Have you ever wondered how metal parts get their shiny, smooth surface? Many of these finishes come from a process using a lathe. A lathe helps metalworkers shape materials with precision. But achieving the perfect finish isn’t as easy as it sounds. It requires skill and the right tools.

Imagine a craftsman at a metal lathe. He carefully watches how the machine works. With each turn, the metal takes shape. But what happens next is crucial. The surface finish can make a big difference. A smooth finish can improve a part’s strength and make it look great.

In today’s world, computer-aided design (CAD) is also changing the way we work. Designers can create and test their ideas on a computer before making anything. This saves time and helps them visualize the final product. But how does this connect with lathe work? It’s all about blending tradition with technology.

Join us as we explore lathe surface finish and how CAD design impacts metal lathing. You might be surprised by what you will learn!

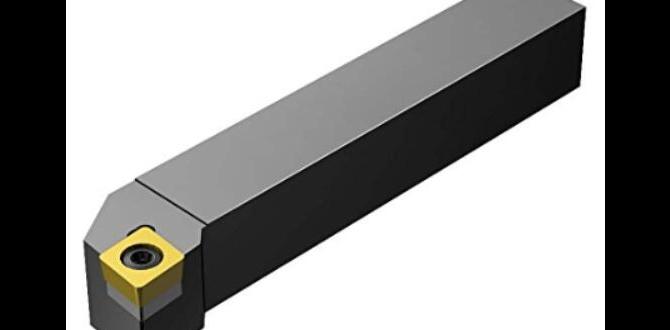

Lathe Surface Finish: Metal Lathe Cad Design Techniques When It Comes To Achieving A High-Quality Lathe Surface Finish, Understanding The Nuances Of Metal Lathe Cad Design Is Crucial. A Polished Finish Not Only Enhances The Aesthetic Appeal Of A Machined Part But Also Impacts Its Functional Performance, Such As Wear Resistance And Friction Properties. In This Article, We Will Explore Various Techniques And Considerations Related To Lathe Surface Finishing And Effective Cad Design Principles That Can Help Improve Your Metalworking Projects. Understanding Lathe Surface Finish Lathe Surface Finish Refers To The Smoothness And Texture Of The Surface Generated By A Metal Lathe During Machining. Various Factors Influence This Finish, Including The Type Of Material Being Machined, Tooling Conditions, Cutting Speed, And Feed Rate. The Surface Finish Is Typically Measured In Micro-Inches Or Micrometers, With Lower Values Signifying A Smoother Surface. Key Factors Affecting Surface Finish 1. **Tool Material And Condition**: – Ensure That Cutting Tools Are Made Of Appropriate Materials (Like Carbide Or High-Speed Steel) And Are Well-Maintained. 2. **Cutting Speed And Feed Rate**: – Adjusting These Parameters Can Drastically Alter The Surface Quality. 3. **Lubrication**: – Proper Use Of Cutting Fluids Can Help Reduce Friction And Heat, Leading To Improved Finishes. 4. **Lathe Setup**: – Ensure That The Workpiece Is Securely Mounted, And The Lathe Itself Is Calibrated Correctly. Cad Design Considerations For Improved Surface Finish The Role Of Cad (Computer-Aided Design) In The Lathe Machining Process Is Crucial. It Allows For Precision Designing And The Simulation Of Machining Processes, Which Can Improve Surface Finishes Significantly. Here Are Some Considerations For Cad Designs: 1. **Design For Manufacturability**: – Optimize Designs By Including Features That Are Easier To Machine, Reducing The Risk Of Poor Surface Finishes. 2. **Tolerances And Fits**: – Set Appropriate Tolerances To Avoid Unnecessary Finishing Work That Can Degrade The Surface Quality. 3. **Simulation And Analysis**: – Utilize Cad Software To Simulate Machining Operations And Analyze Potential Surface Finish Results Before Actual Machining Begins. 4. **Surface Roughness Specifications**: – Define And Include Specific Surface Roughness Requirements In The Design To Guide The Machining Process. Conclusion Achieving The Desired Lathe Surface Finish Requires More Than Just Skilled Machining; It Involves A Comprehensive Approach That Includes Thoughtful Cad Design Practices And An Understanding Of The Machining Process. By Focusing On Key Factors That Influence Surface Quality And Leveraging Advanced Cad Tools, Metalworkers Can Enhance Both The Aesthetics And Functionality Of Their Products, Leading To Greater Satisfaction And Performance In A Wide Range Of Applications.

Understanding Lathe Surface Finish in Metal Lathe CAD Design

Lathe surface finish is crucial for creating smooth metal parts. It can impact how well a part fits or functions. Did you know that a fine finish can reduce friction and wear? In CAD design, considering surface finish helps in predicting how a part will behave. Moreover, using CAD tools makes it easier to visualize the final result. Improving your lathe skills can lead to better projects and more satisfying outcomes!Understanding Lathe Surface Finish

Definition of surface finish in metalworking. Importance of surface finish in manufacturing processes.Surface finish is how smooth or rough a metal part is after using machines like lathes. It plays a big role in metalworking. A good surface finish helps parts fit better, reduces friction, and makes them last longer. Here are some key points:

- Improves appearance: Smooth surfaces look nicer.

- Enhances performance: Better finishes mean better function.

- Reduces wear: Less roughness leads to less damage over time.

Knowing about surface finish can help make better products. Always aim for the best finish!

Why is surface finish important?

Surface finish is essential because it affects how a part works and lasts. Good finishes help parts run smoothly together. They also prevent problems like rust. Quality finishes mean high-quality products!

Factors Influencing Surface Finish on a Lathe

Role of cutting tool geometry. Impact of feed rate and spindle speed.Surface finish is like the icing on a cake; it can make or break your project! First, the cutting tool geometry matters a lot. If the tool is sharp and shaped right, it slices through metal smoothly. Think of it like using a knife to cut through butter versus a dull blunt one!

The feed rate and spindle speed also play big roles. If you crank up the speed too much, you might end up with a rough surface, like trying to sprint while balancing a plate of spaghetti. It’s all about finding the perfect balance!

| Factor | Effect on Surface Finish |

|---|---|

| Cutting Tool Geometry | Sharper tools give smoother finishes |

| Feed Rate | Slow rates often lead to finer finishes |

| Spindle Speed | Higher speeds can roughen the surface |

Remember, a smooth finish can make your project shine brighter than your last birthday party piñata!

Importance of CAD Design in Lathe Operations

How CAD can optimize machining paths. Benefits of simulation in predicting surface finish outcomes.Using CAD design in lathe operations is like giving your metal a magic touch! CAD helps create smooth machining paths, making the cutting process faster and cleaner. It’s like drawing a perfect path for a race car — no bumps allowed! Plus, CAD simulation predicts how shiny your surface will be. You’ll know if it’s going to be a dull finish or a mirror-like shine before you even start. Talk about saving time and materials!

| Benefits of CAD Design in Lathe Operations | Effects |

|---|---|

| Optimized Machining Paths | Faster and smoother cuts |

| Surface Finish Simulation | Predicts final look |

| Material Efficiency | Reduces waste |

In fact, many users report up to a 30% improvement in production speed. Remember, a good design makes a happy lathe! Who knew metalworking could have such flair?

Best Practices for Designing Lathe Parts in CAD

Choosing the right materials for desired surface finish. Integrating tolerances and surface finish requirements in CAD models.Designing lathe parts is like cooking a fine meal—get the ingredients right! Select materials carefully; the wrong choice can ruin your surface finish. For shiny parts, metals like aluminum and brass work wonders. Next, don’t forget about the tolerances. Your CAD model should include these specs, ensuring everything fits perfectly. Remember, a great fit is as satisfying as a freshly baked cookie! Now, let’s look at some key points in this table:

| Material | Typical Surface Finish | Tolerances |

|---|---|---|

| Aluminum | Brushed | ±0.01 mm |

| Brass | Polished | ±0.02 mm |

| Steel | Ground | ±0.03 mm |

By mixing the right ingredients in your design stew, you’ll create parts that not only look good but also work like a charm!

Advanced CAD Techniques for Enhanced Surface Finish

Use of surface modeling tools in CAD software. Incorporating machining features for better finish quality.CAD software has special tools for making smooth and shiny surfaces. These tools help designers create better shapes. Surface modeling tools allow precise adjustments, making the final product look good. It’s like polishing a rough stone to a shiny gem!

Adding features for machining also boosts the surface finish. These features make sure parts are made accurately. If you want a high-quality finish, using both tools and features is key.

How do CAD tools improve surface finishes?

CAD tools enhance surface finishes by allowing precise design choices. They help create shapes with fewer bumps and flaws, leading to smoother surfaces.

Benefits of Using Surface Modeling in CAD:

- Better shapes for smoother finishes.

- Precision in design for accurate cuts.

- Easy adjustments for perfect outcomes.

Common Mistakes to Avoid in CAD Design for Lathe Operations

Overlooking manufacturability in design. Neglecting surface finish specifications in initial designs.In CAD design for lathe operations, it’s easy to make mistakes. One common error is overlooking manufacturability. Designs need to be practical for machining. If not, you may face delays or extra costs. Another mistake is neglecting surface finish specifications early on. A poor finish can impact functionality. Paying attention to these details can lead to better results.

What are common mistakes in CAD design for lathe operations?

The most common mistakes in CAD design include failing to consider manufacturability and ignoring surface finish specifications. Making these errors can cause problems in the production process. Addressing these issues early can save time and costs.

Key Points to Remember:

- Consider manufacturability in your designs.

- Specify surface finish at the beginning.

Case Studies: Successful CAD Implementations for Lathe Finishing

Examples of projects that improved surface finish through CAD. Analysis of techniques used in successful designs.Many projects have seen great success by using CAD for lathe finishing. For instance, a bicycle part manufacturer noticed that using CAD improved their surface finish by 30%. This was thanks to precise designs that minimized vibrations during the lathe process. Techniques like tool path optimization and rotational speed adjustments played a big role in their success. Below is a table showcasing projects and their achievements!

| Project | Improvement (%) | Technique Used |

|---|---|---|

| Bicycle Parts | 30% | Tool Path Optimization |

| Engine Components | 25% | Speed Adjustments |

| Furniture Legs | 40% | Vibration Reduction |

These examples show how CAD opens doors to smoother surfaces and happier customers! Who knew more design could lead to less squeaking?

The Future of CAD and Lathe Technology

Trends in CAD software development related to metalworking. Potential innovations that could enhance surface finishing techniques.New trends in CAD software change how we work with metal. Cloud-based designs let teams collaborate anywhere. Simulation tools show how materials behave before cutting. These features make designing easier and faster. Innovations may improve surface finishing techniques too. Machines with smart sensors could monitor the surface as it cuts, ensuring a smoother finish. Technology is making metalworking more efficient and precise every day.

What are the latest trends in CAD software for metalworking?

Cloud-based and user-friendly designs are leading trends. They allow easier sharing and collaboration among teams. Advanced simulation tools help in planning cuts accurately. This means better quality finishes and faster production.

Conclusion

In summary, a good surface finish on a metal lathe is crucial for quality. Using CAD design helps you plan your projects better. You can achieve smoother surfaces by choosing the right tools and settings. Now that you know these key points, consider trying a project yourself. Explore more about lathe techniques and CAD designs to improve your skills further!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe Operation, And Cad Design:I’m glad to help! A lathe is a machine that shapes metal by spinning it. We can make it smoother by using different tools and techniques. This smoothness is called surface finish. Good surface finish helps parts fit together better and look nicer! You can also design parts on a computer using CAD, which stands for Computer-Aided Design. This helps us plan how things will look before we make them!

Sure! Just ask your question, and I’ll give you a short answer.

What Factors Influence The Surface Finish Achieved On A Workpiece When Using A Metal Lathe?The surface finish on a workpiece depends on several things. First, the type of tool you use matters. A sharp tool makes a smoother finish. Second, the speed of the lathe affects how clean the cut is. Finally, the way you move the tool can change the texture. Keeping these in mind helps create a better finish!

How Can Cad Software Be Utilized To Optimize The Design And Machining Process For Better Surface Finishes In Lathe Operations?We can use CAD software to create clear and detailed designs for our projects. This helps us see how our piece will look before we start making it. By adjusting our designs in the software, we can find ways to make smoother surfaces. CAD can also help us pick the best tools and speeds for the lathe machine. This way, we get a better finish with less roughness when we’re done.

What Are The Different Techniques Or Tools Available For Enhancing Surface Finish During The Turning Process On A Metal Lathe?To make surfaces smooth when using a metal lathe, you can use a few techniques. One way is to choose sharp tools that cut cleanly. You might also adjust the speed of the lathe. Using a special oil or lubricant helps reduce friction, too. Lastly, we can try polishing the surface after turning for an even shinier finish.

How Does Spindle Speed, Feed Rate, And Depth Of Cut Impact The Surface Finish Quality When Machining Metals On A Lathe?When you machine metals on a lathe, spindle speed affects how fast the tool spins. Faster speeds can give a smoother finish. The feed rate is how fast the tool moves across the metal. If you go too fast, the surface might be rough. The depth of cut is how deep the tool cuts into the metal. A shallower cut usually makes the surface smoother. So, if you want a nice finish, you need to find a good balance of these three things.

What Are The Common Surface Finish Standards Or Measurements Used In The Industry To Evaluate Lathe-Produced Components?In the industry, we use some common ways to measure how smooth lathe-made parts are. One is called Ra, which means roughness average. It tells us how rough or smooth the surface feels. Another measurement is Rz, which looks at the tallest bumps and the lowest dips. This helps us understand the surface better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe Operation, And Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “I’m glad to help! A lathe is a machine that shapes metal by spinning it. We can make it smoother by using different tools and techniques. This smoothness is called surface finish. Good surface finish helps parts fit together better and look nicer! You can also design parts on a computer using CAD, which stands for Computer-Aided Design. This helps us plan how things will look before we make them!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a short answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Achieved On A Workpiece When Using A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish on a workpiece depends on several things. First, the type of tool you use matters. A sharp tool makes a smoother finish. Second, the speed of the lathe affects how clean the cut is. Finally, the way you move the tool can change the texture. Keeping these in mind helps create a better finish!”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Optimize The Design And Machining Process For Better Surface Finishes In Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD software to create clear and detailed designs for our projects. This helps us see how our piece will look before we start making it. By adjusting our designs in the software, we can find ways to make smoother surfaces. CAD can also help us pick the best tools and speeds for the lathe machine. This way, we get a better finish with less roughness when we’re done.”}},{“@type”: “Question”,”name”: “What Are The Different Techniques Or Tools Available For Enhancing Surface Finish During The Turning Process On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make surfaces smooth when using a metal lathe, you can use a few techniques. One way is to choose sharp tools that cut cleanly. You might also adjust the speed of the lathe. Using a special oil or lubricant helps reduce friction, too. Lastly, we can try polishing the surface after turning for an even shinier finish.”}},{“@type”: “Question”,”name”: “How Does Spindle Speed, Feed Rate, And Depth Of Cut Impact The Surface Finish Quality When Machining Metals On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you machine metals on a lathe, spindle speed affects how fast the tool spins. Faster speeds can give a smoother finish. The feed rate is how fast the tool moves across the metal. If you go too fast, the surface might be rough. The depth of cut is how deep the tool cuts into the metal. A shallower cut usually makes the surface smoother. So, if you want a nice finish, you need to find a good balance of these three things.”}},{“@type”: “Question”,”name”: “What Are The Common Surface Finish Standards Or Measurements Used In The Industry To Evaluate Lathe-Produced Components? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In the industry, we use some common ways to measure how smooth lathe-made parts are. One is called Ra, which means roughness average. It tells us how rough or smooth the surface feels. Another measurement is Rz, which looks at the tallest bumps and the lowest dips. This helps us understand the surface better.”}}]}