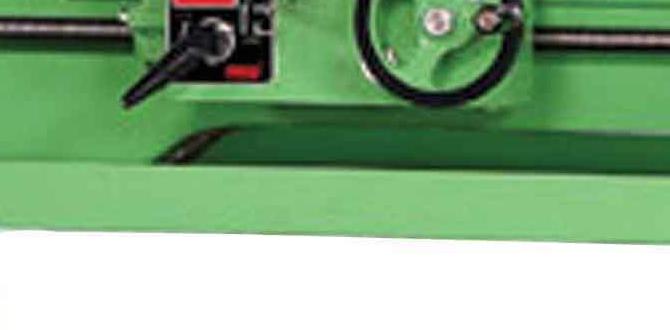

Have you ever wondered how to keep your lathe spindle in top shape? A clean spindle makes all the difference in how your machine works. It helps your tools perform better and last longer.

Imagine getting ready to start a project. You have your materials and tools ready. Suddenly, you notice dirt and grime on your lathe spindle. Yikes! This mess can cause serious problems.

A great cleaning method for the lathe spindle taper can save the day. But why does it matter so much? A clean taper ensures smooth operation and prevents wear and tear in your machine. That means fewer repairs and more projects!

In this article, we will explore effective lathe spindle taper cleaning methods. You’ll learn easy steps to keep your machine running smoothly. Let’s dive in and discover how simple cleaning can enhance your projects!

Effective Lathe Spindle Taper Cleaning Method Techniques

Lathe Spindle Taper Cleaning Method

Cleaning your lathe spindle taper is important for smooth operation. A clean taper ensures better grip and accuracy. Start by using a soft rag and a cleaning solution to wipe away grime. A brush can help reach tight spaces. Did you know that regular cleaning can extend your lathe’s life? Ignoring this task might lead to bigger issues down the road. Keep your equipment in top shape by following this simple cleaning method!Understanding Lathe Spindle Tapers

Definition and purpose of lathe spindle tapers. Types of spindle tapers commonly used in lathes.Lathe spindle tapers are special shapes used to hold tools on a lathe. They help the machine work better by keeping tools steady. Different tapers fit various machines and tasks. Here are some common types:

- MT (Morse Taper)

- CAT (Cat Taper)

- BT (Big Taper)

Each type has unique features that suit specific jobs. Understanding these tapers helps users pick the right tool and make their work easier.

What is a lathe spindle taper?

A lathe spindle taper is a conical shape at the end of the spindle that secures tools in place. It prevents slipping and ensures accurate cuts.

The Importance of Maintaining Clean Spindle Tapers

Effects of debris and contaminants on machining accuracy. Longterm benefits of regular cleaning.Keeping spindle tapers clean is crucial for smooth machining. Dust and dirt can sneak in and mess up accuracy. If your machine is dirty, it’s like trying to drive a car with a flat tire—awkward and slow! Regular cleaning helps avoid these issues. Plus, when you maintain them, you save money on repairs and parts. It’s like brushing your teeth; do it now and avoid a dentist visit later!

| Benefit | Description |

|---|---|

| Improved Accuracy | Clean tapers mean better fit and less wobble. |

| Longer Machine Life | Regular cleaning leads to fewer breakdowns. |

Tools and Materials Required for Cleaning

Common tools used for cleaning spindle tapers. Recommended cleaning solutions and materials.To keep your spindle tapers clean, you’ll need some trusty tools and materials. Think of them as your cleaning sidekicks! Essential items include soft brushes, lint-free cloths, and plastic scrapers. For cleaning solutions, mild degreasers or a vinegar and water mix can do wonders. Remember, you want to avoid anything too harsh – your lathe deserves gentle care!

| Tool/Material | Purpose |

|---|---|

| Soft Brush | Dust and debris removal |

| Lint-Free Cloth | Wipe down surfaces |

| Plastic Scraper | Remove stubborn grime |

| Mild Degreaser | Break down oils and dirt |

| Vinegar Solution | Natural cleaning agent |

Always remember, the right tools make cleaning feel like a breeze! Who knew cleaning could be so fun?

Step-by-Step Cleaning Process

Detailed instructions for manual cleaning. Procedures for using mechanical cleaning tools.Cleaning your lathe spindle taper doesn’t need to be a chore! Start with a soft cloth or brush to wipe off any dust. Use some grease cleaner for stubborn spots. Not too much elbow grease, though, we aren’t training for the Olympics! For those who love their gadgets, mechanical tools like a wire brush can save time. Just be gentle; we don’t want to scare away any delicate parts!

| Step | Manual Cleaning | Mechanical Cleaning |

|---|---|---|

| 1 | Wipe with soft cloth | Use wire brush |

| 2 | Apply grease cleaner | Check tool settings |

| 3 | Dry the area | Carefully clean |

Remember, a clean spindle helps your lathe run smoothly and keeps your projects on track! Plus, who doesn’t want the satisfaction of a job well done?

Preventive Maintenance Tips

Best practices to avoid taper contamination. Recommended cleaning frequency for optimal performance.Keeping your lathe spindle taper clean is like brushing your teeth. It helps avoid big problems later! To prevent contamination, always cover the taper when not in use. This keeps dust and grime away. It’s also smart to clean the taper every week if you’re using it often. Remember, what’s dirtier than a pig’s hoof? A dirty taper! So, stay clean to keep your machines happy!

| Best Practices | Cleaning Frequency |

|---|---|

| Cover the taper. | Weekly (for heavy use). |

| Wipe after each use. | Daily (if possible). |

Common Mistakes to Avoid

Frequent pitfalls in cleaning spindle tapers. Consequences of improper cleaning techniques.Cleaning spindle tapers can be tricky. Avoid common mistakes like using the wrong tools, which can scratch the surface. Scratches lead to poor fitting, making your job harder. Another pitfall is forgetting to check for debris. Even tiny bits can cause major issues. Neglecting proper cleaning can result in metal shavings ruining your work. So, keep it clean to keep everything running smooth—like a well-oiled machine! Remember, a clean spindle is a happy spindle!

| Common Mistakes | Consequences |

|---|---|

| Using abrasive tools | Scratches and poor fit |

| Ignoring debris | Major mechanical issues |

| Skipping cleaning steps | Ruins the entire job |

Conclusion

In conclusion, cleaning your lathe spindle taper is essential for smooth operation. You should regularly remove dirt and debris to prevent damage. Use simple tools like a brush or cloth for this task. Remember, a clean taper improves accuracy and extends your machine’s life. For more tips, check out guides on lathe maintenance. Happy lathing!FAQs

Sure! Here Are Five Questions Related To Lathe Spindle Taper Cleaning Methods:Sure! Here are five questions related to cleaning a lathe spindle taper: 1. Why do we need to clean the lathe spindle taper? We clean the taper so tools fit well and work safely. 2. What tools can we use for cleaning the taper? You can use a cloth, brush, or special cleaning solution. 3. How often should we clean the lathe spindle taper? We should clean it every time we change tools. 4. What happens if we don’t clean it? If we don’t clean it, tools can slip or break. 5. Can I use water to clean it? No, water can rust metal. Use a dry cloth instead.

Sure! Just let me know what question you would like me to answer, and I’ll do my best to help!

What Are The Best Tools And Materials To Use For Cleaning A Lathe Spindle Taper?To clean a lathe spindle taper, you can use a few simple tools. First, get a soft cloth or paper towel. This helps wipe away dirt and grease. You can also use a brush with soft bristles to reach tight spots. Finally, a cleaning solution like rubbing alcohol or mineral spirits works well to remove stubborn grime. Always remember to be gentle to keep the taper safe.

How Frequently Should Lathe Spindle Tapers Be Cleaned To Maintain Optimal Performance?You should clean lathe spindle tapers regularly to keep them working well. It’s a good idea to clean them after every use. If you use the lathe a lot, check them more often. Keeping them clean helps your lathe run smooth and last longer.

What Are The Common Contaminants Found On Lathe Spindle Tapers, And How Can They Affect Machining Accuracy?Common contaminants on lathe spindle tapers can include dirt, oil, dust, and metal shavings. These can make the taper uneven. When the taper isn’t smooth, your machine may cut inaccurately. This means the shapes you make might not be right or fit together well. Keeping the taper clean helps everything work better!

What Step-By-Step Process Should Be Followed For Effectively Cleaning A Lathe Spindle Taper?To clean a lathe spindle taper, you can follow these steps. First, turn off the machine and unplug it for safety. Next, gather some clean cloths and a brush. Then, gently wipe the taper with a cloth to remove dirt. If there’s tough grime, use the brush. Finally, check that it’s clean before plugging the machine back in.

Are There Any Specific Techniques To Prevent Damage To The Taper While Cleaning It?To clean a taper safely, you can use a soft cloth. Always wipe gently, avoiding scratches. Use a mild cleaner, not strong chemicals. Don’t use sharp tools or brushes, as they can cause harm. After cleaning, make sure it’s completely dry. This helps keep it safe and nice!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Spindle Taper Cleaning Methods:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions related to cleaning a lathe spindle taper: 1. Why do we need to clean the lathe spindle taper? We clean the taper so tools fit well and work safely. 2. What tools can we use for cleaning the taper? You can use a cloth, brush, or special cleaning solution. 3. How often should we clean the lathe spindle taper? We should clean it every time we change tools. 4. What happens if we don’t clean it? If we don’t clean it, tools can slip or break. 5. Can I use water to clean it? No, water can rust metal. Use a dry cloth instead.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you would like me to answer, and I’ll do my best to help!”}},{“@type”: “Question”,”name”: “What Are The Best Tools And Materials To Use For Cleaning A Lathe Spindle Taper?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean a lathe spindle taper, you can use a few simple tools. First, get a soft cloth or paper towel. This helps wipe away dirt and grease. You can also use a brush with soft bristles to reach tight spots. Finally, a cleaning solution like rubbing alcohol or mineral spirits works well to remove stubborn grime. Always remember to be gentle to keep the taper safe.”}},{“@type”: “Question”,”name”: “How Frequently Should Lathe Spindle Tapers Be Cleaned To Maintain Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should clean lathe spindle tapers regularly to keep them working well. It’s a good idea to clean them after every use. If you use the lathe a lot, check them more often. Keeping them clean helps your lathe run smooth and last longer.”}},{“@type”: “Question”,”name”: “What Are The Common Contaminants Found On Lathe Spindle Tapers, And How Can They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common contaminants on lathe spindle tapers can include dirt, oil, dust, and metal shavings. These can make the taper uneven. When the taper isn’t smooth, your machine may cut inaccurately. This means the shapes you make might not be right or fit together well. Keeping the taper clean helps everything work better!”}},{“@type”: “Question”,”name”: “What Step-By-Step Process Should Be Followed For Effectively Cleaning A Lathe Spindle Taper?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean a lathe spindle taper, you can follow these steps. First, turn off the machine and unplug it for safety. Next, gather some clean cloths and a brush. Then, gently wipe the taper with a cloth to remove dirt. If there’s tough grime, use the brush. Finally, check that it’s clean before plugging the machine back in.”}},{“@type”: “Question”,”name”: “Are There Any Specific Techniques To Prevent Damage To The Taper While Cleaning It?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean a taper safely, you can use a soft cloth. Always wipe gently, avoiding scratches. Use a mild cleaner, not strong chemicals. Don’t use sharp tools or brushes, as they can cause harm. After cleaning, make sure it’s completely dry. This helps keep it safe and nice!”}}]}