Have you ever wondered how metal parts get such smooth surfaces? It’s not magic; it’s science! The secret often lies in the lathe surface finish.

In a metal workshop, the lathe plays a crucial role. This machine spins metal pieces fast. As it turns, it removes rough spots. But the process doesn’t stop there. The right metal lathe chuck can make a huge difference, too. It holds the metal tightly, ensuring everything stays in place.

Imagine you have a rough block of metal. You want it to shine like a mirror. How do you do it? By using a lathe and a good chuck, you can create that perfect finish. Did you know that even a small change in technique can improve the final look? This can help your projects stand out.

Join us as we explore the fascinating world of lathe surface finish and discover tips for achieving the best results. You might find that perfect finish easier than you think!

Achieving Perfect Lathe Surface Finish With Metal Lathe Chuck

Lathe Surface Finish and Metal Lathe Chuck

Lathe surface finish plays a crucial role in shaping metal. A smooth finish helps parts fit together better. Did you know that the right chuck can improve surface texture? A metal lathe chuck holds the workpiece securely. When using it correctly, you’ll achieve an amazing, polished outcome. This strong grip ensures precision as you work. Remember, a great finish not only looks good but also enhances performance. Ready to create your perfect metal piece?Understanding Lathe Surface Finish

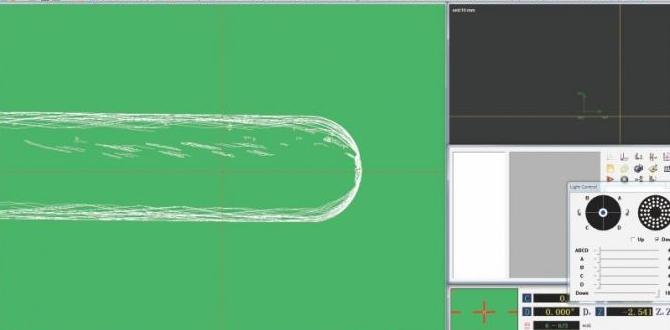

Definition and importance of surface finish in machining.. Common surface finish measurement methods..Lathe surface finish is how smooth or rough a metal piece is after machining. It is important because a good surface finish can improve how the part works and lasts. It also affects how it looks. Common ways to measure surface finish are:

- Roughness Average (Ra)

- Root Mean Square (RMS)

- Peak-to-Valley Height (PV)

These measurements help ensure parts fit and work well in machines.

Why is surface finish important?

Surface finish affects part performance and durability. Instead of rusting easily, smooth parts last longer and work better. Did you know that a well-finished part can improve energy efficiency? It’s true!

Factors Affecting Surface Finish on a Metal Lathe

The role of cutting speed and feed rate.. Impact of tool material and geometry on surface quality..Several factors impact the surface finish when using a metal lathe. First, cutting speed and feed rate are crucial. Higher speeds can create smoother surfaces, while a slower feed rate allows for finer details. Next, the tool material matters. Harder tools, like carbide, produce better finishes. The geometry of the tool also plays a role. Sharp tools cut cleaner, leading to a nice finish. Adjusting these elements can greatly improve your results.

How does cutting speed affect surface finish?

Higher cutting speeds create smoother finishes. Faster speeds reduce friction and heat, helping the tool make cleaner cuts.

What role does tool material play in surface quality?

- Carbide tools last longer and give better finishes.

- High-speed steel tools are common but may wear faster.

How does tool geometry impact results?

- Sharp cutting edges improve surface quality.

- Pointed shapes can reach tight spaces better, enhancing detail.

Choosing the Right Metal Lathe Chuck

Types of chucks: threejaw, fourjaw, and collet chucks.. Characteristics of chucks that influence surface finish..Picking the perfect metal lathe chuck can change your machining game. There are three main types: three-jaw, four-jaw, and collet chucks. Each has its quirks. Three-jaw chucks are great for quick jobs. They hold round items well, which is handy! Four-jaw chucks allow more flexibility, holding odd shapes securely. Collet chucks offer precision, especially for small parts. The chuck’s design affects surface finish, so choose wisely!

| Chuck Type | Best For | Surface Finish Impact |

|---|---|---|

| Three-Jaw | Quick jobs | Good |

| Four-Jaw | Odd shapes | Better |

| Collet | High precision | Best |

Preparation and Setup for Optimal Surface Finish

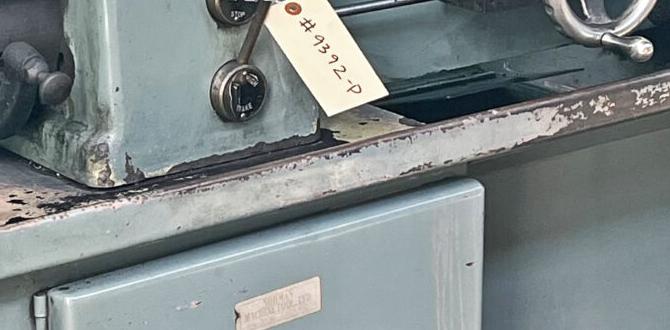

Importance of proper workpiece alignment and securing.. Premachining checks: tooling and lathe condition..Getting your workpiece lined up is key, like making sure your shoes match your outfit. If it’s off, things go sideways quickly! A secure gripping on the lathe is like giving your piece a warm hug, so it doesn’t bounce around. Next, check your tools and lathe condition like it’s your bike before a road trip. Everything needs to be sharp and ready. Remember, a smooth finish starts with a well-prepped setup!

| Preparation Step | Importance |

|---|---|

| Proper Workpiece Alignment | Prevents wobbling and uneven cuts |

| Securing the Workpiece | Avoids movements during cutting |

| Tool Inspection | Ensures sharpness for smooth finishes |

| Lathe Condition Check | Prevention of machine errors |

Advanced Techniques for Enhancing Surface Finish

Use of coolant and lubricants during machining.. Techniques such as fine boring and polishing operations..To make a metal surface smooth, using coolants and lubricants is important. They help cool the metal and reduce friction, leading to a better finish. Fine boring and polishing operations are also useful. These techniques improve precision and give a shiny look to the metal. Here are some ways to enhance surface finish:

- Coolants reduce heat during machining.

- Lubricants minimize wear on tools.

- Fine boring increases accuracy.

- Polishing creates a smooth surface.

Why are coolants and lubricants important?

Using coolants and lubricants during machining helps in achieving a cleaner and smoother surface finish. They keep the tools sharp and effective while working with metal. Applying these products results in better durability of equipment and higher quality outcomes.

Post-Processing for Improved Surface Finish

Appropriate methods for finishing after lathe work.. Equipment and tools for sanding, grinding, and polishing..After you’ve worked on your lathe, it’s time to make that surface shine! Finishing is the magic part where you turn rough metal into a smooth masterpiece. Techniques like sanding, grinding, and polishing are your best friends here. A trusty array of tools like sanders, rotating buffers, and polishing wheels can help. Remember, a good finish can make your project look as good as new, or at least less like it survived a wrestling match!

| Method | Tools | Description |

|---|---|---|

| Sanding | Sandpaper, Orbital Sander | Quickly removes rough spots and smooths surfaces. |

| Grinding | Grinder, Grinding Wheels | Perfect for removing excess material and shaping features. |

| Polishing | Polishing Wheel, Compound | Gives a mirror-like finish to your workpiece. |

Common Issues and Solutions in Achieving Desired Surface Finish

Identifying and correcting common surface finish problems.. Troubleshooting tips for different machining scenarios..Many problems can affect the surface finish of your metal work. It’s important to identify these issues to fix them quickly. Common problems include rough surfaces, chatter, and tool marks. Each problem may have different solutions.

- For rough surfaces, check your speed and feed rates.

- Chatter may be fixed by adjusting tool height.

- Tool marks can be reduced with proper tool sharpening.

Always observe your setup carefully to troubleshoot effectively. Sometimes, simple fixes can lead to a smoother finish.

Why is a good surface finish important?

A smooth finish is vital. It reduces friction and improves the part’s lifespan. Products that look neat also attract more buyers.

Real-World Applications of High-Quality Surface Finishing

Industries that benefit from precision surface finishes.. Case studies showcasing improved performance from enhanced finishing techniques..Many industries gain a lot from high-quality surface finishes. These finishes improve how well parts work and last longer. Here are a few fields that benefit:

- Aerospace: Smooth surfaces lead to better fuel efficiency.

- Automotive: Fine finishes increase engine performance and reduce noise.

- Medical: Precision surfaces ensure safety and effectiveness in tools.

One case study shows that an automotive company improved fuel economy by 10% after they enhanced their surface finishing techniques. This demonstrates how important surface finishing is for better performance!

Why are precision finishes important?

Precision finishes are crucial because they help parts work better and last longer. A smoother surface reduces friction and wear, which means machines can run more efficiently.

Conclusion

In summary, a lathe surface finish is crucial for quality metal work. A good metal lathe chuck holds materials securely for better results. To improve your skills, practice with different materials and settings. You can read more about lathe techniques online. Remember, hands-on experience will help you master these tools and techniques!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Metal Lathe Chucks:Sure! A lathe is a machine that shapes metal or wood. It spins the material while a tool cuts it. The surface finish is how smooth or rough the final piece feels. A good finish looks nice and works better. We use different chucks to hold the material in place while we work on it.

Sure! Please share the question you would like me to answer, and I’ll help you with it!

What Factors Influence The Surface Finish Of A Part Machined On A Metal Lathe?The surface finish of a part made on a metal lathe depends on a few things. First, the speed of the lathe matters. If you go too fast or slow, it can change the look. Second, the type of tool you use affects the smoothness. A sharp tool gives a better finish than a dull one. Finally, the material of the part also plays a role; some metals are easier to smooth than others.

How Do Different Types Of Lathe Chucks (E.G., Three-Jaw Vs. Four-Jaw) Affect The Accuracy And Surface Finish Of The Machined Workpiece?Different types of lathe chucks hold your workpiece in different ways. A three-jaw chuck holds round pieces well and is quick to use. A four-jaw chuck, however, is better for holding oddly shaped pieces tightly and accurately. This helps make the workpiece smoother. Better holding means better accuracy and a nicer finish!

What Techniques Can Be Employed To Improve The Surface Finish When Turning Metal On A Lathe?To improve the surface finish when turning metal on a lathe, you can try a few things. First, use a sharp cutting tool. A sharp tool makes clean cuts, which helps the surface look smooth. Second, you can slow down the lathe speed. A slower speed allows better control. Finally, use a good lubricant on the metal to reduce friction. This helps create a nicer finish, too!

How Does Tooling Selection, Including Cutting Tools And Inserts, Impact The Surface Finish Achieved On A Lathe?Choosing the right tools for a lathe really matters. If you pick good cutting tools and inserts, they help make the surface smooth. Tools that are sharp and strong cut better, leaving less roughness. If we use dull or weak tools, the surface may be bumpy. So, the right tools give us a nicer finish!

What Are The Recommended Speeds And Feeds For Optimizing Surface Finish On Various Metals Using A Lathe?To make a smooth surface on metal with a lathe, you need the right speeds and feeds. “Speed” means how fast the metal spins, and “feed” is how fast the tool moves across the metal. For soft metals like aluminum, use a higher speed and slower feed. For hard metals like steel, use a lower speed and a bit faster feed. Always remember to check the machine’s guide for exact numbers for each metal!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Metal Lathe Chucks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal or wood. It spins the material while a tool cuts it. The surface finish is how smooth or rough the final piece feels. A good finish looks nice and works better. We use different chucks to hold the material in place while we work on it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you would like me to answer, and I’ll help you with it!”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Of A Part Machined On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish of a part made on a metal lathe depends on a few things. First, the speed of the lathe matters. If you go too fast or slow, it can change the look. Second, the type of tool you use affects the smoothness. A sharp tool gives a better finish than a dull one. Finally, the material of the part also plays a role; some metals are easier to smooth than others.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Chucks (E.G., Three-Jaw Vs. Four-Jaw) Affect The Accuracy And Surface Finish Of The Machined Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of lathe chucks hold your workpiece in different ways. A three-jaw chuck holds round pieces well and is quick to use. A four-jaw chuck, however, is better for holding oddly shaped pieces tightly and accurately. This helps make the workpiece smoother. Better holding means better accuracy and a nicer finish!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Improve The Surface Finish When Turning Metal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To improve the surface finish when turning metal on a lathe, you can try a few things. First, use a sharp cutting tool. A sharp tool makes clean cuts, which helps the surface look smooth. Second, you can slow down the lathe speed. A slower speed allows better control. Finally, use a good lubricant on the metal to reduce friction. This helps create a nicer finish, too!”}},{“@type”: “Question”,”name”: “How Does Tooling Selection, Including Cutting Tools And Inserts, Impact The Surface Finish Achieved On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right tools for a lathe really matters. If you pick good cutting tools and inserts, they help make the surface smooth. Tools that are sharp and strong cut better, leaving less roughness. If we use dull or weak tools, the surface may be bumpy. So, the right tools give us a nicer finish!”}},{“@type”: “Question”,”name”: “What Are The Recommended Speeds And Feeds For Optimizing Surface Finish On Various Metals Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a smooth surface on metal with a lathe, you need the right speeds and feeds. Speed means how fast the metal spins, and feed is how fast the tool moves across the metal. For soft metals like aluminum, use a higher speed and slower feed. For hard metals like steel, use a lower speed and a bit faster feed. Always remember to check the machine’s guide for exact numbers for each metal!”}}]}