear out the tool faster. On the other hand, a fast feed rate can roughen the surface and make the tool last longer.

What Is The Relationship Between Spindle Speed (Rpm) And Feed Rate In Terms Of Cutting Efficiency?Spindle speed (RPM) is how fast the machine turns. Feed rate is how fast the tool moves through the material. If you turn the spindle faster, you can cut the material quicker, which boosts efficiency. But if you feed it too fast, it might not cut well. So, we need to find a good balance for the best cutting.

How Can A Machinist Use A Feed Chart To Select Appropriate Settings For Different Cutting Operations On A Lathe?A feed chart helps you pick the right settings for using a lathe, which is a machine that shapes metal. You look at the chart to find the correct feed rate, which is how fast the tool moves. The chart shows different settings based on the type of metal and the cutting job. By following the feed chart, you can make sure your cuts are smooth and safe. This makes your work easier and better!

What Are The Consequences Of Running A Lathe At Incorrect Rpms Or Feed Rates?Running a lathe at the wrong RPM (revolutions per minute) or feed rate can cause problems. You might break the tool or damage the material. It can also make the workpiece uneven or not the right shape. Plus, it can create extra heat, which is not good for the machine. Always check the settings to keep everything working well!