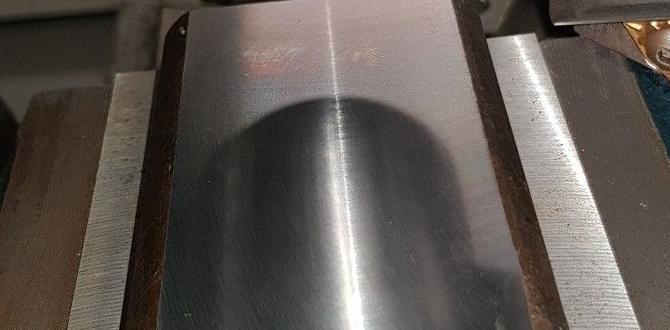

Have you ever wondered how metal workers achieve smooth and shiny surfaces on their projects? The secret often lies in an essential tool known as a lathe. But there’s more to it than just spinning metal. The right lathe surface finish is crucial for quality work.

Coolant plays a big role in this process. It helps keep everything cool and makes cutting easier. This is important because hot metal can warp or damage tools. Using the right coolant will help you get that perfect finish.

Let’s explore how lathe surface finish and coolant work together. Do you think the right coolant could be the key to a polished metal surface? It’s fascinating to see how these elements fit together to create amazing results in metalworking.

Achieving Optimal Lathe Surface Finish With Metal Lathe Coolant

Lathe Surface Finish and Coolant Choices

When using a metal lathe, achieving a smooth surface finish is essential. The right coolant can make all the difference. Coolants reduce heat, preventing damage to both the tool and the metal. They help improve the surface finish while increasing cutting speed. Did you know that a good coolant can even extend tool life? Choosing the right type can lead to better results and less wear on your machine. Quality matters!Understanding Surface Finish in Metalworking

Definition and importance of surface finish. Factors affecting surface finish quality.Surface finish is how smooth or rough a metal part feels. It matters because a good finish helps parts work better. A smoother finish means less friction, which can lead to longer-lasting tools and machines. Several factors influence surface finish quality:

- Tool sharpness: A sharp tool cuts better.

- Speed and feed rate: The right speed creates a smoother finish.

- Material type: Different materials behave differently when cut.

- Coolant use: Coolants, like metal lathe coolant, help keep the tool cool and reduce friction.

Understanding these factors ensures high-quality work in metalworking.

Why is surface finish important?

Surface finish impacts how well parts function. A smoother surface can lead to better performance.

The Role of Coolant in Metal Lathe Operations

Purpose of metal lathe coolant. Types of coolant and their properties.Coolant plays a key role in metal lathe operations. It helps cool down the tool and workpiece, preventing overheating. Overheating can cause material to warp or tools to wear out faster, which is not great for anyone’s wallet! Think of coolant as the spa day for metal; it keeps everything running smooth and prevents drama.

There are several types of coolant, each with special properties. Some coolants are water-based, providing excellent heat removal. Others are oil-based, offering better lubrication. While water-based coolants are like a refreshing splash in summer, oil-based ones are more like a cozy blanket. Let’s take a closer look:

| Type of Coolant | Properties |

|---|---|

| Water-Based | Good for cooling, easy to use |

| Oil-Based | Great lubrication, longer lasting |

Using the right type of coolant ensures a healthy machine life and helps achieve that shiny lathe surface finish! Remember, a happy machine makes happy metal!

Choosing the Right Coolant for Your Lathe

Watersoluble vs. oilbased coolants. Compatibility with materials and machining operations.Choosing the right coolant can feel like picking a favorite ice cream flavor—there are so many options! Two main types are water-soluble and oil-based coolants. Water-soluble coolants are great for cooling and are easy to clean up, like a superhero with a cape. On the other hand, oil-based coolants pack a punch for heavy-duty work but are messier, like a toddler with sticky candy.

It’s also important to consider the materials you’re working with. Some materials get cranky with certain coolants. Always check compatibility to avoid a meltdown in your workshop! Your machining operations will thank you later, and you might even save a bit on cleanup time.

| Coolant Type | Pros | Cons | Best For |

|---|---|---|---|

| Water-Soluble | Easy cleaning, good cooling | Can rust tools | Light machining |

| Oil-Based | Great for heavy work | Lurks like a sticky monster | Heavy-duty machining |

Remember, the right coolant can make all the difference. It’s like the perfect secret sauce for your machining success!

Application Techniques for Lathe Coolant

Best practices for coolant application. Common mistakes to avoid when applying coolant.Applying coolant properly is like giving your lathe a refreshing drink after a workout. First, remember to use just enough coolant to keep your workpiece cool but not so much that it creates a mini lake. Avoid common mistakes like spraying coolant on a dry surface or using the wrong type for your metal. This can lead to poor finishes or even damage! Check out these best practices:

| Best Practices | Common Mistakes |

|---|---|

| Use the right coolant type | Using too little or too much coolant |

| Apply at the correct pressure | Spraying on dry surfaces |

| Keep the nozzle clean | Ignoring coolant mix instructions |

Following these tips can lead to smoother surfaces and happier machines. Remember, a well-cared-for lathe is a happy lathe (and a smoother finish)! So, treat it nice!

Impact of Coolant on Surface Finish Quality

How coolant affects cutting temperature and tool wear. Case studies demonstrating improved surface finish with coolant.Coolant plays a crucial role in metal cutting. It keeps the cutting temperature down, which helps tools last longer and improves surface finish. A cool tool is a happy tool! With the right coolant, the cutting process becomes smoother, reducing wear and tear on equipment. In fact, studies show that using coolant can improve surface finish quality by over 40%. Here’s a little recap:

| Cutting Method | Surface Finish Without Coolant | Surface Finish With Coolant |

|---|---|---|

| Turning | Rough | Smooth |

| Milling | Choppy | Shiny |

So, next time you see a metal lathe sweating buckets, remember: it’s just trying to cool off for a smoother finish!

Maintenance and Management of Coolant Systems

Regular maintenance practices for coolant systems. Tips for prolonging coolant life and effectiveness.Keeping your coolant system in tip-top shape is crucial. Regular checks help avoid big headaches later! Make sure to change the coolant regularly—it’s like giving your lathe a fresh drink! To keep it effective, clean filters often. Want some tips? Here’s a quick table to help:

| Tip | Purpose |

|---|---|

| Check coolant levels | Prevents overheating |

| Replace old coolant | Maintains effectiveness |

| Clean filters | Improves flow |

Remember, a happy coolant equals a happy lathe! If it starts smelling funky, it’s probably time for a change! Keeping things clean is like giving your lathe a spa day.

Innovations in Metal Lathe Coolants

Latest advancements in coolant technology. Ecofriendly coolant alternatives and their benefits.Recent advancements in coolant technology make metalworking smoother than ever. New coolants now cool better and last longer, like the secret sauce for your favorite pasta! Eco-friendly coolants are gaining popularity too, providing great benefits, such as less harm to the environment and workers. They ensure less waste while keeping machines cool. Isn’t that a win-win?

| Type of Coolant | Benefits |

|---|---|

| Water-Soluble Coolants | Cooler operation, easy to clean |

| Bio-based Coolants | Less harmful, biodegradable |

| Synthetic Coolants | Durable, excellent lubricity |

With these innovations, metalworkers can enjoy improved surface finishes and boost productivity. Metal lathes, meet your cool new friends!

Conclusion

In conclusion, achieving a good surface finish on lathed metal parts is important. Use the right coolant to improve quality and extend tool life. Remember that the choice of coolant affects your results. You can experiment with different types to see what works best for you. For more tips, explore resources on machining and lathes!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe, And Coolant:Sure! A metal lathe is a machine that shapes metal. When we use it, we can make smooth surfaces. Coolant helps keep the metal cool and clean. A good surface finish makes our work look nice and work well. It’s important for making parts fit together properly!

Sure! Please ask your question, and I’ll be happy to answer it for you.

What Role Does Coolant Play In Achieving A Better Surface Finish When Machining Metal On A Lathe?Coolant helps keep the metal and the tools cool while we work on the lathe. When things get too hot, they can get messier and rougher. The coolant also washes away tiny bits of metal, making the surface smoother. So, using coolant helps us make the metal look nice and shiny.

How Does The Choice Of Coolant Affect Tool Life And Surface Quality During Lathe Operations?The coolant you choose can help your tools last longer. It makes them cooler and stops them from getting too hot. When your tools stay cool, they can cut better and make smoother surfaces on the metal. A good coolant also washes away tiny pieces of metal, keeping everything clean. This way, your finished pieces look nicer!

What Are The Best Practices For Applying Coolant To Enhance The Surface Finish While Turning Metal Parts On A Lathe?To make metal parts shine while using a lathe, we should use coolant properly. First, apply the coolant directly onto the metal. This helps keep it cool and reduces friction. Use enough to cover the cutting area, but not too much that it makes a mess. Lastly, clean the lathe and your work area after using the coolant. This keeps everything in good shape for next time!

Can Using The Wrong Type Of Coolant Negatively Impact The Surface Finish Of Machined Components? If So, How?Yes, using the wrong coolant can hurt the surface finish of machined parts. Coolant helps keep things cool and clean while we work. If it’s the wrong kind, it might not work well. This can leave rough spots or make the surface look bad. So, picking the right coolant is very important!

How Do Different Types Of Lathe Coolant (E.G., Water-Soluble, Oil-Based) Compare In Terms Of Performance And Impact On Surface Finish?Water-soluble coolants mix with water and are good for cooling. They can help keep the pieces shiny, but they might not lubricate as well. Oil-based coolants are thicker and help machines run smoothly. They usually give a better surface finish because they stick to the metal better. Each type has its own strengths, so we choose based on what we need!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe, And Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that shapes metal. When we use it, we can make smooth surfaces. Coolant helps keep the metal cool and clean. A good surface finish makes our work look nice and work well. It’s important for making parts fit together properly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to answer it for you.”}},{“@type”: “Question”,”name”: “What Role Does Coolant Play In Achieving A Better Surface Finish When Machining Metal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Coolant helps keep the metal and the tools cool while we work on the lathe. When things get too hot, they can get messier and rougher. The coolant also washes away tiny bits of metal, making the surface smoother. So, using coolant helps us make the metal look nice and shiny.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Coolant Affect Tool Life And Surface Quality During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The coolant you choose can help your tools last longer. It makes them cooler and stops them from getting too hot. When your tools stay cool, they can cut better and make smoother surfaces on the metal. A good coolant also washes away tiny pieces of metal, keeping everything clean. This way, your finished pieces look nicer!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Applying Coolant To Enhance The Surface Finish While Turning Metal Parts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make metal parts shine while using a lathe, we should use coolant properly. First, apply the coolant directly onto the metal. This helps keep it cool and reduces friction. Use enough to cover the cutting area, but not too much that it makes a mess. Lastly, clean the lathe and your work area after using the coolant. This keeps everything in good shape for next time!”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Coolant Negatively Impact The Surface Finish Of Machined Components? If So, How?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong coolant can hurt the surface finish of machined parts. Coolant helps keep things cool and clean while we work. If it’s the wrong kind, it might not work well. This can leave rough spots or make the surface look bad. So, picking the right coolant is very important!”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Coolant (E.G., Water-Soluble, Oil-Based) Compare In Terms Of Performance And Impact On Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Water-soluble coolants mix with water and are good for cooling. They can help keep the pieces shiny, but they might not lubricate as well. Oil-based coolants are thicker and help machines run smoothly. They usually give a better surface finish because they stick to the metal better. Each type has its own strengths, so we choose based on what we need!”}}]}