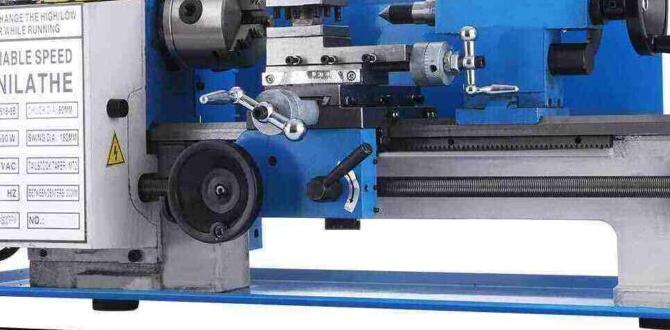

Have you ever wondered how metal parts get their shiny and smooth surfaces? It all comes down to the magic of lathe surface finish. Using a metal lathe, skilled workers shape and polish metals into precise forms. But there’s more to it than just spinning metal.

Now, picture this: You’re in a workshop, and the metal lathe whirs to life. You watch as the cutting tool pulls the metal closer, creating a cutting-edge finish. This process isn’t just art; it’s science, too! With the right settings, the lathe can achieve a surface finish that meets exacting standards.

Ever heard of a DRO? It stands for Digital Readout. This nifty tool helps operators track measurements in real-time. With a dro, you can be sure of getting the moves just right. The combination of lathe technology and the precision of a dro leads to stunning results.

Whether you’re a beginner or a pro, understanding lathe surface finish will take your skills to the next level. So, let’s dive deeper into what makes these tools so powerful and why they are essential for every metalworker.

Lathe Surface Finish: Enhancing Metal Lathe Dro Accuracy

Understanding Lathe Surface Finish and DRO

Lathe surface finish is crucial when working with metal lathes. It affects the final look and functionality of your project. A smoother surface often means better performance. Also, a Digital Readout (DRO) helps you measure dimensions accurately while you work. It eliminates guesswork, making your projects more precise. Did you know that a shiny finish can also reduce friction? This can lead to longer-lasting parts. Choosing the right techniques can make a big difference!Understanding Lathe Surface Finish

Definition of surface finish in machining. Importance of surface quality in metalworking applications.Surface finish in machining means how smooth or rough a metal’s surface is after it has been worked on. It’s like giving your metal a nice haircut—no one wants those pesky split ends! Good surface quality is super important in metalworking because it helps parts fit together better and work longer. A smooth finish reduces wear and tear, making your machine parts feel like they’re on a vacation instead of a bumpy road. Remember, no one likes a rusty nail!

| Surface Finish Quality | Impact on Performance |

|---|---|

| Rough Finish | Increased friction and wear |

| Smooth Finish | Better accuracy and longer lifespan |

Surface finish can even affect how easily a machine part can be cleaned. So, treat your metal like royalty! After all, a happy metal part is a productive metal part!

Factors Influencing Lathe Surface Finish

Impact of tool material and geometry. Role of cutting speed and feed rate. Influence of workpiece material and hardness.Several key factors affect how smooth a lathe surface finish can be. First, the tool material and its shape play a huge role. A sharper tool cuts better than a dull one, just like a superhero needs a good cape! Next, there’s cutting speed and feed rate. Cutting faster can lead to a smoother finish, but too fast could create a mess—like racing on a banana peel! Lastly, the workpiece material and how tough it is also make a difference. Softer metals often yield smoother finishes. Check out the table below for a quick guide:

| Factor | Effect on Surface Finish |

|---|---|

| Tool Material | Better tools = smoother finish! |

| Cutting Speed | Speed it up, but not too much! |

| Workpiece Material | Softer metals = smoother surfaces. |

Techniques for Improving Surface Finish

Different lathe operations that enhance surface quality. Use of finishing tools and abrasives. Implementing proper cutting fluid selection.To improve surface finish on a lathe, use several helpful techniques. Different lathe operations, like turning and facing, can boost quality. Finishing tools and abrasives smooth out rough surfaces. Choosing the right cutting fluid also plays a key role.

Here are some effective tips:

- Use fine-grit abrasives for a smooth touch.

- Adjust lathe speed for better results.

- Select cutting fluids that cool and lubricate well.

These techniques can lead to better finishes and help your projects stand out!

What lathe operations can enhance surface finish?

Turning and facing operations can enhance surface finish by removing material evenly, giving a better look to the final product.

Why are finishing tools important?

Finishing tools are important because they help remove small imperfections and make surfaces smoother, which improves the overall quality of work.

How does cutting fluid affect finish quality?

Cutting fluid affects finish quality by cooling the tool and workpiece, reducing friction and wear, leading to a cleaner cut.

Measuring Surface Finish Quality

Common metrics for assessing surface finish (Ra, Rz, etc.). Tools and methods for measurement (profilometers, etc.).Measuring how smooth the surface of a metal part is can feel like a treasure hunt. You have tools like profilometers that act like smart detective devices, checking every tiny bump and groove. Common metrics come into play here. Ra (Roughness Average) gives you a quick peek into the overall texture. Meanwhile, Rz (Average Maximum Height) dives a little deeper, examining the tallest peaks and lowest valleys. It’s like measuring the height of the tallest kid on the playground!

| Metric | Description |

|---|---|

| Ra | The average roughness over a surface area. |

| Rz | The average difference between the highest peak and lowest valley. |

Understanding these numbers not only helps you pick the right finish but makes your projects shine brighter than a freshly polished shoe!

Integrating DRO Systems for Enhanced Precision

Explanation of Digital Readout (DRO) systems and their benefits. How DRO systems improve surface finish consistency.Digital Readout (DRO) systems are tools that show precise measurements. They help users know exactly how much they are cutting or shaping. This accuracy is vital for achieving a great surface finish. With a DRO, you can avoid mistakes that might ruin your work. It keeps things consistent, making sure every piece is just right. This means less re-work and more finished products. You’ll save time and effort, boosting your overall results!

How do DRO systems help with surface finishing?

DRO systems improve surface finish consistency by providing real-time, precise measurements. This helps prevent errors and ensures that every cut is perfect.

Benefits of DRO Systems

- Increase accuracy of cuts

- Reduce chances of mistakes

- Save time on rework

Common Mistakes to Avoid

Errors in setup and alignment. Neglecting tool wear and its effects on finish. Misjudging cutting parameters.Setting up a metal lathe perfectly is key for good work. Here are some mistakes to watch out for:

- Errors in setup and alignment: Ensure your lathe is level. A tilted lathe can ruin your finish.

- Neglecting tool wear: Dull tools lead to poor surface quality. Check your tools often!

- Misjudging cutting parameters: Choose correct speeds and depths. This affects the final result.

Avoiding these mistakes will help you achieve a better surface finish every time you work on your metal lathe.

What are common mistakes when using a metal lathe?

Common mistakes include improper setup, not checking tool wear, and wrong cutting speeds. These errors can lead to a poor surface finish. Always pay attention to details!

Case Studies and Real-world Examples

Successful applications of optimum surface finish techniques. Comparative analysis of surface finishes achieved with vs. without DRO.Many businesses have found ways to use optimum surface finish techniques successfully. For example, machine shops using a digital readout (DRO) system achieved smoother metal surfaces. This leads to better performance and fewer errors.

In contrast, shops without DRO struggled to maintain quality. The differences are clear:

- Surface finish with DRO: High-quality, smooth

- Surface finish without DRO: Rough, inconsistent

These successful cases show how important using technology can be. With the right tools, businesses can improve their products and keep customers happy.

How does a DRO improve surface finishes?

A DRO removes guesswork and increases precision. It helps machinists measure and adjust cuts easily.

Key Benefits of Using DRO:

- Improves accuracy

- Reduces time

- Enhances product quality

Conclusion

In summary, a metal lathe with a digital readout (DRO) improves surface finish quality. It helps you make precise cuts, ensuring better results. Understanding how to use a DRO can boost your skills. If you’re interested, try practicing with different materials. Explore more resources on lathe techniques to enhance your projects and become a pro. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathes, And Digital Readouts (Dro):Sure! A lathe is a machine that spins metal to make it smooth. You can use it to create many shapes. The surface finish is how smooth or rough the metal looks after using the lathe. A Digital Readout (DRO) is a tool that shows you exact measurements when you cut metal. It helps you be very precise and makes your work easier.

Of course! Just ask your question, and I’ll give you a short and simple answer.

What Factors Influence The Surface Finish Quality When Machining Metal On A Lathe?When you machine metal on a lathe, several things affect the surface finish. First, the tools you use need to be sharp. A dull tool makes rougher surfaces. Second, the speed of the lathe matters; going too fast can cause bumps. Lastly, the type of metal also changes the finish; some metals are smoother than others.

How Can A Digital Readout (Dro) Improve Machining Accuracy And Surface Finish On A Lathe?A digital readout (DRO) shows you exactly where your tool is on the lathe. This helps you make precise cuts, so your pieces fit together better. With clear numbers, you can see how much metal to take off. This leads to smoother surfaces and nicer-looking parts. Using a DRO makes your work more accurate and easier!

What Are The Commonly Used Surface Finish Measurement Methods For Lathe-Turned Components?We can measure how smooth a lathe-turned piece is in different ways. One way is using a small tool called a profilometer. It moves across the surface and checks for bumps and dips. Another way is using a microscope to look closely at the surface. Lastly, we can also use a simple roughness gauge to get quick readings. These tools help us know if the surface is good enough for what we need!

How Does The Selection Of Cutting Tools And Speeds Affect The Final Surface Finish Of Machined Parts?Choosing the right cutting tools and speeds is really important for making smooth surfaces on parts we make. When you use sharp tools and the right speed, you get a nice finish. If the tools are dull or the speed is too fast, it can leave rough spots or bumps. So, picking the best tools and speeds helps us create better-looking parts. Always remember, sharp tools make smooth work!

What Maintenance Practices Can Ensure Optimal Performance Of A Metal Lathe To Achieve Better Surface Finishes?To keep your metal lathe working well, clean it regularly. Remove any metal shavings and dust after each use. Check the oil levels and add more if needed. Make sure all the parts are tight and not loose. Finally, sharpen the cutting tools to get smooth surfaces on your projects.