Have you ever wondered how a lathe spins so smoothly? One big secret lies in something called a spindle bearing. These tiny parts play a huge role in ensuring your lathe works like magic. But what happens when they wear out?

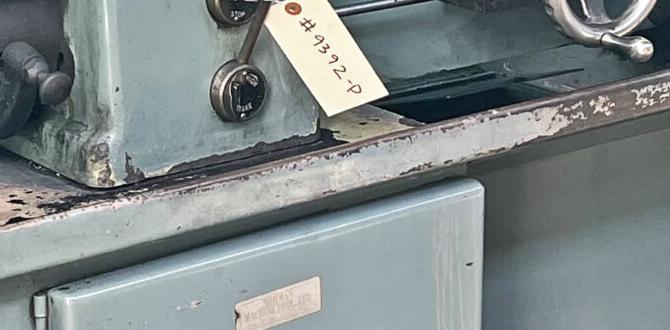

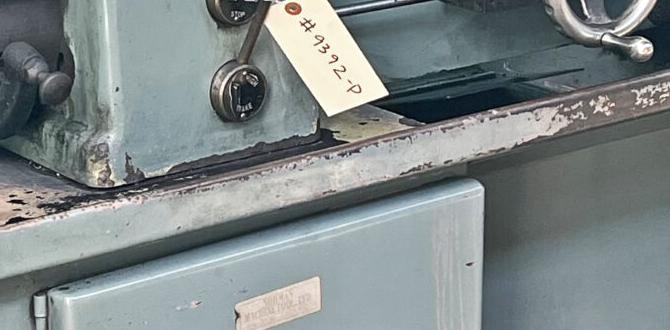

Imagine you’re in your workshop, ready to create something amazing. Suddenly, your lathe starts to make strange noises. It wobbles, and the cuts become uneven. Frustrating, right? This could mean it’s time for a lathe spindle bearing replacement.

Replacing these bearings can seem tricky, but it doesn’t have to be. By learning how to do it yourself, you can save time and money. Plus, you’ll feel proud of making your machine run better again!

In this article, we will explore the steps in replacing lathe spindle bearings. You’ll discover tips and tricks that make the job easier. Let’s dive into the world of lathe maintenance and keep that workshop humming!

Lathe Spindle Bearing Replacement: A Complete Guide

Understanding Lathe Spindle Bearing Replacement

Replacing lathe spindle bearings can extend the life of your machine. Did you know that worn-out bearings can lead to poor performance? It’s true! Noticing vibrations or unusual noises? These could be signs that it’s time for a replacement. When you replace the bearings, ensure proper alignment to maintain accuracy. Selecting the right parts is crucial. Always keep the right tools on hand to avoid frustrating delays. With careful attention, you can enhance your lathe’s efficiency and enjoy smoother operation.Understanding Lathe Spindles

Definition and function of lathe spindles. Importance of spindle bearings in lathe performance.Lathe spindles are like the heart of the lathe machine, spinning and holding tools in place. They help shape wood or metal, making them essential for any lathe work. Imagine trying to ride a bike without wheels—tough, right? That’s how crucial spindles are! The performance of a lathe really depends on spindle bearings, which reduce friction and keep everything running smoothly. If these bearings wear out, it’s like trying to run a race in flip-flops! Always check them to keep your machine happy.

| Function | Importance of Spindle Bearings |

|---|---|

| Hold cutting tools securely | Reduce friction and wear |

| Facilitate smooth rotation | Ensure precision in work |

Common Signs of Worn Spindle Bearings

Symptoms indicating the need for replacement. Consequences of ignoring spindle issues.Worn spindle bearings often show clear signs that something is wrong. Look out for unusual noises during operation. A grinding or rattling sound can mean trouble. Vibration is another big clue. If you notice your lathe shaking, it may be time to check the bearings. Ignoring these signs can lead to serious consequences, like damage to other parts or complete machine failure.

- Grinding noises

- Increased vibration

- Reduced accuracy

What are the signs of damaged spindle bearings?

Common signs include unusual noises, increased vibration, and poor performance. Addressing these issues early can save time and money.

Tools and Materials Needed for Replacement

Essential tools for spindle bearing replacement. Recommended replacement bearings and materials.To replace your lathe spindle bearing, you need some important tools and materials. First, gather these essential items:

- Wrenches

- Socket set

- Screwdrivers

- Hammer

- Plastic mallet

- Grease or oil

Make sure to choose quality replacement bearings for better performance. Look for trusted brands that suit your lathe type. High-quality materials make a big difference!

What tools do you need for bearing replacement?

You will need wrenches, a socket set, screwdrivers, a hammer, and grease.Recommended bearing brands:

- Timken

- NSK

- FAG

Step-by-Step Guide to Replacing Lathe Spindle Bearings

Detailed procedures for disassembling the lathe. Instructions for installing new bearings.Replacing lathe spindle bearings is important for smooth operation. First, carefully disassemble the lathe. Remove any covers and unscrew the parts holding the spindle. Handle everything gently to avoid damage. Next, take out the old bearings. Clean the spindle area thoroughly. Then, it’s time to install the new bearings. Place them in their spots and secure everything back in place. Make sure nothing is loose. Finally, check the operation to ensure everything runs smoothly.

How do you disassemble a lathe for bearing replacement?

Start by removing any covers and unscrewing the holding parts. Then, gently take out the spindle and old bearings for better access.

Steps for Disassembly:

- Remove covers carefully.

- Unscrew holding parts.

- Take out the spindle gently.

- Extract old bearings.

Common Mistakes to Avoid During Replacement

Errors that can lead to improper installation. Tips for ensuring a successful bearing replacement.Replacing lathe spindle bearings can be tricky. Many errors can lead to poor installation. To avoid mistakes, focus on these tips:

- Always check the size of the new bearing.

- Clean the area before installation.

- Use the right tools for the job.

- Align everything correctly to prevent wobbling.

- Don’t rush; take your time for the best results.

Proper care will ensure a smooth replacement and better machine performance. Remember, even small mistakes can create big problems!

What should I check before replacing bearings?

Check for wear and tear on the spindle. Ensure the new bearing fits snugly and is free of damage.

Maintenance Tips for Longevity of Spindle Bearings

Best practices for maintaining lathe spindle bearings. Recommended schedules for inspection and lubrication.To keep your lathe spindle bearings in great shape, follow these simple tips. Regular inspections are key. Check the bearings every month for wear or damage. Lubricate them regularly to keep them running smoothly. Use good quality oil that fits your lathe’s needs.

- Inspect bearings monthly.

- Lubricate with proper oil.

- Keep the workspace clean.

Taking care of your spindle bearings can extend their life. Remember, a well-maintained lathe means better work for you!

How often should I inspect spindle bearings?

You should inspect spindle bearings monthly. Regular checks help catch small problems before they become big issues.

When to Seek Professional Help

Indicators that professional assistance may be necessary. Benefits of expert services for lathe maintenance.Sometimes, fixing your lathe spindle is tricky. You might need expert help if you notice any of these signs:

- Strange noises while using the lathe.

- Vibrations that make it hard to control.

- Visible wear or damage on parts.

Getting professional help has its perks. Experts ensure everything works right and safely. They can spot problems early, saving you from bigger repairs later. Plus, their experience helps your lathe run longer and better.

When should I consider professional assistance?

Look out for odd sounds, excessive vibrations, or visible damage on your machine. These signs mean it’s time to call an expert!

Conclusion

In summary, replacing a lathe spindle bearing can improve your machine’s performance. It’s important to choose the right parts and follow instructions carefully. Regular maintenance will help prevent future issues. If you want to learn more, check out guides and videos online. You can successfully take on this project and keep your lathe running smoothly!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Spindle Bearing Replacement:Sure! Here are five questions about replacing lathe spindle bearings: 1. What is a lathe? 2. Why do we need to replace spindle bearings? 3. How do we know when to replace them? 4. What tools do we need to replace spindle bearings? 5. Can I replace the bearings myself?

Sure! Please give me the question you would like me to answer, and I will help you.

What Are The Signs That Indicate A Lathe Spindle Bearing Needs To Be Replaced?If a lathe spindle bearing needs to be replaced, you might notice some signs. First, listen for strange noises. If you hear grinding or knocking sounds, that’s a warning. You may also see more vibrations when the lathe is running. Lastly, if the spindle feels loose or doesn’t spin smoothly, it’s time to check the bearing.

What Steps Should Be Followed For Properly Removing And Installing Bearings On A Lathe Spindle?To remove bearings from a lathe spindle, first turn off the machine and unplug it. Next, take off any covers or parts blocking the bearings. Use a special tool or hammer gently to take out the old bearings. When installing new bearings, make sure they fit perfectly and use oil for lubrication. Finally, put everything back together and test the lathe before use.

How Do I Select The Right Type Of Bearings For My Lathe Spindle Replacement?To choose the right bearings for your lathe spindle, you should first look at the size. Measure the old bearings carefully. Check the type of work you will do. Some tasks need stronger bearings. Finally, make sure to pick a good brand for quality.

What Tools Are Necessary For Replacing The Bearings In A Lathe Spindle?To replace the bearings in a lathe spindle, you need a few important tools. First, you will need a wrench to unscrew the bolts. A hammer helps to tap out the old bearings. You also need a bearing puller to grip and remove the bearings safely. Lastly, some clean cloths will help keep everything tidy.

How Can I Maintain My Lathe Spindle Bearings To Extend Their Lifespan After Replacement?To keep your lathe spindle bearings in good shape, you need to clean them regularly. Use a soft cloth to wipe off dust and dirt. Make sure to add the right amount of oil to keep them smooth. Check them often to see if they feel loose or make noise. If you notice any problems, fix them quickly to help them last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Spindle Bearing Replacement:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about replacing lathe spindle bearings: 1. What is a lathe? 2. Why do we need to replace spindle bearings? 3. How do we know when to replace them? 4. What tools do we need to replace spindle bearings? 5. Can I replace the bearings myself?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you would like me to answer, and I will help you.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Lathe Spindle Bearing Needs To Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe spindle bearing needs to be replaced, you might notice some signs. First, listen for strange noises. If you hear grinding or knocking sounds, that’s a warning. You may also see more vibrations when the lathe is running. Lastly, if the spindle feels loose or doesn’t spin smoothly, it’s time to check the bearing.”}},{“@type”: “Question”,”name”: “What Steps Should Be Followed For Properly Removing And Installing Bearings On A Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove bearings from a lathe spindle, first turn off the machine and unplug it. Next, take off any covers or parts blocking the bearings. Use a special tool or hammer gently to take out the old bearings. When installing new bearings, make sure they fit perfectly and use oil for lubrication. Finally, put everything back together and test the lathe before use.”}},{“@type”: “Question”,”name”: “How Do I Select The Right Type Of Bearings For My Lathe Spindle Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right bearings for your lathe spindle, you should first look at the size. Measure the old bearings carefully. Check the type of work you will do. Some tasks need stronger bearings. Finally, make sure to pick a good brand for quality.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Replacing The Bearings In A Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To replace the bearings in a lathe spindle, you need a few important tools. First, you will need a wrench to unscrew the bolts. A hammer helps to tap out the old bearings. You also need a bearing puller to grip and remove the bearings safely. Lastly, some clean cloths will help keep everything tidy.”}},{“@type”: “Question”,”name”: “How Can I Maintain My Lathe Spindle Bearings To Extend Their Lifespan After Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe spindle bearings in good shape, you need to clean them regularly. Use a soft cloth to wipe off dust and dirt. Make sure to add the right amount of oil to keep them smooth. Check them often to see if they feel loose or make noise. If you notice any problems, fix them quickly to help them last longer.”}}]}