Have you ever used a lathe and noticed a strange problem with the tailstock? It can be quite frustrating when the tailstock binds and doesn’t move smoothly. Many woodworkers and metalworkers face this issue at some point. But don’t worry! There are simple ways to fix it.

Imagine you’re in the middle of a project. You’re excited, but suddenly the tailstock refuses to budge. Could there be something stuck? Or maybe it’s out of alignment? Understanding how to tackle lathe tailstock binding can save your project and restore your peace of mind.

Here’s a fun fact: many beginners face this issue, and it’s often easy to fix! This article will explore different ways to identify the problem and how to solve it quickly. With the right tips, you’ll be back at your work in no time, enjoying the smooth operation of your lathe.

Lathe Tailstock Binding Fix: Solutions And Tips For Smooth Use

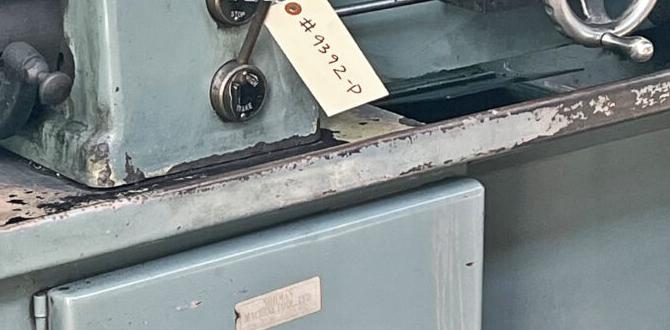

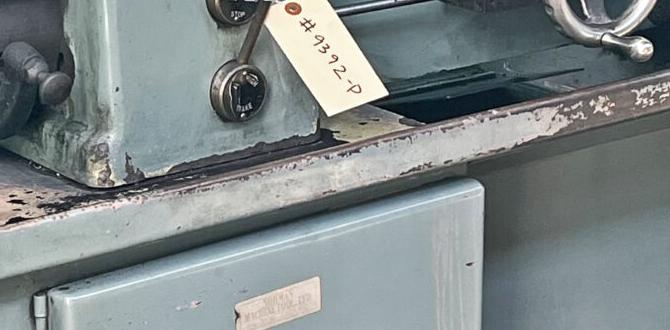

Lathe Tailstock Binding Fix

Lathe tailstock binding can be frustrating for woodworkers and metalworkers alike. It occurs when the tailstock doesn’t move smoothly along the bed. You can fix this with a few simple steps. First, check for debris or rust that might cause sticking. Regular cleaning and lubrication can help. Did you know that a little wax on the bed can create a smoother glide? This easy trick can save you time and improve your work quality!Understanding Lathe Tailstock Binding

Definition of tailstock binding and its implications on lathe operation.. Common causes of tailstock binding in lathes..Lathe tailstock binding happens when the tailstock does not move smoothly on the lathe. This issue can slow down your work and make it hard to get accurate results. Common causes include dirt or debris stuck in the tailstock, misalignment, and worn parts. If left unchecked, binding can affect your projects and damage the lathe.

- Dirt and debris can block movement.

- Misalignment can occur from poor setup.

- Worn parts can lead to loose fittings.

What are signs of tailstock binding?

Common signs include difficulty moving the tailstock, uneven cuts, and unusual noises while operating.

Identifying Symptoms of Tailstock Binding

Signs that indicate tailstock binding is occurring during use.. How to differentiate between minor issues and serious binding problems..Tailstock binding can throw a wrench in your woodworking plans. Watch out for these signs: difficulty moving the tailstock, unexpected jerks, or a rough feeling when adjusting. If your materials are getting stuck like they’re having a tough day, it might be time to investigate. Minor issues can be fixed easily, while serious binding can lead to major headaches—or worse, safety hazards! Comparing these symptoms can help:

| Symptoms | Minor Issues | Serious Problems |

|---|---|---|

| Sticking | Adjustable with slight pressure | Requires force to move |

| Noise | Soft squeaks | Loud grinding sounds |

| Movement | Runs smoothly after adjustment | Consistent blockage |

Being aware of these signs can save you time and effort. Don’t let tailstock binding bind you up!

Tools and Materials Needed for Fixing Tailstock Binding

List of essential tools required for diagnosing and fixing the issue.. Recommended materials and lubricants for maintenance..Fixing tailstock binding is easier with the right tools and materials. You need essential tools to diagnose and solve the issue effectively. Here’s what you should gather:

- Wrenches

- Screwdrivers

- Lubricating oil

- Wood clamps

- Cleaning rags

Also, using recommended lubricants helps maintain smooth operation. Proper care can prevent future problems. Consider using:

- Light machine oil

- Grease

What tools do I need for fixing tailstock binding?

You need wrenches, screwdrivers, and lubricating oil for fixing tailstock binding. These tools help identify and solve issues quickly.

Step-by-Step Guide to Fix Lathe Tailstock Binding

Detailed instructions on inspecting the tailstock for damages or misalignments.. Methods for cleaning and lubricating the tailstock mechanism..First, check the tailstock for any visible damages or parts that seem out of place. Look closely for scratches, dents, or anything that feels off. A crooked tailstock is like a pizza with the toppings sliding off—no one wants that!

Next, it’s time to clean the mechanism. Grab a soft cloth and some lubricant. Wipe away dust and grime. Apply the lubricant to smooth out any stiffness. Think of it as putting butter on toast—everything moves better when it’s slick!

| Step | Action |

|---|---|

| 1 | Inspect for damages |

| 2 | Clean the tailstock |

| 3 | Lubricate for smoothness |

Following these steps will help ensure your lathe runs smoothly. As they say, “A happy tailstock makes for a happy workshop!”

Adjusting the Tailstock Alignment

Techniques for ensuring proper alignment of the tailstock.. Importance of checking alignment regularly to prevent binding..Keeping your lathe tailstock aligned is vital for smooth operation. A misaligned tailstock can lead to binding, which is about as fun as stepping on a Lego! Checking alignment regularly prevents these annoying surprises. Use the following techniques to ensure proper alignment:

| Technique | Description |

|---|---|

| Visual Check | Look at the tailstock and the spindle. They should be straight like an arrow. |

| Digital Indicators | Use them to measure alignment. It’s like having a high-tech ruler! |

| Adjustments | Tighten or loosen screws to fix any misalignment. Think of it as giving your lathe a gentle hug. |

By performing these checks often, you can avoid the headache of binding. Remember, a happy lathe means more time for your creative projects. And who doesn’t want that?

Preventative Measures to Avoid Future Binding

Best practices for regular maintenance of the lathe tailstock.. Tips for safe operating procedures to minimize wear and tear..Keeping your lathe tailstock in shape is like brushing your teeth—skip it, and things get messy! Regularly check for dust and grime. Even a tiny speck can cause binding. Lubricate moving parts often; a little oil goes a long way. Always use the right tools, and remember to handle the tailstock gently. Treat it like a precious pizza—no need to toss it around! Here are a few best practices:

| Maintenance Tip | Frequency |

|---|---|

| Clean Dust and Dirt | After Every Use |

| Lubricate Moving Parts | Weekly |

| Inspect for Damage | Monthly |

By following these tips, you can keep your lathe tailstock happy and avoid future binding. Who knew machine care could be this fun?

When to Seek Professional Help

Signs that indicate a more complex issue requiring expert intervention.. How to choose a qualified technician for lathe repairs..It’s important to know when to get help with a lathe. If your tailstock binds or won’t move, it might be a sign of a bigger problem. Other signs include strange noises or uneven cutting. If you notice these, don’t hesitate. Professional help can fix issues faster than you!

To choose a good technician, look for these points:

- Experience with lathes

- Positive reviews from others

- Clear pricing and good communication

How do I know if I need help for my lathe?

If you see signs like binding, strange sounds, or uneven cuts, call an expert.

Conclusion

In summary, fixing a lathe tailstock binding requires careful adjustment and lubrication. Always check for debris or misalignment first. You can improve your lathe’s performance by regularly maintaining it. If you want to learn more, consider reading manuals or watching tutorials online. By staying proactive, you can keep your lathe running smoothly and enjoy your woodworking projects even more!FAQs

What Are The Common Causes Of Binding In A Lathe Tailstock, And How Can They Be Identified?Binding in a lathe tailstock can happen for a few reasons. It might be caused by dirt or debris stuck inside. Sometimes, parts might be too tight or misaligned. You can check for binding by moving the tailstock back and forth. If it feels sticky or hard to move, that’s a sign something is wrong.

What Step-By-Step Process Should Be Followed To Diagnose And Fix Tailstock Binding Issues?To fix tailstock binding issues, follow these steps. First, check if the tailstock moves freely. If it’s stuck, clean the area around it. Next, look for any loose screws or parts. Tighten them if needed. Finally, test the tailstock again to see if it works smoothly. If it still binds, ask an adult for help.

How Can The Lubrication And Maintenance Of The Tailstock Prevent Binding Problems?Lubricating and maintaining the tailstock helps it move smoothly. When we add oil, it reduces friction, which means less sticking. If we keep it clean and check for dirt, it won’t get stuck. Regular checks make sure everything fits well. This way, we prevent binding problems and our work is easier.

What Tools Are Recommended For Adjusting The Tailstock Alignment To Alleviate Binding?To fix the tailstock alignment, you can use a few simple tools. A straight edge helps check if everything is lined up. You can also use a feeler gauge to measure small gaps. A wrench is good for loosening and tightening screws. With these tools, you can make your machine work smoothly!

When Should A Lathe Operator Consider Replacing The Tailstock Vs. Performing Repairs To Fix Binding Issues?You should think about replacing the tailstock if repairs don’t fix the binding problems. If the tailstock is old, cracked, or worn out, replacing it might be best. Repairs can work well for small issues, like dirt or minor damage. But if it keeps binding after fixing, a new tailstock can help you work better.