Have you ever wondered how makers create precise threads on a lathe? The secret often lies in the lathe screw cutting dial. This handy tool helps craftsmen cut threads smoothly and accurately. But, how exactly does it work?

Imagine a scene in a workshop. A woodworker carefully adjusts his lathe. He glances at the dial, making sure every measurement is spot on. Tension fills the air as he knows that even a tiny mistake can lead to a big problem. This moment shows why proper usage of the screw cutting dial is so important.

Many people don’t realize that a small dial can lead to amazing results. With practice, anyone can master it. Ready to learn more about how to use this essential tool? Let’s dive into the world of lathe screw cutting dials and discover their wonders!

Understanding Lathe Screw Cutting Dial Usage And Its Benefits

Lathe Screw Cutting Dial Usage

Using a lathe with a screw cutting dial makes precise work easier. The dial helps you measure and cut threads accurately. You turn the dial to move the tool at a specific rate. This keeps your measurements consistent, which is crucial for making perfectly sized pieces. Did you know that ancient craftsmen used similar methods to create beautiful, intricate designs? Understanding how to use the screw cutting dial can help you unlock new possibilities in your projects!What is a Lathe Screw Cutting Dial?

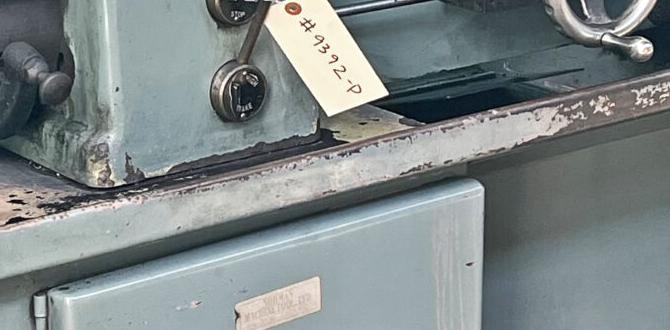

Definition and purpose of the screw cutting dial.. Different types of screw cutting dials used in lathes..A lathe screw cutting dial is a tool that helps make precise cuts on a lathe machine. It measures the distance the tool moves. It guides you to cut threads accurately. This tool is important for creating screws and bolts. There are different types of screw cutting dials:

- Manual dials: These are turned by hand for basic cuts.

- Digital dials: They show measurements on a screen for easier reading.

- Automatic dials: These can adjust the cutting distance on their own.

Using a screw cutting dial can lead to better results in your work.

What is the purpose of a screw cutting dial?

The main purpose of a screw cutting dial is to ensure precise measurements. It helps you cut threads consistently and accurately.

Key Components of a Screw Cutting Dial

Explanation of the main features and parts of the dial.. Importance of calibrating the screw cutting dial for accuracy..The screw cutting dial has several key parts that help with accuracy. The main features include a graduated scale, locking mechanism, and micro adjustment knob. Each part works together for precise measurements. Calibrating the dial is crucial. It ensures you cut screws accurately every time. If you’re off by even a tiny bit, your screw may not fit correctly.

Why is calibration important?

Calibration ensures that the measurements are accurate. Just like checking a ruler, it helps prevent mistakes. A well-calibrated dial makes using the lathe much easier and leads to better results.

- Graduated scale: Shows measurements clearly.

- Locking mechanism: Keeps settings fixed.

- Micro adjustment knob: Allows tiny tweaks for perfection.

How to Set Up the Screw Cutting Dial

Stepbystep instructions on positioning and adjusting the dial.. Tips for ensuring correct alignment with the lathe’s lead screw..To set up the screw cutting dial, follow these simple steps:

- First, turn off the lathe for safety.

- Place the dial over the lead screw.

- Align the dial so it matches the screw’s path.

- Tighten the dial securely in place.

- Double-check the alignment by rotating the dial.

For best results, keep the dial smooth and clean. This helps it move correctly. Good alignment ensures accurate cuts. Remember, the key is precise positioning!

Why is the screw cutting dial important?

The screw cutting dial helps create accurate threads. Without it, cuts may be uneven. This can damage your workpiece or waste materials.

Tips for Correct Alignment:

- Check if the dial and screw line up perfectly.

- Make small adjustments if needed.

- Test the lathe at a low speed to ensure smooth operation.

Operational Techniques for Effective Use

Best practices for utilizing the dial during screw cutting operations.. Common mistakes to avoid when using the screw cutting dial..Using the screw cutting dial on a lathe can feel tricky, but don’t worry; you’ve got this! Start by properly calibrating the dial before use. This sets the stage for success. Avoid rushing; precision is key! Make sure to take small steps, or you might end up with screws that look like spaghetti. Common mistakes? Forgetting to check dial readings often leads to mishaps. Remember, patience can save your project from a disastrous twist!

| Best Practices | Common Mistakes |

|---|---|

| Calibrate the dial correctly. | Ignoring dial readings. |

| Use a steady hand while turning. | Moving too quickly. |

| Double-check measurements. | Not practicing on scrap material. |

Maintenance and Troubleshooting of the Screw Cutting Dial

Regular maintenance tips to ensure longlasting use.. Troubleshooting common issues that may arise with the dial..Keeping your screw cutting dial in tip-top shape is easier than you think! Start with regular cleaning. Dust and shavings can sneak in and mess things up. Lubricate moving parts to keep everything running smoothly—like a well-oiled dance party! If something feels off, check the calibration. You might need a little readjustment. Here’s a quick table to help you troubleshoot common issues:

| Issue | Solution |

|---|---|

| Dial stuck | Clean and lubricate |

| Inaccurate reading | Recalibrate the dial |

| Wear and tear | Replace worn parts |

Remember, a little maintenance goes a long way! Your lathe will thank you (and maybe even throw a party).

Applications of Lathe Screw Cutting Dial in Manufacturing

Various industries that benefit from the use of screw cutting dials.. Examples of specific projects or parts produced using this method..The screw cutting dial brings big benefits to several industries. For example, in the automotive sector, workers use this tool to make precision parts like gears and bolts. It helps create items that fit together perfectly. In the aerospace industry, it’s used for manufacturing components such as engine mounts. These parts must be super precise because they fly! Here’s a quick look at some industries and items:

| Industry | Example Parts |

|---|---|

| Automotive | Gears, Bolts |

| Aerospace | Engine Mounts |

| Construction | Pipes, Fittings |

These dial tools help make sure everything runs smoothly—so no one accidentally turns a bolt into a spaghetti noodle!

Comparing Manual vs. Digital Screw Cutting Dials

Pros and cons of manual versus digital options.. Situations where one option might be preferred over the other..Both manual and digital screw cutting dials have unique advantages and disadvantages. Manual dials are often simpler and less expensive. They don’t need batteries and can work in tough conditions. However, they require more skill and practice to use correctly.

On the other hand, digital dials offer precise readings and are easier to read. But they can stop working if the battery dies. They are perfect for detailed projects but might be too complex for simple tasks.

- Manual Dials:

- Pros: Simple, cost-effective, no batteries

- Cons: Requires skill, less precise

- Digital Dials:

- Pros: Accurate, easy to read

- Cons: Battery-dependent, more complex

Choosing between them often depends on the job at hand. For quick tasks, a manual dial may work well. For detailed work, a digital dial is a better choice. This balance can make all the difference in your projects!

What are the benefits of using digital screw cutting dials?

Digital Screw Cutting Dials offer high precision, clearer readings, and easy adjustments, making them ideal for intricate projects.

Innovations and Future Trends in Screw Cutting Technology

Emerging technologies affecting the design and functionality of screw cutting dials.. Predictions for the future of screw cutting in the manufacturing industry..New technologies are changing how we do screw cutting. Smart machines and sensors help us achieve better results. Features like automatic dials make cutting easier. They save time and reduce mistakes. Here are some exciting trends:

- Use of 3D printing for making parts.

- Robots enhancing productivity.

- Advanced software for precise measurements.

These innovations will shape the future of screw cutting. The industry could grow by up to 15% by 2025, making manufacturing faster and smarter.

What are the key changes in screw cutting technology?

Key changes include smart technology, new materials, and automation. These help in making smarter machines that work better than before, improving precision and efficiency.

Conclusion

In summary, the lathe screw cutting dial helps you make precise measurements while cutting threads. It allows you to set exact distances, making your work easier and more accurate. To improve your skills, practice using the dial with different materials. You can also read more about lathe techniques to enhance your understanding. Happy turning!FAQs

What Is The Purpose Of The Screw Cutting Dial On A Lathe, And How Does It Function During The Machining Process?The screw cutting dial helps you measure and move the tool on a lathe. It makes sure the cuts are even and neat. When you turn the dial, it tells the machine how far to move. This way, you get the right size for the piece you’re making. It keeps everything precise and helps you create better shapes!

How Do You Properly Set Up And Calibrate The Screw Cutting Dial For Accurate Threading Operations On A Lathe?To set up the screw cutting dial on a lathe, first, make sure the lathe is off. Next, we need to line up the dial with the starting point of the thread. Turn the dial until the needle points to zero. Then, turn the lathe on and watch the dial as you cut. Adjust the dial if it doesn’t match the measurements, so it stays accurate.

What Are The Common Mistakes To Avoid When Using The Screw Cutting Dial To Ensure Precise Thread Dimensions?When using the screw cutting dial, avoid starting with the wrong setting. Always double-check your measurements before you cut. Keep your hands steady while moving the dial. Don’t rush; take your time to get it right. Finally, make sure you follow the right steps to avoid making mistakes.

How Can Different Pitches Of Screw Threads Be Achieved Using The Screw Cutting Dial On A Lathe?You can achieve different pitches of screw threads by using the screw cutting dial on a lathe. The dial helps you set how tightly or loosely the threads will be. You turn the dial to match the pitch you want. Pitch is the distance between each thread. By adjusting it, you can create threads that fit different screws!

What Maintenance Practices Should Be Followed To Keep The Screw Cutting Dial In Good Working Condition For Reliable Performance?To keep the screw cutting dial working well, you should clean it often. Dust and dirt can make it harder to use. You can wipe it with a soft cloth. It’s also good to check for any signs of wear or damage. If something looks broken, fix it right away. Always keep the dial properly oiled for smooth movement.