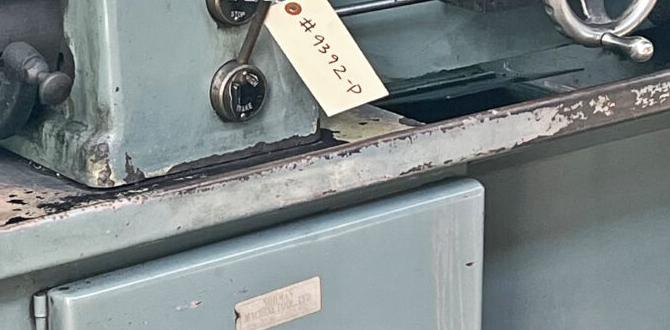

A lathe is a versatile machine tool used in various industries, such as woodworking, metalworking, and manufacturing. It is primarily handy for shaping and cutting different materials into cylindrical shapes, such as rods, shafts, and tubes.

At the heart of this machine is the lathe spindle, a crucial component that provides the necessary rotation and power to the workpiece. With the advancement of technology, the lathe spindle has evolved from a simple manual mechanism to a complex, computer-controlled system, allowing for more precise and efficient machining.

Here, we will delve into the intricacies of a lathe spindle, its function, and its various types and applications. Whether you are a beginner in the machining world or an experienced professional, understanding the fundamentals of a lathe spindle is essential for producing high-quality and accurate products.

About Lathe Spindle

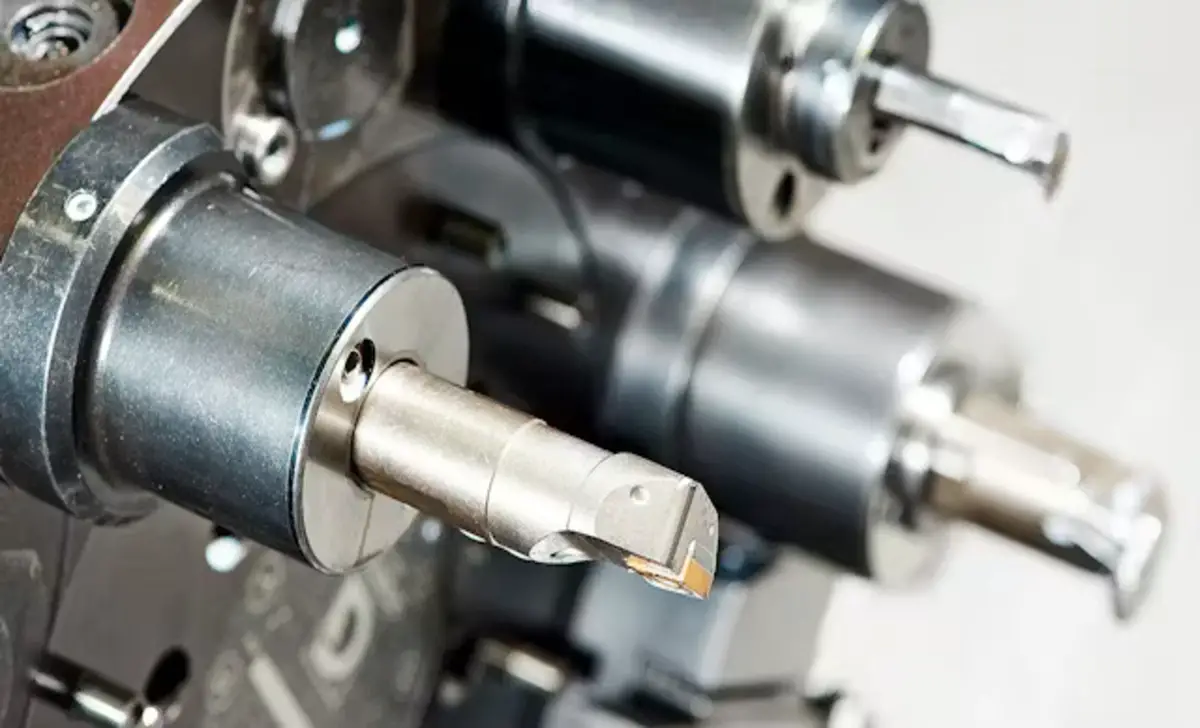

A lathe spindle is a component of a lathe machine that holds and rotates the workpiece. It has specific designs to provide the necessary power and control for various machining operations. The spindle securely holds the tooling and workpiece, allowing for precise and accurate cutting, turning, drilling, and threading processes.

Lathe spindles come in different sizes and types, depending on the specific requirements of the machining task. They typically come from high-quality materials and can operate quickly to ensure efficient and reliable performance. Overall, the lathe spindle plays a crucial role in the functioning of a lathe machine and is essential for achieving desired machining results.

5 Steps On Uses Of Lathe Spindles

There are five essential steps for efficient and accurate machining operations using lathe spindles. These steps involve mounting the workpiece, choosing the right tool, adjusting the spindle speed, performing the cutting operation, and finishing and removing the workpiece. Each step plays a significant role in machining, ensuring precision and high-quality results.

Step 1:Mounting The Workpiece

Mounting the workpiece on lathe spindles is the first step in the machining process. It involves securing the workpiece using the spindle chuck or faceplate. Proper workpiece alignment with the lathe spindle is crucial for accurate machining results. You should securely clamp the workpiece to prevent movement during machining.

The lathe bed provides a stable base for the spindle, ensuring smooth rotation and precise machining operations. Mounting the workpiece correctly ensures it remains secure and allows the desired machining operations to be performed effectively.

Step 2:Choosing The Right Tool

Selecting the appropriate cutting tool is a crucial step in the machining process. The cutting tool removes material from the workpiece and shapes it according to the desired specifications. Different cutting tools are handy for machining operations, such as turning, drilling, and milling.

The lathe machine has a tool post that holds the cutting tool, ensuring its precise positioning for efficient machining operations. The geometry and sharpness of the cutting tool are essential factors in achieving high-quality machining results.

Step 3:Adjusting The Spindle Speed

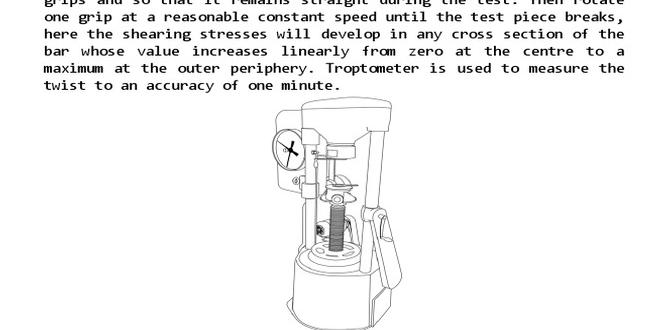

Adjusting the spindle speed based on the cutting tool’s requirements is crucial for achieving precision in machining. The spindle speed determines the rate at which the workpiece rotates, influencing the cutting speed and the quality of the machining operation.

Generally, people prefer higher spindle speeds for machining smaller workpieces, while larger workpieces may require lower speeds. The spindle speed can be adjusted using the lathe machine’s control panel, allowing the operator to optimize the machining process according to the specific requirements of the workpiece and cutting tool.

Step 4:Performing The Cutting Operation

Performing the cutting operation is the core step in the machining process utilizing the lathe spindle. The cutting tool, mounted on the lathe machine’s tool post, comes into contact with the rotating workpiece, removing material and shaping it as desired. The rotation of the lathe spindle, combined with the cutting tool’s geometry, determines the machining process and the quality of the finished product.

High-torque electric motors equip the lathe spindle to ensure efficient cutting operations in metal lathes. Additionally, the lathe spindle bearings play a crucial role in cutting, providing stability and precision during the machining operation.

Step 5:Finishing And Removing The Workpiece

After the cutting operation, the workpiece must go through the finishing process before removing it from the lathe spindle. Finishing the workpiece involves taper turning, faceplate machining, or other desired finishing operations. The lathe machine’s tailstock performs these operations, providing support and stability.

We must take care to achieve the desired precision during the finishing process. Finally, we carefully remove the workpiece from the lathe spindle, ensuring no damage or distortion. Proper carriage movement and handling of the workpiece play a vital role in the removal process, ensuring the workpiece remains intact and of high quality.

How Lathe Machines And Spindles Work

Lathe machines utilize the lathe spindle to rotate the workpiece, allowing various cutting operations. The lathe spindle, located at the headstock of the lathe machine, holds the workpiece and provides the power for the cutting tool. It is supported by precision bearings, ensuring smooth rotation and accurate machining operations.

The rotation of the lathe spindle is powered by an electric motor or belt system, providing the necessary torque to drive the cutting tool through the workpiece. You can adjust the speed and direction of rotation based on the specific requirements of the machining process. Higher spindle speed is generally handy for smaller workpieces, while lower speed is utilized for larger workpieces, allowing optimal machining results.

Different Types Of Lathe Spindles

The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining operations. It has specific designs to provide precise and controlled rotation, ensuring accuracy and efficiency in the manufacturing process. Typically, the lathe’s headstock mounts the lathe spindle, which receives power from the motor and transfers it to the workpiece. Here are Different Types of Lathe Spindles:

Direct Drive Spindle

Direct drive spindles are commonly handy in lathes for heavy-duty machining operations. These spindles are driven by high-torque electric motors, providing the power required for cutting tools to machine the workpiece.

Direct drive spindles are popular for their efficiency and effectiveness in high-volume operations, delivering the required torque and speed for machining large workpieces. These heavyweight spindles often feature camlock accessories, offering quick and secure tool changes, improving productivity, and reducing downtime.

Gear-Driven Spindle

Gear-driven spindles, commonly found in older lathes, rely on gears to transmit the power from the motor to the spindle. These spindles are popular for their robustness and reliability, capable of withstanding hefty stresses during machining operations. Gear-driven spindles are often handy in large machines requiring high power and machining capabilities, providing the cutting force and precision needed in industrial applications.

Belt-Driven Spindle

Belt-driven spindles utilize a belt to transmit power from the motor to the spindle. These spindles offer versatility in adjusting spindle speed, making them suitable for various machining needs. However, belt-driven spindles may introduce some vibration, especially at higher speeds. Smaller lathes commonly feature them, focusing on precision and the machining of smaller workpieces.

Maintenance And Care Of Lathe Spindles

The spindle plays a crucial role in determining the performance and capabilities of a lathe. It is often made from high-quality materials such as alloy or hardened tool steel to ensure durability and withstand the demanding forces involved in machining operations. The spindle is carefully machined and balanced to reduce vibrations and enhance stability, resulting in superior surface finishes and dimensional accuracy. Here are the Maintenance and Care of Lathe Spindles:

- Regularly clean the spindle to remove any dirt or debris buildup

- Lubricate the spindle bearings as per the manufacturer’s recommendations

- Check for any signs of wear or damage on the spindle and address them promptly

- Ensure proper alignment of the spindle with the lathe bed

- Use the correct tools and techniques when mounting or removing workpieces on the spindle

- Avoid overloading the spindle with excessive weight or force

- Regularly inspect and replace any worn-out or damaged parts of the spindle

Troubleshooting Common Issues With Lathe Spindles

Various lathes feature different spindle configurations to cater to specific machining needs. Some lathes have fixed spindles, while others offer the flexibility of adjustable or interchangeable spindles. Additionally, lathes may have single or multiple spindles, enabling the simultaneous machining of multiple workpieces. Here are Troubleshooting Common Issues with Lathe Spindles:

- Inspect for any visible damage or wear on the spindle components

- Check for proper alignment of the spindle with the lathe bed

- Please verify that you properly lubricate the spindle bearings

- Ensure that the spindle belt is properly tensioned and in good condition

- Verify that the spindle motor is generating sufficient power

- Check for any abnormal vibrations or noises during the operation

- Clean the spindle and remove any debris or buildup that may affect performance

Conclusion

Understanding the importance of a lathe spindle is crucial for anyone working with lathe machines. Whether you are a beginner or an experienced professional, following the proper steps and using the right tools can significantly impact the quality of your work. Additionally, choosing the right type of lathe spindle for your specific needs is essential for achieving the desired results.

Proper maintenance and care of your lathe spindle will ensure its longevity and optimal performance. Lastly, being aware of common issues and knowing how to troubleshoot them will save you time and frustration. So, remember these tips when working with lathe spindles to maximize your efficiency and productivity.

Frequently Asked Questions

1.What Is The Spindle On A Lathe?

Ans: A lathe spindle is the rotating component that holds and turns the workpiece. An electric motor or belt system drives it, allowing for adjustable speed and direction. The accuracy and stability of the spindle are crucial for precise cutting in turning operations.

2.What Is A Spindle, And What Is It Used For?

Ans: A spindle is a rotating axis that holds and rotates workpieces in machines such as lathes. The spindle rotates at high speeds and transmits power to the workpiece. Spindles come in various sizes and types, including belt-driven and direct-drive spindles. The accuracy and precision of a spindle are crucial for achieving high-quality results in machining processes.

3.What Is The Function Of The Spindle In The Machine?

Ans: The spindle is a rotating component in a machine that holds and rotates the workpiece. It provides power to the cutting tool to perform various machining operations. You can adjust the spindle’s speed based on the machining process’s requirements. The machined part’s accuracy and quality depend on the spindle’s precision and stability.

4.What Are The Different Types Of Lathe Spindles?

Ans: The most common types of lathe spindles are plain, threaded, and tapered. Plain spindles are the simplest type and do not have any special features. Threaded spindles have threads on the inside or outside, allowing for easy attachment of accessories. Tapered spindles have a taper that allows for a secure fit with accessories like chucks or faceplates.

5.What Is A CNC Lathe Spindle?

Ans: A CNC lathe spindle is a rotating component of a computer numerical control (CNC) lathe machine that holds and rotates the workpiece being machined.