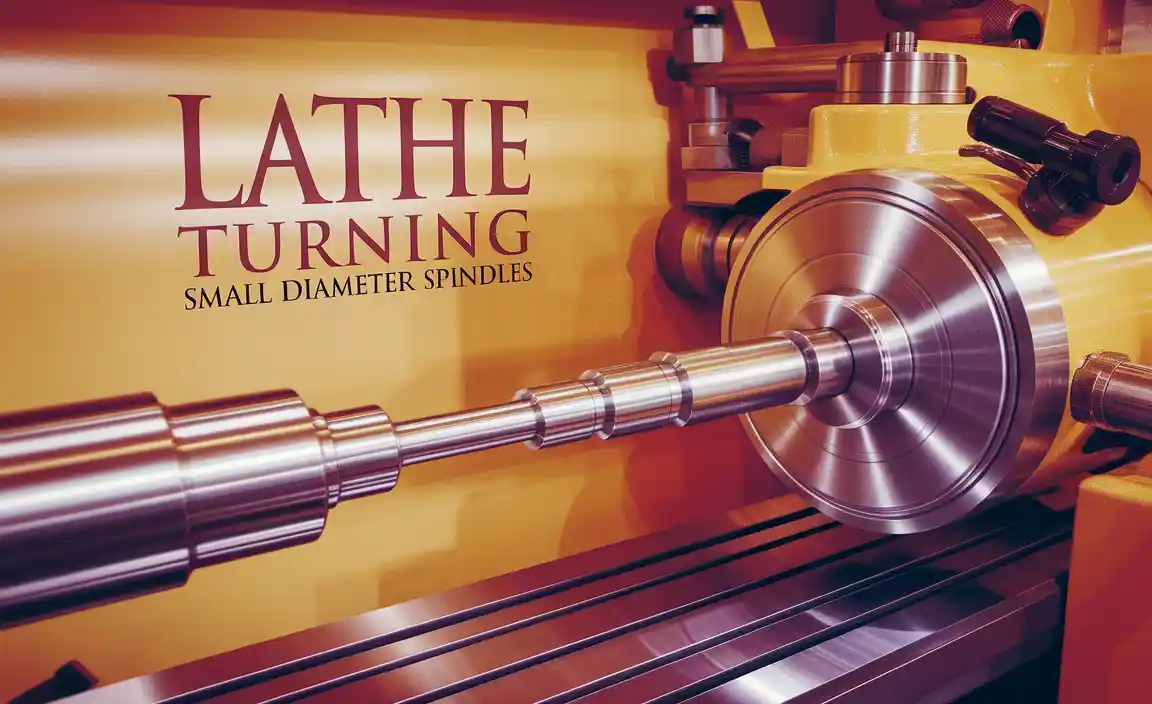

Have you ever tried to work with thin shafts on a lathe? It can be tricky, right? The smallest mistake can ruin everything. That’s where a lathe steady rest comes in. This neat tool helps support thin shafts while you shape or cut them.

Imagine you’re crafting a pencil or a small metal rod. If it wobbles, you’ll never get it just right. A lathe steady rest keeps those slender pieces steady and in place. It acts like a helping hand during your work.

Did you know that many woodworkers and metalworkers rely on a lathe steady rest to create precise items? It’s true! This tool seems simple, but it makes a big difference. Without it, many projects would end in frustration. So, let’s dive into how lathe steady rests work and why they are essential for thin shafts.

Lathe Steady Rest For Thin Shafts: Your Complete Guide

Lathe Steady Rest for Thin Shafts

A lathe steady rest is essential when working with thin shafts. It supports the workpiece, helping to prevent vibrations and bending. Imagine trying to balance a pencil with one hand while writing—it’s tricky! This tool makes sure your shafts stay straight during machining. Choosing the right steady rest boosts accuracy and quality. Plus, it ensures your project stays on track. A lathe steady rest could be the secret to your best work yet!Understanding Lathe Steady Rests

Definition and purpose of a steady rest. Importance in machining processes.A lathe steady rest is like a superhero for thin shafts. It holds and supports them while you shape or cut, preventing wobbles and keeping everything steady. Imagine trying to walk a tightrope without support; it’d be tricky! This tool is crucial in machining because it ensures precision and accuracy in your work. Without it, your project could turn into a game of “Guess Where the Shaft Went!” So, if you’re handling those delicate pieces, a steady rest is your best buddy!

| Purpose | Importance |

|---|---|

| Supports thin shafts | Increases accuracy |

| Prevents wobbling | Enhances quality |

| Improves safety | Reduces material waste |

Types of Lathe Steady Rests

Fixed vs. adjustable steady rests. Key features and benefits of each type.Lathe steady rests come in two main flavors: fixed and adjustable. Fixed steady rests are simple and easy to use. They provide stable support for thin shafts without much fuss. They don’t budge! Adjustable steady rests offer flexibility. You can change their size to fit different shaft widths. This means they can be used for a variety of projects. Do you need both? Well, if you have many shaft sizes, adjustable is your best buddy. If not, fixed might be just fine!

| Type | Key Features | Benefits |

|---|---|---|

| Fixed | Stable, no adjustments needed | Ideal for consistent jobs! |

| Adjustable | Customizable size | Great for various projects! |

Choosing the Right Steady Rest for Thin Shafts

Factors to consider: size, weight, and shaft diameter. Compatibility with various lathe models.Picking the right steady rest for your thin shafts can feel like finding a needle in a haystack. Size matters! You want one that fits snugly without weighing down your project. Don’t forget to check the shaft diameter too; it should match perfectly like puzzle pieces. Also, compatibility with your lathe is key. It’s like dating—if it’s not a match, it’ll just be a disaster! Choosing wisely will help you avoid any funny business.

| Factor | Description |

|---|---|

| Size | Should fit the shaft snugly. |

| Weight | Light enough for easy handling. |

| Shaft Diameter | Must match for stability. |

| Lathe Compatibility | Ensure it works with your specific model. |

Benefits of Using a Steady Rest for Thin Shafts

Improved accuracy and precision in machining. Reduction in vibration and deflection.Using a steady rest can turn your lathe work from wobbly to wonderful! First, it improves accuracy and precision, making sure those thin shafts are just right. Imagine crafting a pencil thin enough to steal from your little brother—perfectly crafted! Additionally, it cuts down on vibration and deflection. Less shaking means better results. Think of it as keeping your dance moves smooth and stylish instead of looking like a flopping fish!

| Benefit | Description |

|---|---|

| Improved Accuracy | Ensures thin shafts are machined precisely. |

| Reduced Vibration | Minimizes shaking and movement during machining. |

Installation and Setup of a Lathe Steady Rest

Stepbystep guide for proper installation. Tips for accurate positioning and adjustment.First, gather your tools and read the instruction manual like a cereal box—it’s full of good stuff! Place your steady rest on the lathe carefully. Tighten it down, but not too much, or it may cry for help. Next, adjust the arms to hug your thin shafts snugly. You want them comfy, not choked! To help you, here are some tips:

| Step | Tip |

|---|---|

| 1 | Check your lathe type. |

| 2 | Align the arms evenly. |

| 3 | Make small adjustments while it turns. |

With these simple steps, you’ll have your lathe steady rest set up like a pro. If you get lost, remember: it’s all about keeping those thin shafts steady. No one likes a wobbly ride!

Maintenance Tips for Longevity

Regular checks and cleaning practices. Signs of wear and when to replace components.Keeping your lathe steady rest in great shape is crucial. Regularly check for dirt or debris. Clean it often to avoid problems. Look out for signs of wear, like unusual noises or difficulty moving parts. If you notice any wear, it may be time to replace components. This helps keep everything running smoothly.

- Check for dirt daily.

- Listen for strange noises.

- Replace worn parts quickly.

How can I tell if my lathe steady rest needs repair?

Spotting signs of wear is easy. Look for rough movement or noise when working. If parts feel loose or loose, service may be due. Regular checks help you catch issues early.

Common Issues and Troubleshooting

Identifying problems related to steady rest use. Solutions for common machining challenges.Problems with a lathe steady rest can pop up like popcorn in a microwave! Common issues include wobbling or vibrations that happen when the steady rest isn’t set properly. To fix this, make sure your shaft is centered and securely held in place. Also, check for wear and tear on the steady rest pads. Regular maintenance is key to preventing headaches. If things still go awry, adjusting the arm might just do the trick! Troubleshooting these little downs can lead to smoother machining times.

| Issue | Solution |

|---|---|

| Wobbling | Center the shaft and tighten the hold. |

| Vibrations | Check stability and wear on pads. |

| Poor Finishing | Adjust the steady rest arm. |

Case Studies: Success Stories with Steady Rests

Examples of industries benefiting from steady rests. Impact on production efficiency and quality.Many industries find steady rests for thin shafts very helpful. Manufacturing, automotive, and aerospace sectors use them to boost quality. These tools keep materials steady. This helps machines work better. As a result, production becomes faster and smoother.

- Improved quality of parts

- Less waste of material

- Faster production times

- Greater machine life

One company reported a 30% increase in production speed after using a steady rest. This shows how important these tools can be for success in different fields.

What are the benefits of using a steady rest for thin shafts?

Using a steady rest can improve precision and reduce vibrations. This leads to better products and less waste.

Future Trends in Lathe Technology

Innovations in steady rest design and functionality. Implications for machining thin shafts in various industries.New designs for lathe steady rests are changing how we work with thin shafts. These innovations make steady rests lighter and stronger. They help hold small parts better during machining. Many industries, like automotive and aerospace, rely on these improvements. With better steady rests, manufacturers can create precise and durable parts. This leads to better products for everyone.

Why are steady rests important for machining?

Steady rests help keep thin shafts stable during machining. When they are secure, the machining goes smoothly, and the final product is of high quality.

Conclusion

In conclusion, using a lathe steady rest is crucial for working with thin shafts. It helps keep the shaft steady and prevents wobbling. By improving your setups, you’ll get better results in your projects. Remember, a steady rest can save you time and effort! For more tips, consider reading about different lathe tools and techniques.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Steady Rests For Thin Shafts:A lathe steady rest helps keep thin shafts steady while you work on them. It stops the shafts from wobbling. This makes it easier to cut or shape the material. You can adjust the steady rest to fit different sizes. Using it makes your work better and safer!

Sure! I’ll do my best to keep it simple and clear for you. Please ask your question!

What Is The Primary Function Of A Steady Rest When Working With Thin Shafts On A Lathe?A steady rest helps hold thin shafts while you work on them with a lathe. It keeps the shaft steady and prevents it from bending or wobbling. This way, you can make smooth cuts without making mistakes. Using a steady rest makes your work easier and safer.

How Do You Properly Set Up And Align A Steady Rest For Optimal Support Of A Thin Shaft?To set up a steady rest for a thin shaft, first, place the steady rest close to the shaft. Then, turn the knobs to adjust the support arms. Make sure the arms touch the shaft evenly on all sides. Next, check that the shaft can spin freely without bumping. Finally, double-check everything to ensure it’s tight and secure.

What Are The Key Differences Between Using A Steady Rest For Thin Shafts Compared To Thicker Workpieces?Using a steady rest for thin shafts helps keep them steady while working. Thin shafts are more wobbly, so we need extra support. For thicker workpieces, they are heavier and more stable on their own. So, we don’t always need a steady rest for them. It’s like how a thin pencil needs a grip, but a thick marker can stand alone.

What Materials Are Commonly Used For Constructing Steady Rests, And How Do They Impact The Performance When Machining Thin Shafts?We commonly use metal and plastic to make steady rests. Metal is strong and keeps everything in place. Plastic is lighter and can be softer, which helps protect thin shafts. If you use the right material, it helps the machine work better by preventing bending or vibrations. This makes sure the thin shafts stay steady while we work on them.

What Common Challenges Might Arise When Using A Steady Rest With Thin Shafts, And How Can They Be Mitigated?When using a steady rest with thin shafts, you might face a few problems. The shafts can wobble or bend if the rest is too tight. This can make it hard to work carefully. To fix this, you should adjust the steady rest gently and use soft padding. This helps hold the shaft without squeezing it too hard.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Steady Rests For Thin Shafts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe steady rest helps keep thin shafts steady while you work on them. It stops the shafts from wobbling. This makes it easier to cut or shape the material. You can adjust the steady rest to fit different sizes. Using it makes your work better and safer!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I’ll do my best to keep it simple and clear for you. Please ask your question!”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Steady Rest When Working With Thin Shafts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A steady rest helps hold thin shafts while you work on them with a lathe. It keeps the shaft steady and prevents it from bending or wobbling. This way, you can make smooth cuts without making mistakes. Using a steady rest makes your work easier and safer.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Steady Rest For Optimal Support Of A Thin Shaft?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a steady rest for a thin shaft, first, place the steady rest close to the shaft. Then, turn the knobs to adjust the support arms. Make sure the arms touch the shaft evenly on all sides. Next, check that the shaft can spin freely without bumping. Finally, double-check everything to ensure it’s tight and secure.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Using A Steady Rest For Thin Shafts Compared To Thicker Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a steady rest for thin shafts helps keep them steady while working. Thin shafts are more wobbly, so we need extra support. For thicker workpieces, they are heavier and more stable on their own. So, we don’t always need a steady rest for them. It’s like how a thin pencil needs a grip, but a thick marker can stand alone.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Constructing Steady Rests, And How Do They Impact The Performance When Machining Thin Shafts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We commonly use metal and plastic to make steady rests. Metal is strong and keeps everything in place. Plastic is lighter and can be softer, which helps protect thin shafts. If you use the right material, it helps the machine work better by preventing bending or vibrations. This makes sure the thin shafts stay steady while we work on them.”}},{“@type”: “Question”,”name”: “What Common Challenges Might Arise When Using A Steady Rest With Thin Shafts, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a steady rest with thin shafts, you might face a few problems. The shafts can wobble or bend if the rest is too tight. This can make it hard to work carefully. To fix this, you should adjust the steady rest gently and use soft padding. This helps hold the shaft without squeezing it too hard.”}}]}