Have you ever wondered how a lathe works? It’s a fascinating machine that spins materials to shape them perfectly. But did you know that the lathe saddle lock plays a crucial role in its operation? Installing a lathe saddle lock might seem simple, but it’s important for safety and precision.

Imagine you’re working on a wood project. The lathe helps you turn a rough piece of wood into a smooth cylinder. But without a secure saddle lock, your work could go very wrong. The saddle lock keeps everything in place, allowing you to create beautiful shapes.

In this article, we will walk you through the steps of lathe saddle lock installation. You will learn how to do it safely and correctly. Ready to bring your lathe work to the next level? Let’s dive into the details!

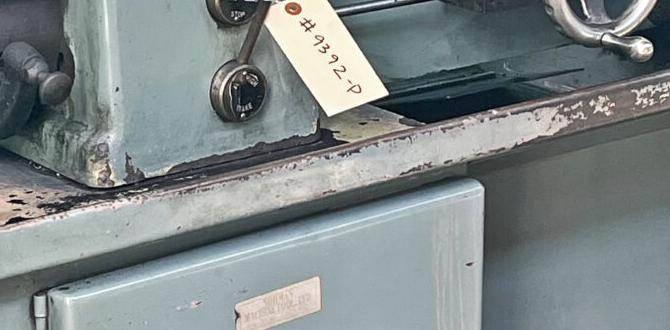

Lathe Saddle Lock Installation: A Step-By-Step Guide

Lathe Saddle Lock Installation

Installing a lathe saddle lock may sound tough, but it’s simpler than it seems. Start by gathering tools like screws and pliers. Ensure the lathe is turned off for safety. Did you know that proper installation keeps your projects precise? Align the saddle lock carefully to avoid any movement. Tighten screws firmly, but don’t overdo it! Simple mistakes can lead to big problems. By mastering this, you enhance your skills and enjoy smoother operations. Ready to lock it down?Understanding Lathe Saddle Locks

Definition and purpose of lathe saddle locks. Different types of saddle locks used in various lathes.Lathe saddle locks are crucial for keeping the lathe bed in place during work. Think of them as the seatbelt for your lathe – they keep everything secure and safe. There are several types of saddle locks, such as lever locks and worm gear locks, each suited for different lathes. Each type has its quirks, but they all aim to prevent unwanted movement, making sure your projects don’t turn into wobbly disasters!

| Type of Lock | Description |

|---|---|

| Lever Lock | Easy to operate; uses a lever for quick locking. Perfect for quick adjustments! |

| Worm Gear Lock | Offers strong stability; requires a bit more effort to tighten. |

Tools and Materials Needed for Installation

List of essential tools required for installation. Recommended materials for optimal lock installation.Installing a lathe saddle lock needs some must-have tools and materials. First, gather these essential tools:

- Wrench

- Screwdriver

- Torque wrench

- Pliers

- Measuring tape

For the best lock installation, consider using:

- High-quality screws

- Lock lubricant

- Shims

With the right tools and materials, your installation will be smooth and efficient!

What tools do I need for lathe saddle lock installation?

You need a wrench, screwdriver, torque wrench, pliers, and measuring tape. These tools make the job easier.

Safety Precautions Before Installation

Importance of safety gear and precautions during installation. Common hazards associated with lathe operation and how to avoid them.Before diving into the thrilling world of lathe saddle lock installation, let’s take a moment to gear up! Wearing safety glasses is a must, so you don’t end up with metal shavings in your eyes. Don’t forget your gloves and ear protection, especially if you plan to use noisy machines. Hazards like spinning parts and sharp tools can ruin your day or even your fingers! Always keep your workspace tidy; a clean area is a safe area. And remember, your safety gear is not a fashion statement—it’s your superhero costume!

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris |

| Gloves | Prevents cuts and abrasions |

| Ear Protection | Reduces noise damage |

Step-by-Step Guide to Installing a Lathe Saddle Lock

Detailed steps for preparing the lathe for installation. Procedure for removing the old saddle lock (if applicable). Instructions for installing the new saddle lock. Tips for ensuring proper alignment and secure fastening.Start by clearing the workspace. Ensure the lathe is turned off and unplugged for safety. Gather your tools: a screwdriver and a wrench. If there’s an old saddle lock, remove it carefully. Unscrew the bolts and take off the lock gently. Now, take the new saddle lock and line it up properly. Screw it in tight, but don’t overdo it. Check that everything is aligned. This ensures smooth operation.

What tools do I need to install a lathe saddle lock?

You will need a screwdriver and a wrench to install a lathe saddle lock.

Troubleshooting Common Installation Issues

Identification of frequent problems during installation. Solutions and tips for resolving installationrelated issues.Installing a lathe saddle lock can be tricky. Many face common problems. These can include misalignment, difficulty in tightening, or parts not fitting correctly. Here are some tips to help:

- Check for dust or debris before installation. Clean surfaces.

- Ensure all parts are compatible. Double-check sizes.

- Use the right tools. This helps avoid damaging parts.

If problems continue, consult the manual or seek help from an expert. Remember, patience pays off!

What are common problems during installation?

Misalignment and parts not fitting correctly are frequent issues. These can lead to frustration during the installation process. Taking time to troubleshoot will make your job easier.

Maintenance Tips for Lathe Saddle Locks

Routine maintenance practices for longevity of the saddle lock. Signs that indicate the need for repair or replacement.To keep your lathe saddle lock working well, you need to perform some regular checks. Clean the lock often to remove dust and grease. A clean lock is a happy lock! Look for signs of wear, like strange noises or stiffness when you turn it. If you notice these signs, it might be time for repair or even a replacement. Think of the lock like a superhero; if it starts to act funny, it may need a sidekick!

| Sign of Trouble | Action Needed |

|---|---|

| Strange noises | Check for wear |

| Stiff movement | Lubricate or replace |

| Visible damage | Consider replacement |

Enhancing the Performance of Lathe Saddle Locks

Techniques for improving lock functionality. Upgrades and accessories that can complement saddle locks.Improving the performance of lathe saddle locks can be as easy as pie… if that pie came with instructions! Start by checking the lock tightness regularly. A snug fit keeps everything secure. Upgrading to a metal lock instead of plastic can enhance durability and prevent pesky breakage.

Adding accessories like anti-slip grips also helps. These grips make turning the lock easier, especially if your hands are oily from all that pie-making! Below is a quick table of useful upgrades:

| Upgrade/Accessory | Benefit |

|---|---|

| Metal Lock | Increased durability |

| Anti-Slip Grip | Better control |

| Lock Lubricant | Smoother operation |

With these techniques, your lathe saddle locks will perform like they’re on a high-speed race track. Who knew locks could be this fun?

User Experiences and Reviews

Summary of feedback from various users on lathe saddle locks. Highlighting key points from user reviews that influence purchasing decisions.Users have shared their thoughts on lathe saddle locks, creating a lively discussion. Many found them easy to install, saving time for more important tasks—like perfecting their mustache! Reliability is a big hit among reviewers, with most saying their machines ran smoother post-installation. However, a few noted that locks sometimes came loose, prompting funny warnings like “tighten or risk a flying lathe!” Here’s a quick look at their comments:

| User Feedback | Key Points |

|---|---|

| Easy installation | Great for beginners! |

| Enhanced machine stability | Saved them from countless wobbles! |

| Occasional loosening | Tighten regularly! |

This chatter helps many new buyers decide if these locks fit their needs. It’s clear—happy users lead to happy machines! Who knew a tool could bring such joy?

FAQs about Lathe Saddle Lock Installation

Commonly asked questions regarding installation processes. Expert answers to assist users in understanding saddle lock installations.Many people have questions about installing a lathe saddle lock. Here are some common ones along with expert answers that can help. Understanding these can make the process easier and safer.

What tools do I need for installation?

You will need a wrench, screwdriver, and some screws. These basic tools will help you complete the installation easily.

Is installation difficult?

No, it’s not very hard! Follow the instructions carefully, and you can do it yourself.

How long does it take to install?

Most installations take about 30 minutes to an hour. It depends on your experience level.

Can I install it without help?

Yes, many people install it by themselves. Just make sure to follow the steps slowly.

Do I need to adjust anything after installation?

Sometimes, yes. After installation, check if the lock works smoothly and make small adjustments if needed.

Conclusion

In conclusion, installing a lathe saddle lock is important for safety and precision. First, gather your tools and instructions. Follow each step carefully to ensure proper installation. Always double-check your work before using the lathe. If you want to learn more, explore online tutorials or guides. Happy machining, and stay safe while you work!FAQs

What Are The Necessary Tools And Materials Required For Installing A Lathe Saddle Lock?To install a lathe saddle lock, you need some tools and materials. First, grab a wrench to tighten things. You’ll also need screws to hold the lock in place. A screwdriver helps to put the screws in. Lastly, check if you have the saddle lock itself, as that’s what you’re installing!

How Do You Properly Align The Saddle Lock With The Lathe Bed During Installation?To align the saddle lock with the lathe bed, first, make sure the lathe is off and safe to work on. You should carefully place the saddle on the bed. Next, look for any gaps between the saddle and the bed. Then, turn the lock until it fits tightly against the bed. Finally, check that everything moves smoothly after you lock it in place.

What Safety Precautions Should Be Taken When Installing A Lathe Saddle Lock?When you install a lathe saddle lock, make sure the machine is off. Wear safety goggles to protect your eyes. Keep your hands away from moving parts. Use tools carefully and follow instructions. If you’re unsure, ask an adult for help.

How Can You Troubleshoot Common Issues That Arise During The Installation Of A Lathe Saddle Lock?To troubleshoot common issues with a lathe saddle lock, first, check that all parts are in the box. If something doesn’t fit, look closely and see if you’re using the right screws. Sometimes, the lock may be too tight. You can loosen it a little and try again. If it still doesn’t work, ask an adult for help.

What Are The Steps To Adjust The Tension On A Newly Installed Lathe Saddle Lock For Optimal Performance?To adjust the tension on a lathe saddle lock, first, find the tension screw. You can usually see it on the saddle lock. Next, turn the screw slowly with a tool until it feels just right. Test the lock by moving it back and forth. If it’s too tight or too loose, adjust the screw again until it works well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Necessary Tools And Materials Required For Installing A Lathe Saddle Lock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a lathe saddle lock, you need some tools and materials. First, grab a wrench to tighten things. You’ll also need screws to hold the lock in place. A screwdriver helps to put the screws in. Lastly, check if you have the saddle lock itself, as that’s what you’re installing!”}},{“@type”: “Question”,”name”: “How Do You Properly Align The Saddle Lock With The Lathe Bed During Installation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the saddle lock with the lathe bed, first, make sure the lathe is off and safe to work on. You should carefully place the saddle on the bed. Next, look for any gaps between the saddle and the bed. Then, turn the lock until it fits tightly against the bed. Finally, check that everything moves smoothly after you lock it in place.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Installing A Lathe Saddle Lock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you install a lathe saddle lock, make sure the machine is off. Wear safety goggles to protect your eyes. Keep your hands away from moving parts. Use tools carefully and follow instructions. If you’re unsure, ask an adult for help.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues That Arise During The Installation Of A Lathe Saddle Lock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot common issues with a lathe saddle lock, first, check that all parts are in the box. If something doesn’t fit, look closely and see if you’re using the right screws. Sometimes, the lock may be too tight. You can loosen it a little and try again. If it still doesn’t work, ask an adult for help.”}},{“@type”: “Question”,”name”: “What Are The Steps To Adjust The Tension On A Newly Installed Lathe Saddle Lock For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tension on a lathe saddle lock, first, find the tension screw. You can usually see it on the saddle lock. Next, turn the screw slowly with a tool until it feels just right. Test the lock by moving it back and forth. If it’s too tight or too loose, adjust the screw again until it works well.”}}]}