Have you ever wondered how smooth and shiny metal parts are made? It often comes down to the amazing tools used in metalworking. Among these, lathe surface finish can make a big difference in quality and appearance. When using metal lathe tools, achieving the perfect finish is both an art and a science.

Imagine you are working on a project. You want your metal piece to gleam like a new car. But how do you get there? That’s where understanding lathe surface finish comes into play. With the right techniques and tools, you can create stunning results.

Did you know that the finish on a metal surface can affect its performance? A smoother finish can lead to better function and longer-lasting parts. That’s why everyone from hobbyists to seasoned professionals cares about their lathe tools. They know that a good finish is key to success.

In this article, we will dive deeper into lathe surface finishes. You’ll learn about various metal lathe tools, tips for a smooth finish, and much more. Get ready to unlock the secrets of perfect metalworking!

Lathe Surface Finish: Enhancing Metal Lathe Tools Performance

Lathe Surface Finish with Metal Lathe Tools

Lathe surface finish is crucial for creating smooth, polished metal parts. Using metal lathe tools effectively can enhance the quality of your work. Did you know that a well-finished surface reduces friction and wear? It can also improve the lifespan of your projects! Understanding factors like cutting speed and tool material helps achieve better results. With the right techniques, you can make your lathe work shine, leading to impressive creations.Understanding Surface Finish in Metalworking

Definition and importance of surface finish. Common measurements and classifications of surface finish.Surface finish is like the icing on a cake—it makes things look nice and feel smooth. In metalworking, the surface finish matters because it affects how parts work and fit together. A good finish can prevent friction and wear, kind of like butter on hot toast! Common ways to measure surface finish include Ra (average roughness) and Rz (average peak to valley height). Understanding these measurements helps you pick the right tools for the job. Below is a table showing some common classifications:

| Measurement | Meaning |

|---|---|

| Ra | Average roughness |

| Rz | Average height of peaks and valleys |

| Rt | Total height of the surface profile |

Types of Surface Finishes with Metal Lathes

Glossy vs. matte finishes. Comparisons of various surface finish techniques.Different surface finishes can change how metal looks and feels. Some finishes give a shiny, glossy look, while others are matte and soft. Each type has its advantages.

- Glossy Finish: Smooth and reflective, often used for style.

- Matte Finish: Dull and smooth, can hide fingerprints better.

Some techniques used to create these finishes include polishing, sanding, and coating. Comparing these methods helps you choose the best one for your project.

What is the difference between glossy and matte finishes?

Glossy finishes are shiny and reflect light, while matte finishes are dull and do not reflect much light. This affects both appearance and how smudges show.

Which surface finish is better for metal lathe tools?

It depends on your project needs. Glossy may be best for looks, while matte can be better for grip and usage. Always consider your task before deciding!

Key Factors Affecting Surface Finish

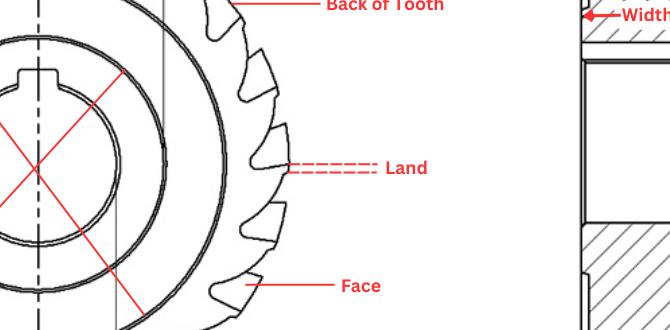

Tool material and geometry. Cutting speed and feed rate considerations.Several key factors decide the quality of surface finish in metal lathe work. The material and shape of the tool play a big role. Harder materials make better cuts. The geometry of the tool affects how the metal is shaped. Cutting speed and feed rate also matter. Too fast or slow can ruin the finish. Here are some points to consider:

- Tool Material: Use harder tools for lasting sharpness.

- Tool Geometry: Shapes that cut smoothly yield better finishes.

- Cutting Speed: Find the right speed for the metal being worked on.

- Feed Rate: A balanced rate leads to less chatter and a smoother finish.

What affects surface finish quality?

Tool material, geometry, cutting speed, and feed rate significantly impact surface finish quality.Best Practices for Optimal Surface Finish Using Lathe Tools

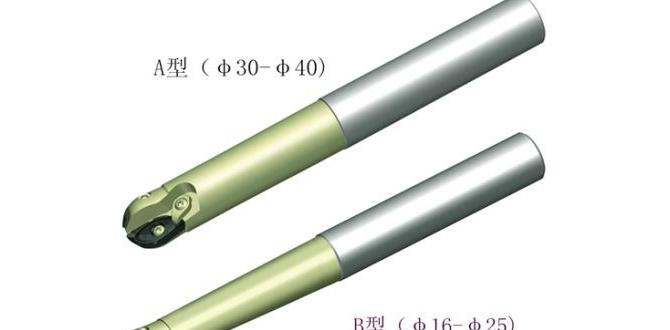

Selecting the right tool for the job. Techniques to minimize vibration and chatter.Choosing the right tool is like picking the best ice cream flavor—everyone has their favorite! For a smooth metal surface, go for tools made specifically for your lathe. Make sure they match the material you’re working with. High-speed steel or carbide tools often do the trick!

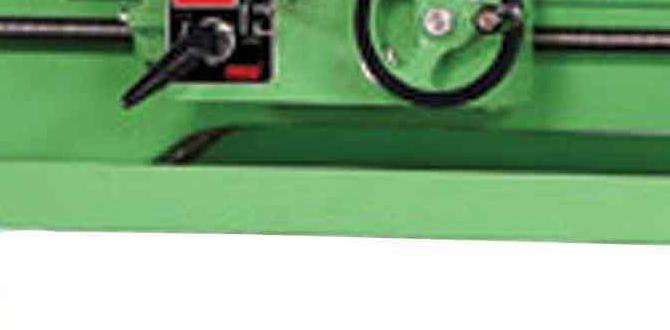

Next up, let’s tackle the pesky problem of vibration and chatter. Keep your lathe machine sturdy. Adding weights can help reduce the wiggles! Check your cutting speed too; going too fast can make your lathe dance. Remember, nobody likes a bumpy ride, not even your metal!

| Tool Type | Best For |

|---|---|

| High-Speed Steel | Soft metals |

| Carbide | Hard metals |

Common Problems and Solutions for Surface Finish Issues

Identifying causes of poor surface finish. Troubleshooting tips to improve results.Sometimes, getting a shiny surface can feel like trying to find a unicorn! Poor surface finish can come from a few sneaky issues. First, dull tools can mess things up. Second, incorrect speed settings might make things rough. Lastly, the material itself may fight back. To solve these problems, sharpen those tools and check your settings. A little twist here and there often works wonders!

| Problem | Solution |

|---|---|

| Dull tools | Sharpen or replace them |

| Wrong speed settings | Adjust RPM for smoother cuts |

| Material issues | Choose a different type or test bits |

With these tips, you’ll be on your way to snagging that shiny finish. Just remember, it takes some practice, like baking a cake without burning it—unless you enjoy cake that way!

Advanced Techniques for Enhanced Surface Finish

Use of coatings and finishes postturning. Innovative lathe settings and tools for superior results.Getting that shiny finish on your metalwork can be like polishing your grandma’s silverware — it takes some technique! Coatings and finishes after turning can help. Think of it like sprucing up before the big party. Using special waxes or paints can make your creations look slick. Plus, with innovative lathe settings and tools, your projects will outshine the competition. Always remember: a great finish can make the difference between “Wow!” and “Eh.”

| Technique | Benefit |

|---|---|

| Coatings | Protective layer that prevents rust! |

| Innovative Tools | Better precision for a smoother result! |

Case Studies: Successful Surface Finish Projects

Examples of projects that highlight effective surface finish. Lessons learned and best practices from realworld applications.Many projects show how great surface finish can be. One project used metal lathe tools to create smooth parts for a car engine. They learned that good planning saves time.

Here are some lessons from successful projects:

- Choose the right tools for the job.

- Test different speeds and feeds for the best results.

- Keep the workspace clean for safety.

One quote says, “Success is in the details.” Each detail counts toward a perfect finish! By learning from these examples, anyone can improve their surface finishing skills.

What are some effective surface finish projects?

Effective surface finish projects highlight planning and correct tool use. Examples include automotive parts, custom fixtures, and even art sculptures. Each project teaches valuable lessons about achieving smooth and polished results.

Future Trends in Metal Lathe Surface Finishing

Emerging technologies in lathe tools. Sustainable practices in achieving surface finishes.The future of finishing metal surfaces looks bright with new technologies on the way. Smart machines are becoming common in metal lathes. These tools can adjust settings automatically for better finishes. Also, green practices are gaining popularity. Many companies focus on recycling materials and reducing waste. This helps keep our planet healthy.

- 3D printing for custom tools

- Water-based coolants to reduce pollution

- AI to enhance precision

What sustainable practices are emerging in metal lathe finishing?

Companies are using eco-friendly materials and recycling waste. They also aim to cut down on energy use. This creates products that don’t harm the Earth.

Conclusion

In summary, lathe surface finish is crucial for high-quality metal work. Using the right lathe tools improves the smoothness of your projects. Remember to pick tools that match your needs. You can experiment with different techniques to see what works best for you. For more tips on lathe tools and finishing, check out beginner guides online!FAQs

What Factors Influence The Surface Finish Quality When Using A Metal Lathe?When we use a metal lathe, several things affect how smooth the finished metal surface is. First, the kind of tool we use matters; sharp tools make better finishes. Next, the speed at which we spin the metal can change the surface too. If we use the right feed rate, or how fast the tool moves, it gives a nicer look. Finally, keeping everything clean and well-oiled helps make the surface shiny and smooth.

How Do Different Lathe Tool Materials And Coatings Affect The Surface Finish Of Machined Parts?Different lathe tool materials, like steel or carbide, can change how smooth a part feels. Carbide tools last longer and cut better, giving a nicer finish. Coatings, like titanium or ceramic, help tools slide better and stay sharper. When tools work well, they leave fewer marks on the surface. This makes our final product look and feel great!

What Is The Importance Of Spindle Speed And Feed Rate In Achieving Desired Surface Finish On A Lathe?Spindle speed is how fast the lathe’s spinning part goes. A good speed helps make smooth surfaces. Feed rate is how quickly the cutting tool moves across the material. If we choose the right feed rate and spindle speed, we get a nice, shiny finish. It’s all about balance to make our work look great!

How Can The Selection Of Cutting Fluids Impact The Surface Finish During Lathe Operations?Choosing the right cutting fluid helps keep the tool cool and clean. When we use good cutting fluids, they reduce friction. This makes the metal surface smooth and shiny. If we pick the wrong fluid, the finish can be rough and uneven. So, we need to think carefully about our choice!

What Techniques Can Be Employed To Improve Surface Finish On Metal Lathe-Machined Components?To make metal parts smoother after using a lathe, you can try a few things. First, use sharper cutting tools. This will help cut the metal cleanly. Second, adjust the speed of the lathe; going slower can create a nicer finish. You can also add oil or lubricant to reduce friction and help the tool work better. Finally, sanding or polishing the finished part can make it shine!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Using A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a metal lathe, several things affect how smooth the finished metal surface is. First, the kind of tool we use matters; sharp tools make better finishes. Next, the speed at which we spin the metal can change the surface too. If we use the right feed rate, or how fast the tool moves, it gives a nicer look. Finally, keeping everything clean and well-oiled helps make the surface shiny and smooth.”}},{“@type”: “Question”,”name”: “How Do Different Lathe Tool Materials And Coatings Affect The Surface Finish Of Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe tool materials, like steel or carbide, can change how smooth a part feels. Carbide tools last longer and cut better, giving a nicer finish. Coatings, like titanium or ceramic, help tools slide better and stay sharper. When tools work well, they leave fewer marks on the surface. This makes our final product look and feel great!”}},{“@type”: “Question”,”name”: “What Is The Importance Of Spindle Speed And Feed Rate In Achieving Desired Surface Finish On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the lathe’s spinning part goes. A good speed helps make smooth surfaces. Feed rate is how quickly the cutting tool moves across the material. If we choose the right feed rate and spindle speed, we get a nice, shiny finish. It’s all about balance to make our work look great!”}},{“@type”: “Question”,”name”: “How Can The Selection Of Cutting Fluids Impact The Surface Finish During Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right cutting fluid helps keep the tool cool and clean. When we use good cutting fluids, they reduce friction. This makes the metal surface smooth and shiny. If we pick the wrong fluid, the finish can be rough and uneven. So, we need to think carefully about our choice!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Improve Surface Finish On Metal Lathe-Machined Components? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make metal parts smoother after using a lathe, you can try a few things. First, use sharper cutting tools. This will help cut the metal cleanly. Second, adjust the speed of the lathe; going slower can create a nicer finish. You can also add oil or lubricant to reduce friction and help the tool work better. Finally, sanding or polishing the finished part can make it shine!”}}]}