Have you ever wondered how a lathe works? It spins, shapes, and cuts materials to create amazing things. But what keeps that spinning part safe and steady? That’s where the lathe spindle lock mechanism comes into play. This clever little device makes sure the spindle stays still when you need it to.

Imagine trying to tighten a screw while it’s spinning. It would be just about impossible! The lathe spindle lock solves that problem. It allows you to work on your projects confidently. You can change tools or adjust pieces without worrying about the spindle moving.

Here’s a fun fact: the spindle lock has been used in various machines for years. It helps artisans and hobbyists alike. So next time you hear about a lathe, remember the important role of that lock. Understanding how it works can improve your skills too! Ready to dive deeper into the world of lathe spindle locks? Let’s explore this fascinating topic together!

Comprehensive Guide To Lathe Spindle Lock Mechanism

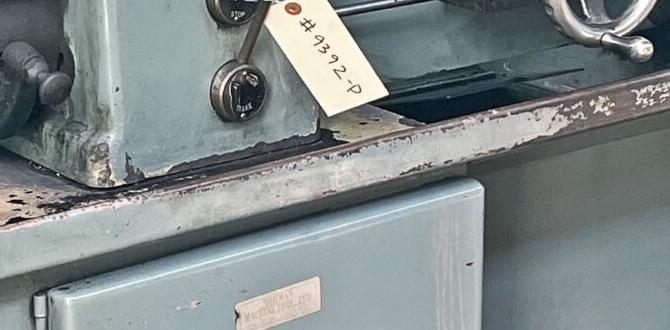

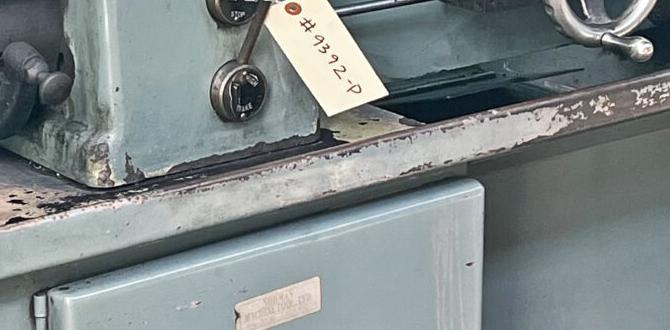

Lathe Spindle Lock Mechanism

The lathe spindle lock mechanism plays a vital role in ensuring safety while working with lathes. This feature allows the spindle to stay still during tool changes or maintenance, preventing accidents. Imagine trying to swap tools while the spindle is spinning—it could be dangerous! Knowing how to use this mechanism can save you time and help keep your workspace secure. Plus, it enhances the precision of your work, making every cut more accurate.What is a Lathe Spindle Lock Mechanism?

Definition and purpose of lathe spindle lock mechanism. Importance in machining and safety.A lathe spindle lock mechanism is a handy device used to secure the spindle in place. Think of it as a superhero cape that keeps everything safe while you work. This mechanism is crucial in machining because it prevents unwanted movement. It ensures precise and smooth operations, which makes a big difference in the quality of your work. Plus, it keeps your fingers safe from unexpected whirring! Safety first, right?

| Purpose | Importance |

|---|---|

| Secures spindle during operations | Enhances machining accuracy |

| Prevents accidental movement | Improves safety for the user |

Components of a Lathe Spindle Lock Mechanism

Key components involved in the mechanism. Materials used in construction.The lathe spindle lock mechanism has key parts that work together smoothly. First, there’s the lock lever. It helps hold the spindle tight, so it won’t move unexpectedly. Next, we have the spindle lock pin. This little guy pops in to secure things in place. The spring mechanism ensures everything springs back when you’re done locking. Most of these parts are made of strong metals like steel to resist wear. Here’s a quick look:

| Component | Material |

|---|---|

| Lock Lever | Steel |

| Spindle Lock Pin | Steel |

| Spring Mechanism | High-Carbon Steel |

These parts work together like a pizza team, keeping everything safe and sound while you work. Remember, with a good mechanism, you’ll avoid those “uh-oh” moments!”

How to Operate a Lathe Spindle Lock Mechanism

Stepbystep instructions on operation. Common mistakes to avoid during operation.The lathe spindle lock mechanism helps keep your workpiece steady. First, ensure the lathe is turned off. Then, locate the spindle lock lever. Pull or twist it to engage the lock. This locks the spindle in place.

To avoid common mistakes, remember these tips:

- Never lock the spindle while it’s spinning.

- Always check the lock is secure before starting work.

- Avoid using excessive force on the lock mechanism.

Following these steps ensures safety and accuracy during your lathe projects!

What should I do before using the lathe spindle lock mechanism?

Always turn off the machine and make sure the spindle is not in motion before locking it.

Benefits of Using a Lathe Spindle Lock Mechanism

Enhanced safety features. Improving machining precision.A lathe spindle lock mechanism offers many benefits. First, it greatly enhances safety. This feature helps prevent accidents by keeping the spindle in place. Operators can work with peace of mind, knowing their tools are secure.

Second, it improves machining precision. The lock ensures that the spindle doesn’t move unexpectedly. As a result, you get better cuts and clearer shapes.

- Enhanced safety features: Reduces risk of injury.

- Improving machining precision: Leads to accurate results.

Why is safety important in machining?

Safety is vital in machining to prevent injuries and protect workers. A secure machine helps keep everyone safe.

Common Issues and Troubleshooting

Typical problems encountered with spindle locks. Troubleshooting tips and solutions.Spindle locks can be a bit tricky. Sometimes, they refuse to engage or disengage. This can lead to frustration and a few choice words! Typical problems include misalignment and wear. Here’s a quick troubleshooting guide:

| Problem | Possible Cause | Solution |

|---|---|---|

| Spindle won’t lock | Misaligned parts | Check and adjust alignment |

| Lock engages slowly | Worn out components | Replace worn parts |

| Unexpected unlock | Faulty mechanism | Inspect and lubricate |

If you run into issues, don’t be shy! Grab a wrench and show that spindle lock who’s boss. After all, even machines need a little TLC sometimes!

Maintenance Tips for Lathe Spindle Lock Mechanisms

Regular maintenance routines. Signs of wear and when to replace components.To keep your lathe spindle lock mechanism happy, regular maintenance is key. Check it often for wear and tear, so you don’t end up with a stubborn spindle. If you hear strange noises or feel a wobble, it’s time to act! Replace worn parts before they cause a real mess. Here’s a quick table to help you keep track of the maintenance:

| Routine | Signs of Wear | Replacement Needed? |

|---|---|---|

| Check for Lubrication | Creaking Noises | Yes! |

| Inspect for Tightness | Wobbling | Yes! |

| Clean Regularly | Rust Formation | Definitely! |

By following these tips, you can keep your lathe spindle lock in tip-top shape. Remember, happy machinery makes happy operators!

Future Innovations in Lathe Spindle Lock Mechanisms

Emerging technologies and trends. How advancements may improve usability and safety.New ideas are changing lathe spindle lock mechanisms. These innovations focus on making tools safer and easier to use. One big trend is smart technology. Machines can now alert users when something is wrong. Other advancements include improved materials. Stronger materials reduce accidents. Here are some important benefits:

- Increased safety: Smart locks can prevent misuse.

- Better usability: Easy-to-use designs help everyone.

- Real-time feedback: Immediate alerts keep workers informed.

Keeping up with these changes will be key for users and makers alike.

How can new technologies improve lathe spindle lock mechanisms?

New technologies can make lathe spindle locks safer and easier to use. They offer alerts and notifications. This makes sure users know when it is safe to operate the machine.

Conclusion

In summary, a lathe spindle lock mechanism keeps the spindle secure during use. It prevents movement and ensures your work is precise. Understanding how this mechanism works helps you operate lathes safely and efficiently. Next, practice using it on a lathe, or read more about different types online. Your skills will improve with hands-on experience!FAQs

What Are The Common Types Of Lathe Spindle Lock Mechanisms, And How Do They Differ In Operation And Application?There are a few common types of lathe spindle lock mechanisms. One type is a lever lock, where you pull or push a lever to lock the spindle. Another type is a pin lock, where you push a pin into place to hold the spindle still. A third type is a screw lock, where you twist a screw to secure the spindle. Each type is easy to use, but they differ in how you operate them. For example, a lever lock is quick to use, while a screw lock takes a bit longer.

How Does A Lathe Spindle Lock Enhance Safety During Machining Operations?A lathe spindle lock helps keep the spinning part of the machine still. This is important when you want to change tools or check your work. When the spindle is locked, you can work safely without worrying it will spin and hurt you. It makes sure everything stays in place, so you can focus on your task.

What Are The Steps To Properly Engage And Disengage A Lathe Spindle Lock To Prevent Damage To The Machine?To use the lathe spindle lock, first, make sure the machine is turned off. Then, carefully locate the spindle lock lever. Pull the lever to lock the spindle in place. When you finish using it, push the lever again to unlock the spindle. Always check that everything is secure before turning on the lathe again.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Reliability Of A Lathe Spindle Lock Mechanism?To keep your lathe spindle lock working well, you should clean it regularly. Check for dirt or rust and wipe it down. You should also oil the moving parts lightly so they move easily. Tighten any screws or bolts if they get loose. Finally, check it often to make sure it’s not broken.

How Can The Design Of A Lathe Spindle Lock Impact The Overall Precision And Accuracy Of A Lathe’S Machining Process?The lathe spindle lock helps hold the spindle in place. If it’s strong and well-designed, the spindle won’t move wrong when we cut. This means the cuts will be more accurate and fit better. A weak lock can make mistakes in the work. So, the better the lock, the nicer our finished pieces will be!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Types Of Lathe Spindle Lock Mechanisms, And How Do They Differ In Operation And Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few common types of lathe spindle lock mechanisms. One type is a lever lock, where you pull or push a lever to lock the spindle. Another type is a pin lock, where you push a pin into place to hold the spindle still. A third type is a screw lock, where you twist a screw to secure the spindle. Each type is easy to use, but they differ in how you operate them. For example, a lever lock is quick to use, while a screw lock takes a bit longer.”}},{“@type”: “Question”,”name”: “How Does A Lathe Spindle Lock Enhance Safety During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe spindle lock helps keep the spinning part of the machine still. This is important when you want to change tools or check your work. When the spindle is locked, you can work safely without worrying it will spin and hurt you. It makes sure everything stays in place, so you can focus on your task.”}},{“@type”: “Question”,”name”: “What Are The Steps To Properly Engage And Disengage A Lathe Spindle Lock To Prevent Damage To The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use the lathe spindle lock, first, make sure the machine is turned off. Then, carefully locate the spindle lock lever. Pull the lever to lock the spindle in place. When you finish using it, push the lever again to unlock the spindle. Always check that everything is secure before turning on the lathe again.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Reliability Of A Lathe Spindle Lock Mechanism?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe spindle lock working well, you should clean it regularly. Check for dirt or rust and wipe it down. You should also oil the moving parts lightly so they move easily. Tighten any screws or bolts if they get loose. Finally, check it often to make sure it’s not broken.”}},{“@type”: “Question”,”name”: “How Can The Design Of A Lathe Spindle Lock Impact The Overall Precision And Accuracy Of A Lathe’S Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe spindle lock helps hold the spindle in place. If it’s strong and well-designed, the spindle won’t move wrong when we cut. This means the cuts will be more accurate and fit better. A weak lock can make mistakes in the work. So, the better the lock, the nicer our finished pieces will be!”}}]}