Have you ever wondered how factories make shiny, smooth metal parts? One crucial tool they use is the lathe. With a lathe, a skilled worker can shape and finish metal pieces perfectly.

Imagine holding a small metal part that fits just right in a machine. That smooth surface you feel is thanks to careful finishing on a lathe. But what exactly is lathe surface finish, and why does it matter?

Getting the right finish on metal lathe parts can make a huge difference. It affects how well they work together in machines. Plus, it makes the parts look great!

Join us as we explore the world of lathe surface finish. You’ll discover tips, tricks, and maybe even some surprising facts. Let’s dive in and learn more about how lathe skills help create amazing metal pieces!

Lathe Surface Finish: Enhancing Metal Lathe Parts Quality

Lathe Surface Finish: Key Insights for Metal Lathe Parts

Lathe surface finish makes a big difference in metal parts. A good finish not only looks better but also improves performance. Did you know that smoother surfaces can reduce friction? This means machinery runs more efficiently! Selecting the right tools and techniques can help achieve a high-quality surface. By understanding lathe surface finishes, you can enhance the durability and appearance of your projects. Are you ready to take your metalworking skills to the next level?Understanding Surface Finish in Metalworking

Definition and importance of surface finish in manufacturing. Key terms related to surface finish.In metalworking, surface finish is how smooth or rough a surface is after it is made. This quality matters because it affects how parts work and look. A smooth finish helps parts fit well and last longer. Here are some key terms related to surface finish:

- Roughness: The texture of a surface.

- Finish: The final look of a surface.

- Texture: How the surface feels.

Manufacturers aim for the best surface finish to improve the product’s performance and appearance.

What is the importance of surface finish in manufacturing?

Surface finish is crucial because it impacts product quality and functionality. For example, smoother surfaces reduce friction, while a rougher finish can improve adhesion in some cases. Better finishes lead to happier customers and fewer product failures.

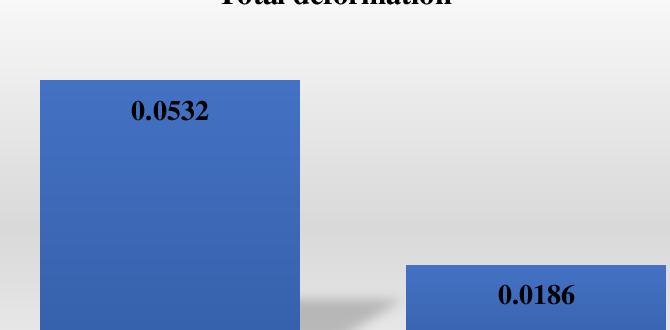

Factors Affecting Surface Finish in Lathe Operations

Impact of cutting tool materials and geometry. Role of machining parameters (speed, feed, depth of cut).Many things can change how smooth your lathe parts feel. First, the cutting tool material and its shape play a big role. For example, a sharp tool makes a better finish than a dull one. Now, let’s talk about the “machining parameters.” This fancy term includes speed, feed, and depth of cut. If you go too fast, you might create bumps on your metal. Finding the right balance is key! Remember: too much cutting depth? You might as well be ice skating on sandpaper!

| Factor | Impact on Surface Finish |

|---|---|

| Cutting Tool Material | A sharper tool leads to a smoother finish |

| Speed | High speed can create rough surfaces |

| Feed Rate | Faster feed may lead to a rougher finish |

| Depth of Cut | A deeper cut can lower quality |

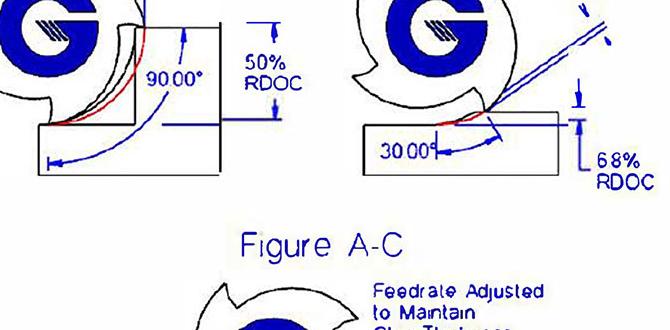

Techniques for Improving Surface Finish on Metal Lathe Parts

Best practices for tool selection and maintenance. Adjusting machining parameters for optimal results.To achieve a great surface finish on metal lathe parts, choosing the right tools is key. Sharp, high-quality tools work wonders! Regular maintenance is crucial too. A clean tool cuts better and lasts longer—like a happy puppy! Adjusting the speed and feed rate is necessary for the best results. Too fast? You might get a rough finish. Too slow? You could waste time!

| Machining Parameter | Effect on Surface Finish |

|---|---|

| Speed (RPM) | Faster speeds can lead to smoother surfaces. |

| Feed Rate | Lower rates often improve finish quality. |

Remember, even the fanciest machines need a little TLC! Adjust your settings to match the material, like tuning a guitar, and you’ll hit the perfect note every time.

Common Problems and Solutions for Surface Finish Issues

Identifying defects in surface finish (e.g., chatter, scratches). Troubleshooting methods to rectify surface finish problems.Every lathe operator faces surface finish challenges. Chatter is a common issue, making your part look like it danced with a jellyfish. Scratches can appear from dull tools, ruining your masterpiece. To fix these problems, check your tool sharpness and adjust spindle speed. A smooth operation is key! You can also adjust the feed rate to reduce vibrations. Here’s a quick troubleshooting guide:

| Problem | Solution |

|---|---|

| Chatter | Reduce spindle speed or adjust cutting feed |

| Scratches | Use sharp tools and clean the workpiece |

Case Studies: Successful Surface Finish Applications

Examples of industries achieving superior finishes. Lessons learned and applied practices from successful cases.Many industries are nailing it with their surface finishes. For example, the automotive sector loves shiny parts that reflect quality. They learned that using proper tools boosts the finish. In medicine, companies use smooth surfaces for devices. This reduces friction, making them safer. It’s like polishing your shoes before a big event! Below are some lessons and practices that helped:

| Industry | Success Factors |

|---|---|

| Automotive | Right tools, skilled workers |

| Medical | Smooth surfaces, better safety |

These cases show that investing time and effort can make a huge difference. Remember, a shiny part might just be the key to success!

Conclusion

In summary, lathe surface finish affects how metal parts look and work. A smooth finish improves performance and durability. You can achieve this by choosing the right tools and techniques. Explore different finishing methods to find what works best for your projects. Remember, practice makes perfect, so keep experimenting and learning! For more tips, check out our other articles.FAQs

Sure, Here Are Five Related Questions On The Topic Of Lathe Surface Finish For Metal Lathe Parts:Sure! When we use a lathe to make metal parts, the surface finish is very important. A good surface finish makes the part smooth and nice to touch. It helps the part work better and last longer. You can improve the surface finish by using the right tools and speeds. It’s like polishing your toys to make them shiny!

Sure! Please provide the question you want me to answer.

What Are The Primary Factors That Influence The Surface Finish Of Lathe-Turned Metal Parts?The surface finish of lathe-turned metal parts depends on a few important things. First, the type of tool we use can make the surface smooth or rough. Second, the speed of the lathe affects how well the metal gets cut. Finally, using the right kind of cutting fluid helps keep the metal cool and improves the finish. Keeping these factors in mind can help us create better parts!

How Do Different Cutting Tools And Materials Affect The Surface Finish Quality On A Lathe?Different cutting tools and materials can change how smooth or rough a surface looks after using a lathe. If you use a sharp tool, it makes a nicer finish. A dull tool can leave scratches and bumps. Some materials are softer and easier to cut, which helps in making a smoother surface. Choosing the right tool and material is very important for a good finish.

What Are The Recommended Cutting Speeds And Feeds For Achieving Optimal Surface Finish On Various Metals?To get a smooth finish on different metals, we need to use the right cutting speeds and feeds. For soft metals like aluminum, we can cut faster. For harder metals like steel, we should cut slower. A good starting speed is around 100 to 300 feet per minute. Always remember to adjust speeds for the type of metal you’re using!

What Post-Machining Processes Can Be Employed To Improve The Surface Finish Of Lathe-Turned Components?To make lathe-turned parts feel smooth, we can use a few methods. You can polish the surface with a cloth or special tools. We can also sand it to remove rough spots. Another way is to use a process called anodizing, which adds a protective layer. Finally, we can clean the part to remove any dust or dirt.

How Can One Measure The Surface Finish Of Machined Parts, And What Metrics Are Commonly Used?You can measure the surface finish of machined parts using tools like a roughness tester. This tool checks how smooth or rough a surface is. We often talk about two main metrics: Ra (average roughness) and Rz (average height of peaks and valleys). These numbers help us understand if the part is smooth enough for its job.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure, Here Are Five Related Questions On The Topic Of Lathe Surface Finish For Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we use a lathe to make metal parts, the surface finish is very important. A good surface finish makes the part smooth and nice to touch. It helps the part work better and last longer. You can improve the surface finish by using the right tools and speeds. It’s like polishing your toys to make them shiny!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Factors That Influence The Surface Finish Of Lathe-Turned Metal Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish of lathe-turned metal parts depends on a few important things. First, the type of tool we use can make the surface smooth or rough. Second, the speed of the lathe affects how well the metal gets cut. Finally, using the right kind of cutting fluid helps keep the metal cool and improves the finish. Keeping these factors in mind can help us create better parts!”}},{“@type”: “Question”,”name”: “How Do Different Cutting Tools And Materials Affect The Surface Finish Quality On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and materials can change how smooth or rough a surface looks after using a lathe. If you use a sharp tool, it makes a nicer finish. A dull tool can leave scratches and bumps. Some materials are softer and easier to cut, which helps in making a smoother surface. Choosing the right tool and material is very important for a good finish.”}},{“@type”: “Question”,”name”: “What Are The Recommended Cutting Speeds And Feeds For Achieving Optimal Surface Finish On Various Metals?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth finish on different metals, we need to use the right cutting speeds and feeds. For soft metals like aluminum, we can cut faster. For harder metals like steel, we should cut slower. A good starting speed is around 100 to 300 feet per minute. Always remember to adjust speeds for the type of metal you’re using!”}},{“@type”: “Question”,”name”: “What Post-Machining Processes Can Be Employed To Improve The Surface Finish Of Lathe-Turned Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make lathe-turned parts feel smooth, we can use a few methods. You can polish the surface with a cloth or special tools. We can also sand it to remove rough spots. Another way is to use a process called anodizing, which adds a protective layer. Finally, we can clean the part to remove any dust or dirt.”}},{“@type”: “Question”,”name”: “How Can One Measure The Surface Finish Of Machined Parts, And What Metrics Are Commonly Used?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can measure the surface finish of machined parts using tools like a roughness tester. This tool checks how smooth or rough a surface is. We often talk about two main metrics: Ra (average roughness) and Rz (average height of peaks and valleys). These numbers help us understand if the part is smooth enough for its job.”}}]}