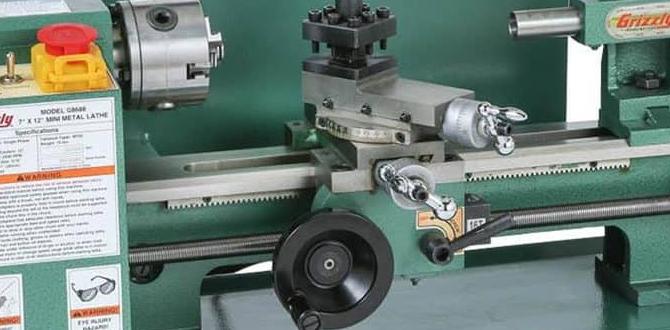

Have you ever wondered how metal parts get their smooth, shiny finish? One of the best tools for this job is a metal lathe. It creates precision parts that fit together perfectly. But there’s more to it than just turning metal. The secret lies in achieving the right lathe surface finish.

Imagine a gear that fits snugly into a machine. If its surface isn’t smooth enough, it can cause all sorts of problems. It might wear out quickly or even break. That’s why understanding lathe surface finish is so important.

Many people don’t realize that the quality of a metal lathe finish can affect how well a gear works. Did you know that small changes in the finishing process can lead to big differences in performance? Let’s explore how metal lathes create stunning finishes and why they matter in our daily lives.

Lathe Surface Finish: Achieving Perfection On Metal Lathe Gear

Lathe Surface Finish: Metal Lathe Gear

Lathe surface finish plays a crucial role in machining parts. A smooth finish improves a part’s performance and appearance. For metal lathe gear, a fine surface finish minimizes friction and wear. Did you know that the right tools and techniques can enhance the final output? Using proper feed rates and cutting speeds can change how well the gear performs. Understanding these factors makes a difference in any machining project. Don’t underestimate the power of a polished surface!Understanding Lathe Surface Finishes

Definition and importance of surface finish in machining. Different types of surface finishes and their characteristics.Surface finish is how smooth or rough a metal piece is after shaping. It affects how it looks and works. A good finish can reduce wear and increase strength. It is essential in machining for quality and safety. Different finishes have unique features:

- **Mirror Finish:** This is very shiny and smooth.

- **Rough Finish:** This is typically gritty and used for grip.

- **Matte Finish:** This has no shine and looks flat.

- **Textured Finish:** This adds patterns for decorative purposes.

Each type is important for different tasks. Choosing the right finish improves function and aesthetics.

What is the role of surface finish in machining?

Surface finish improves performance and durability. A smoother surface leads to better wear resistance and lower friction.

Factors Influencing Surface Finish in Metal Lathes

Material properties affecting surface quality. Tool types and their impact on finish quality.Different things can play a big role in how smooth metal surfaces turn out. The type of material is very important. Softer materials can leave a better finish than harder ones. This is because softer materials are easier to shape. Tool types also matter a lot. Sharp and clean tools will create a finer surface than dull ones. Using the right tool can make a huge difference in how something looks.

What material qualities affect surface finish?

Softer materials tend to result in a better finish. Harder materials can be tougher to work with, often leaving a rougher surface. Knowing your material can help you choose the right tools!

How do tools impact the finish quality?

- Sharp Tools: They cut better and leave smooth surfaces.

- Dull Tools: They can pull and tear the material, causing a rough finish.

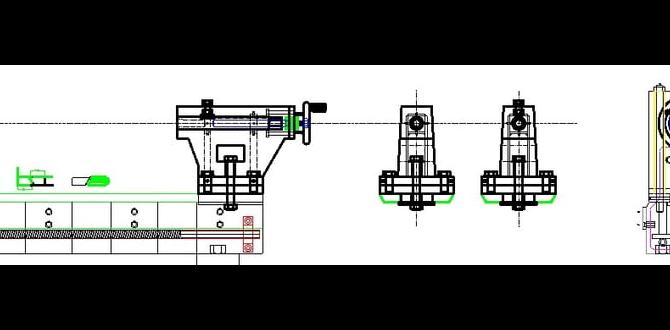

Surface Finish Measurement Techniques

Common methods for assessing surface finish. Tools and equipment used for accurate measurement.Measuring surface finish is like judging a cake’s frosting – it’s all in the details! Several common methods help us assess how smooth or rough a surface is. Optical methods use light to measure tiny bumps, while tactile methods, like using a stylus, physically feel the surface. There are tools like roughness testers and profilometers to ensure accuracy. Here’s a quick overview:

| Method | Description | Tool Example |

|---|---|---|

| Optical | Uses light to analyze surface texture | Interferometer |

| Tactile | Measures bumps by feeling them | Stylus roughness tester |

| Laser Scanning | Utilizes lasers for 3D surface mapping | Laser scanner |

Using the right equipment is key! It ensures our finished metal parts are smoother than a jazz musician’s solo.

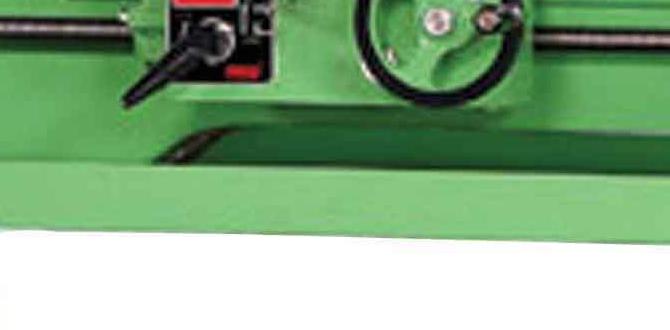

Techniques for Achieving Optimal Surface Finish

Best practices for cutting parameters (speed, feed, depth of cut). Influence of coolant and lubrication on surface quality.To achieve the best surface finish, proper cutting settings are important. Here are some best practices:

- Speed: Use moderate speeds. Higher speeds can enhance the finish but may cause heat, which is not good.

- Feed: Keep feed rates low for a smoother finish. This helps to reduce bumps and grooves.

- Depth of Cut: A shallow depth gives a finer finish. Deep cuts may lead to rough surfaces.

Coolant and lubrication also play a big role in surface quality. They help reduce heat and friction, leading to a better finish. Remember, a clean surface is a happy surface!

How does coolant affect lathe surface finish?

Coolant keeps the temperature lower and improves the lathe’s performance, resulting in a better surface finish.

Why is lubrication important?

Lubrication reduces friction, helping to prevent damage and ensuring a smoother output.

Common Issues Affecting Surface Finish

Identifying and troubleshooting common defects. Preventative measures for maintaining high quality.Surface finish problems can be quite the headache. From scratches to dull spots, identifying issues is key. Common defects include tool wear, wrong speeds, and feed rates. To keep your lathe on point, remember to check your tools often. Regular maintenance goes a long way! Always keep your workspace clean—it’s like giving your lathe a spa day! Here’s a quick table with some common issues:

| Issue | Solution |

|---|---|

| Tool Wear | Replace or sharpen the tool. |

| Incorrect Speed | Adjust RPM according to material. |

| Dirty Workspace | Keep it tidy; you’d want to work in a clean area too! |

By keeping an eye on these details, you can ensure a high-quality finish and less frustration!

Applications of High-Quality Surface Finishes in Gear Production

Benefits of improved surface finish in gear performance. Case studies showcasing advancements in gear manufacturing.High-quality surface finishes play a big role in how gears perform. A smooth surface makes gears work better together. It reduces friction, which means less wear and tear. When gears run smoothly, they last longer and are quieter. Some gear factories improved their designs. They found that better finishes led to less energy loss and higher efficiency. Here are some benefits:

- Improved durability

- Less noise

- Higher efficiency

- Lower production costs

What are some examples of gear production improvements?

Many companies have switched to advanced finishing techniques like honing and grinding. These methods create smoother surfaces that lead to better gear performance and reliability.

Future Trends in Lathe Finishing Technologies

Innovations in tooling and machining methods. The role of automation and AI in enhancing surface finish quality.New tools and techniques are changing how we make smooth surfaces on metal parts. Advances in tooling help us cut better and faster. With new machine designs, we get improved shapes and finishes. Automation and AI also help. They can check and adjust the process in real-time, ensuring a perfect finish every time.

- Smarter machines can adapt to different materials.

- Better tools reduce waste and save time.

- AI can predict and fix problems before they happen.

What role do automation and AI play in lathe finishing?

Automation and AI improve the quality of surface finishes by monitoring processes in real-time, making adjustments as needed, and reducing errors.

Conclusion

In conclusion, a lathe helps create smooth surfaces on metal parts. Understanding surface finish is crucial for making durable gears. You can improve your skills by practicing and experimenting with different techniques. So, why not try working on a small project? Explore more about lathe operations and gear making to deepen your knowledge. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish For Metal Lathe Gears:Sure! When we make gears on a lathe, the surface needs to be smooth. A smooth surface helps the gears work better and last longer. We can improve the finish by going slowly and using the right tools. It’s important to check the surface after we are done. This way, we can be sure it is just right!

Sure! Please provide the question you would like me to answer.

What Factors Influence The Surface Finish Quality Of A Gear Produced On A Metal Lathe?The surface finish quality of a gear made on a metal lathe can change because of different things. First, the type of metal we use matters. Softer metals can feel smoother. The speed of the lathe also affects how the gear turns out. If we go too fast, the finish might look rough. Lastly, sharp cutting tools help create a nicer, smoother surface on the gear.

How Does The Choice Of Cutting Tool Material Affect The Surface Finish Of Gear Teeth During Machining?The cutting tool material you choose can really change how smooth the gear teeth feel. Harder materials can cut better and leave a nicer finish. If you use a soft tool, it might scratch the teeth and make them rough. So, picking the right tool is important for a smooth surface. This helps the gears work better in machines.

What Are The Best Practices For Optimizing Cutting Speed And Feed Rate To Achieve A Superior Surface Finish On Lathe-Manufactured Gears?To get a smooth finish on gears made on a lathe, you should start with the right speed. Use a cutting speed that is not too fast or too slow. Then, set a feed rate that lets the tool cut evenly without pushing too hard. You can also check the tool regularly to make sure it stays sharp. Finally, always keep your work area clean to help with the finish.

How Can Post-Machining Processes, Such As Polishing Or Coating, Enhance The Surface Finish And Performance Of Lathe-Finished Gears?Polishing makes gears smooth and shiny. This helps them work better and last longer. Coating adds a thin layer that protects the gears. With these steps, gears can do their job without getting damaged easily. This means they are safer and can help machines run well.

What Measurement Techniques Can Be Used To Assess The Surface Finish Of Gears Produced On A Metal Lathe, And What Parameters Are Most Critical?To check how smooth gears are, we can use a few tools. One tool is a special microscope that looks closely at the gear’s surface. Another one is a machine called a profilometer, which measures bumps and dips on the gear. The most important things to look at are how smooth the surface is and if there are any scratches or marks. These help make the gears work better and last longer.