Have you ever wondered how machines stay sharp and accurate? One key part of this is lathe slideway wear testing. Lathes help shape metal and wood, but their surfaces can wear out over time. When this happens, it affects the quality of the work. Testing these slideways gives insight into how much wear there is.

Imagine trying to carve a perfect piece of wood, but your tools keep slipping. That’s frustrating, right? Regular testing can prevent such problems. It keeps machines running smoothly and saves time and money. Did you know that even small amounts of wear can lead to big issues? Discovering the right methods for lathe slideway wear testing can make all the difference.

In this article, you will learn the importance of testing and how it is done. You’ll also find out why keeping an eye on wear is crucial for machine performance. So, let’s dive into the world of lathe slideway wear testing and see what it can do for you!

Lathe Slideway Wear Testing: Importance And Methods Explained

Lathe Slideway Wear Testing

Lathe slideway wear testing helps ensure machines work well for a long time. Imagine a toy car that can’t roll because its wheels are stuck. That’s similar to what happens when slideways wear down. Tests check for smoothness, friction, and alignment. The right tools can detect problems early. Regular testing saves money on repairs and improves machine performance. By catching wear fast, you ensure precision in your work. Isn’t it fascinating how little checks lead to big results?Understanding Lathe Slideway Wear

Definition and significance of slideway wear in lathes. Common causes of wear in lathe slideways.Wear on lathe slideways is when the surfaces that help machines move start to become rough or uneven. This can cause machines to work poorly or even break. Watch for signs of wear. These surfaces are important for accurate cuts. Common reasons for wear include:

- Heavy use and pressure.

- Not enough lubrication.

- Dirty or gritty materials.

- Improper alignment of parts.

Understanding this wear helps keep machines running smooth and safe.

What are the effects of slideway wear?

Slideway wear can lead to poor machine performance, more repairs, and decreased product quality.Importance of Wear Testing

Impact of slideway wear on machining precision and equipment lifespan. Economic implications of neglected wear testing.Testing for wear on slideways is important for a few reasons. First, slideway wear can make machines less precise. If the slideway wears down, your precious projects might turn out like pancakes instead of perfect shapes. Who wants that? Second, neglecting wear testing can lead to expensive repairs and shorter equipment life. Think of it like skipping oil changes for a car; it may run fine today but will break down tomorrow!

| Impact of Neglected Wear Testing | Outcome |

|---|---|

| Reduced precision | Products may not meet specifications |

| Increased repair costs | Higher bills down the road |

| Shorter equipment lifespan | More frequent replacements needed |

Keeping an eye on wear means fewer headaches and more dollars in your pocket. Plus, who doesn’t like machines that run smoothly like butter?

Tools and Equipment for Testing Slideway Wear

Essential tools for accurate wear measurement. Comparing digital and manual measuring tools.Testing slideway wear needs the right tools. Use calipers for precise measurements. A dial gauge is great for checking small changes. Digital tools can be easier to read than manual ones. Here’s a quick comparison:

- Digital Tools: Fast and easy to read.

- Manual Tools: Cheaper and simple to use.

Choose based on your needs. The right choice helps get accurate results and keeps your lathe in good shape!

What tools are used for slideway wear testing?

The most common tools are calipers, dial gauges, and digital measuring devices. These tools help measure any wear accurately, which is vital for machine health.

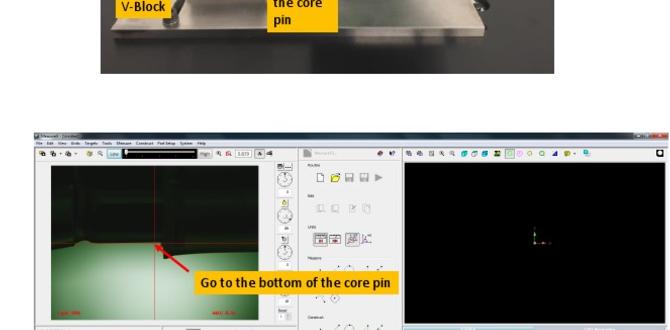

Step-by-Step Guide to Conducting Wear Testing

Preparing the lathe for wear testing. Detailed procedures for measuring slideway wear.First, make sure your lathe is clean. Dust and dirt can cause false readings. Next, check the machine’s level. A tilted lathe can fool you into thinking there’s more wear. Use a dial gauge to measure wear on the slideway. Place it at different spots to get a complete picture. After that, record your results. It’s like a treasure hunt, but instead of gold, you’re finding wear! Measurements help keep your lathe in shape!

| Step | Description |

|---|---|

| 1 | Clean the lathe thoroughly. |

| 2 | Check that the lathe is level. |

| 3 | Use a dial gauge to measure wear. |

| 4 | Record measurements at various points. |

Interpreting Wear Test Results

Understanding wear patterns and what they indicate. Guidelines for evaluating wear severity and implications.Understanding wear patterns helps us know how tools work. Light scratches may show normal use, while deep grooves suggest serious issues. Evaluating wear means looking closely at these signs. Consider these points:

- Check for shape and size of wear marks.

- Notice if wear is uneven; that can mean problems.

- Monitor how often and where wear happens.

These clues help decide if repairs are needed or if it’s time for new parts.

What do wear patterns tell us?

Wear patterns provide valuable insights into the health of machinery. Look for scratches, grooves, or discoloration to assess damage and make informed decisions.

Maintenance Practices to Mitigate Slideway Wear

Recommended lubrication techniques. Routine maintenance schedules for optimal slideway health.Keeping slideways happy is like giving your favorite toy some TLC! Lubrication is key. Applying the right oil can prevent wear and tear. Think of it as a spa day for your lathe. For best results, schedule regular maintenance. This can ensure smooth operations and long-lasting performance. A little upkeep goes a long way! Here’s a simple table to guide you on lubrication techniques and maintenance frequency:

| Lubrication Technique | Frequency |

|---|---|

| Oil Application | Daily |

| Grease Adjustment | Weekly |

| Full Inspection | Monthly |

By following these steps, you’re not just ensuring optimal slideway health; you might also impress your friends with your lathe wisdom! Who knew machinery could be so much fun?

Case Studies on Slideway Wear Testing

Analysis of successful wear testing in various industries. Lessons learned from failed wear management scenarios.Wear testing on lathe slideways has shown how different industries deal with this issue. For example, in automotive manufacturing, a successful method helped increase machine life by 25%. That’s like finding a hidden stash of candy! However, not all stories end well. A mishap in a metal processing plant taught them that ignoring wear management can cost a fortune. Remember, failing to test wear is like ignoring a sneaky tickle in your throat.

| Industry | Success Rate | Lessons Learned |

|---|---|---|

| Automotive | 25% Increase | Regular testing is key! |

| Metal Processing | Failure | Ignoring wear is costly. |

In summary, slideway wear testing can lead to remarkable improvements, but overlooking it can bring trouble. Testing is like eating your vegetables – it might not be fun, but it’s necessary for a healthy machine!

Future Trends in Lathe Slideway Wear Testing

Innovations in testing technologies. Predictions for the future of wear assessment in machining.As technology leaps forward, testing for lathe slideway wear is evolving. Innovations like real-time monitoring are on the rise. Machines could soon tell us when they’re feeling worn out, kind of like a tired dog wanting a nap! Future testing may use AI to predict wear patterns, helping to prevent problems before they happen. This means less downtime and more time making awesome things! 🌟

| Innovation | Description |

|---|---|

| Real-time Monitoring | Machines alert you when wear is detected. |

| AI Predictions | Smart systems foresee wear issues. |

These trends will keep machines running smooth, making the future of machining bright and shiny, just like our favorite superheroes! ⚙️

Resources and Further Reading

Recommended books and journals on lathe maintenance. Useful online courses and platforms for skill development.Want to dive deeper into lathe maintenance? You can check out some excellent books and journals that focus on the technical side of things. For starters, “Machine Tool Maintenance” by R. K. Gupta is a fantastic read. Online, platforms like Coursera and Udemy offer great courses to buff up your skills. Learning doesn’t have to be boring – remember, “What did the lathe say to the wrench? It’s all about the tight fit!”

| Resource Type | Title | Link |

|---|---|---|

| Book | Machine Tool Maintenance | Link |

| Online Course | Lathe Basics on Coursera | Link |

| Online Course | Lathe Training on Udemy | Link |

Conclusion

In conclusion, lathe slideway wear testing is important for maintaining machinery. It helps us identify wear and prevent costly repairs. Regular testing ensures precision in our work and extends the life of equipment. You can learn more about testing methods online or in books. Start checking your lathe regularly to keep it running smoothly!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Slideway Wear Testing:Sure! Lathe slideway wear testing checks if the sliding parts of a lathe machine are worn out. We look for scratches or rough spots. This helps us know if the lathe can still work well. If it’s too worn, we may need to fix or replace parts. Testing keeps machines running smoothly!

Sure! Please share the question you would like me to answer.

What Are The Common Methods Used To Assess Wear On Lathe Slideways, And How Do They Differ In Terms Of Accuracy And Reliability?To check wear on lathe slideways, we use a few common methods. First, we measure with a ruler or caliper for basic checks. This is simple but not always very accurate. Another method is using a dial gauge, which shows tiny differences better. Finally, we can use special tools that analyze the surface, giving us the most precise results. Each method varies in how accurately they show wear.

How Can Regular Wear Testing Of Lathe Slideways Contribute To Improved Machining Accuracy And Tool Life?Regular wear testing of lathe slideways helps us know if parts are getting worn out. By checking them often, you can fix any problems before they get worse. This means your machine works better and cuts more accurately. When the lathe works well, the tools last longer too. So, testing helps make sure everything runs smoothly!

What Specific Indicators Or Measurements Are Most Critical When Evaluating The Wear Condition Of Lathe Slideways?To check the wear on lathe slideways, you should look for some key signs. First, you can feel for rough spots when you slide things across. Next, measure any gaps between parts using a ruler. Also, watch for noise when the machine runs; it shouldn’t make bad sounds. Lastly, check for oil leaks, as they can show wear too.

How Does The Type Of Lubricant Used Impact The Wear Rate Of Lathe Slideways During Testing?The type of lubricant we use can change how much the lathe slideways wear down. Some lubricants make things slide smoothly, reducing friction. When there’s less friction, the slideways last longer. If we use a bad lubricant, it can cause more wear and tear. So, picking the right lubricant helps protect the machine!

What Maintenance Practices Can Be Implemented To Minimize Slideway Wear And Prolong The Lifespan Of A Lathe?To keep a lathe in good shape, you can do a few simple things. First, always clean the slideways to remove dirt and dust. Second, use the right oil to lubricate them, which helps them move smoothly. You should also check for any loose parts and tighten them. Finally, avoid heavy force when working on the lathe so it doesn’t wear out quickly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Slideway Wear Testing:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe slideway wear testing checks if the sliding parts of a lathe machine are worn out. We look for scratches or rough spots. This helps us know if the lathe can still work well. If it’s too worn, we may need to fix or replace parts. Testing keeps machines running smoothly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Methods Used To Assess Wear On Lathe Slideways, And How Do They Differ In Terms Of Accuracy And Reliability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check wear on lathe slideways, we use a few common methods. First, we measure with a ruler or caliper for basic checks. This is simple but not always very accurate. Another method is using a dial gauge, which shows tiny differences better. Finally, we can use special tools that analyze the surface, giving us the most precise results. Each method varies in how accurately they show wear.”}},{“@type”: “Question”,”name”: “How Can Regular Wear Testing Of Lathe Slideways Contribute To Improved Machining Accuracy And Tool Life?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular wear testing of lathe slideways helps us know if parts are getting worn out. By checking them often, you can fix any problems before they get worse. This means your machine works better and cuts more accurately. When the lathe works well, the tools last longer too. So, testing helps make sure everything runs smoothly!”}},{“@type”: “Question”,”name”: “What Specific Indicators Or Measurements Are Most Critical When Evaluating The Wear Condition Of Lathe Slideways?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the wear on lathe slideways, you should look for some key signs. First, you can feel for rough spots when you slide things across. Next, measure any gaps between parts using a ruler. Also, watch for noise when the machine runs; it shouldn’t make bad sounds. Lastly, check for oil leaks, as they can show wear too.”}},{“@type”: “Question”,”name”: “How Does The Type Of Lubricant Used Impact The Wear Rate Of Lathe Slideways During Testing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of lubricant we use can change how much the lathe slideways wear down. Some lubricants make things slide smoothly, reducing friction. When there’s less friction, the slideways last longer. If we use a bad lubricant, it can cause more wear and tear. So, picking the right lubricant helps protect the machine!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Minimize Slideway Wear And Prolong The Lifespan Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe in good shape, you can do a few simple things. First, always clean the slideways to remove dirt and dust. Second, use the right oil to lubricate them, which helps them move smoothly. You should also check for any loose parts and tighten them. Finally, avoid heavy force when working on the lathe so it doesn’t wear out quickly.”}}]}