Have you ever struggled with a tailstock that won’t stay in place? If so, you’re not alone. Many woodworkers and machinists face this common issue with their lathe tailstocks. The tailstock cam lock is a key part that helps keep everything tight and secure. When it fails, it can ruin your project and waste time.

Fixing a lathe tailstock cam lock might sound tricky. But don’t worry! Many simple solutions can help you get back to work quickly. Here’s a fun fact: many people don’t realize that a loose tailstock can lead to dangerous accidents if not addressed.

In this article, we will explore easy ways to fix your lathe tailstock cam lock. You’ll discover tips that anyone can follow, even if you’re new to woodworking. Ready to learn how to keep your equipment in top shape?

Lathe Tailstock Cam Lock Fix: A Comprehensive Guide

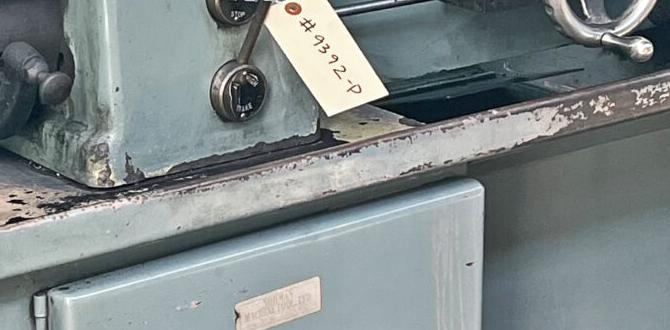

Lathe Tailstock Cam Lock Fix

Fixing a lathe tailstock cam lock can seem tricky. This handy tool is key for keeping your work steady. When it malfunctions, it can cause frustration. A common issue is wear or damage to the cam lock mechanism. Luckily, you can often fix it with simple tools. Regular maintenance helps prevent these issues. Did you know that keeping your lathe clean can extend its life? Understanding this process can save you time and money!Understanding Lathe Tailstock Mechanism

Explanation of the tailstock’s role in lathe operation. Components involved in the tailstock assembly.The tailstock is like the trusty sidekick of a lathe. It helps support the other end of the piece you are working on. This support allows for precise shaping and drilling. A few key components help it do its job: the tailstock body, quill, and locking mechanisms. The quill slides in and out, while the lock keeps everything steady. Without these parts, you might end up with an oddly shaped mess instead of a perfect project!

| Component | Function |

|---|---|

| Tailstock Body | Holds the whole assembly together. |

| Quill | Makes adjustments and supports the tool. |

| Locking Mechanism | Keeps everything tightly in place. |

Common Issues with Tailstock Cam Locks

Symptoms indicating a cam lock malfunction. Causes of cam lock failure.Have you noticed your tailstock is acting a bit wobbly? That’s a sign of cam lock trouble! Common symptoms include the tailstock not locking properly or slipping during use. These issues can happen for a few reasons. It might be due to wear and tear or dirt clogging the mechanism. Sometimes, the parts are just too loose, like that last piece of spaghetti in the pot!

| Symptom | Possible Cause |

|---|---|

| Slipping Tailstock | Worn-out cam lock |

| Inability to Lock | Accumulated debris |

| Difficulty Adjusting | Loose components |

Identifying these signs early can save you a lot of trouble (and many angry tool faces!). Keep an eye out, and your lathe will thank you with smooth operations.

Step-by-Step Diagnosis of Cam Lock Problems

Visual inspection techniques. How to test functionality of the cam lock.Checking the cam lock on a lathe tailstock is simple. Start by looking closely for any cracks or dirt. Next, test the lock’s function. To do this, follow these tips:

- Turn the knob. Does it move freely?

- Lock it. Does it stay in place?

- Unlock it. Does it release easily?

If something feels wrong, it may need a fix. Regular checks help prevent bigger problems!

How do I know if my cam lock is working?

To check, ensure it locks tightly and releases smoothly. If not, consider adjustments or repairs.

Essential Tools for Fixing Tailstock Cam Locks

Recommended tools for tailstock repair. Safety equipment and precautions. “`htmlTo tackle the tailstock cam lock challenge, having the right tools is crucial. First, grab a wrench and some adjustable pliers to get those stubborn parts moving. You’ll also need a screwdriver set because small screws love to hide! Don’t forget your trusty hammer—it’s great for gentle persuasion. Safety comes first, so wear gloves and goggles. And remember, no one wants a surprise trip to the emergency room just because a screw wouldn’t budge!

| Tool | Purpose |

|---|---|

| Wrench | Loosens nuts and bolts |

| Screwdriver set | Turns screws |

| Pliers | Grabs and twists |

| Hammer | Helps with stubborn parts |

With these tools in hand, you’re on your way to fixing that tailstock cam lock. Just remember to keep it fun—who knew fixing stuff could be such a hoot?

“`DIY Fix for Lathe Tailstock Cam Lock

Detailed repair procedure. Tips for ensuring a proper fix.Fixing a lathe tailstock cam lock is easy if you follow a few steps. First, gather your tools: a wrench, a screwdriver, and some lubricating oil. Start by loosening the cam lock. Remove any old parts that are worn out. Clean the area to remove dirt and debris. Then, insert the new parts and tighten everything carefully.

To ensure a good fix, keep these tips in mind:

- Double-check all screws and bolts.

- Use oil to ensure smooth movement.

- Test the lock before starting your work.

Your lathe will run better with a properly fixed tailstock cam lock.

How do I know if my cam lock needs repair?

Look for signs like the lock being hard to turn or not holding securely. If it slips or feels loose, it’s time for a fix.

Preventative Maintenance for Tailstock Longevity

Regular maintenance tips to prevent future issues. Lubrication and cleaning recommendations.Taking care of your tailstock can save you a lot of headaches later on. Regular checks help spot problems before they become big issues. Keep things clean and tidy. Dust and grime can cause parts to stick or wear out faster. Lubrication is key! Apply the right oil to moving parts every few weeks to keep everything smooth. Think of it as giving your lathe a nice spa day!

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Clean Tailstock | Weekly | Use a soft cloth or brush. |

| Lubricate Moving Parts | Every 2-4 weeks | Apply light oil, not too much! |

| Check for Loose Parts | Monthly | Tighten screws but don’t overdo it! |

Remember, a happy lathe means a happy maker. Like they say, “A stitch in time saves nine”—or in this case, a little maintenance saves you from a big mess!

When to Seek Professional Help

Signs that indicate the need for expert assistance. Benefits of professional repair services.Having trouble with your lathe? It might be time to call in a pro! If you see signs like unusual noises or difficulty locking the tailstock, don’t ignore them. These could signal bigger problems. Getting expert help means your lathe gets fixed right the first time. Plus, pros often have the magic tools and knowledge to solve issues quickly. Remember, a well-fixed lathe is a happy lathe!

| Signs You Need Help | Benefits of Professional Repair |

|---|---|

| Unusual noises | Quick and accurate repairs |

| Difficulty adjusting | Expert knowledge |

| If it stops working | Tools you might not have |

Real-Life Case Studies and Solutions

Examples of common tailstock issues faced by users. Successful fixes and lessons learned from these cases.Users often face tailstock problems on lathes. Some common issues include stuck tailstocks, misalignment, and difficulty locking. For example, one user found their tailstock wouldn’t move at all. After cleaning the parts and adjusting the cam lock, it worked smoothly again. Another case involved a misaligned tailstock, causing uneven cuts. The solution was a quick adjustment and careful measurements. Each experience teaches us valuable lessons about maintenance and care.

What are common tailstock problems and how can they be fixed?

Common tailstock issues can hamper your work. Here are some solutions:

- Stuck Tailstock: Clean and lubricate the parts.

- Misalignment: Adjust the tailstock position accurately.

- Difficulty Locking: Inspect the cam lock for wear and tear.

Conclusion

In summary, fixing a lathe tailstock cam lock can improve your lathe’s performance. Check for wear and tear, clean the components, and adjust the locks. You can also replace damaged parts when needed. Follow these steps to keep your lathe running smoothly. For more detailed guidance, look for online tutorials or manuals. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tailstock Cam Lock Fixes:Sure! Here are five questions about fixing the lathe tailstock cam lock. 1. What is a lathe tailstock cam lock? 2. Why is my lathe tailstock cam lock not working? 3. How can I tighten the tailstock cam lock? 4. What’s a simple way to fix a loose lock? 5. Where can I find replacement parts for my cam lock? Let me know if you need help answering these!

Sure! Please provide me with the question you’d like me to answer.

What Are The Common Symptoms Of A Malfunctioning Lathe Tailstock Cam Lock?If the lathe tailstock cam lock isn’t working well, you might notice a few things. First, the tailstock may not stay locked in place. You could also see it moving while you’re trying to work. Sometimes, it can be hard to turn the handle. Lastly, it may make strange noises when you try to lock it.

How Can I Adjust The Tailstock Cam Lock For Improved Accuracy On My Lathe?To adjust the tailstock cam lock on your lathe, first, make sure the tailstock is in the right place. Then, loosen the lock slightly. Turn the adjusting screw until the tailstock fits snugly without wobbling. Finally, tighten the lock back up. Check to see if it holds nicely and stays in place while you work.

What Tools And Materials Are Necessary To Repair A Lathe Tailstock Cam Lock?To repair a lathe tailstock cam lock, you need a few tools. First, grab a wrench to loosen the bolts. Next, you’ll need a screwdriver to remove any screws. You might also need replacement parts like a new spring or a cam lock. Lastly, have a clean cloth to wipe away dirt and grease.

Are There Any Preventative Maintenance Steps To Prolong The Life Of A Tailstock Cam Lock On A Lathe?Yes, we can take some easy steps to keep the tailstock cam lock on a lathe working well. First, keep it clean by wiping away dust and grease. Next, check for any rust and remove it if you find any. We should also apply a little oil to keep the parts moving smoothly. Lastly, be gentle when using the cam lock to avoid breaking it.

How Can I Identify When A Tailstock Cam Lock Needs Replacement Rather Than Repair?You can tell if a tailstock cam lock needs replacing if it’s very hard to turn or doesn’t hold tight. Check if any parts look broken or worn down. If you see cracks or rust, it’s time to replace it. If the lock wiggles and keeps coming loose, that’s another sign. If the lock can’t be fixed easily, it’s better to get a new one.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tailstock Cam Lock Fixes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about fixing the lathe tailstock cam lock. 1. What is a lathe tailstock cam lock? 2. Why is my lathe tailstock cam lock not working? 3. How can I tighten the tailstock cam lock? 4. What’s a simple way to fix a loose lock? 5. Where can I find replacement parts for my cam lock? Let me know if you need help answering these!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Symptoms Of A Malfunctioning Lathe Tailstock Cam Lock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe tailstock cam lock isn’t working well, you might notice a few things. First, the tailstock may not stay locked in place. You could also see it moving while you’re trying to work. Sometimes, it can be hard to turn the handle. Lastly, it may make strange noises when you try to lock it.”}},{“@type”: “Question”,”name”: “How Can I Adjust The Tailstock Cam Lock For Improved Accuracy On My Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock cam lock on your lathe, first, make sure the tailstock is in the right place. Then, loosen the lock slightly. Turn the adjusting screw until the tailstock fits snugly without wobbling. Finally, tighten the lock back up. Check to see if it holds nicely and stays in place while you work.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Necessary To Repair A Lathe Tailstock Cam Lock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To repair a lathe tailstock cam lock, you need a few tools. First, grab a wrench to loosen the bolts. Next, you’ll need a screwdriver to remove any screws. You might also need replacement parts like a new spring or a cam lock. Lastly, have a clean cloth to wipe away dirt and grease.”}},{“@type”: “Question”,”name”: “Are There Any Preventative Maintenance Steps To Prolong The Life Of A Tailstock Cam Lock On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we can take some easy steps to keep the tailstock cam lock on a lathe working well. First, keep it clean by wiping away dust and grease. Next, check for any rust and remove it if you find any. We should also apply a little oil to keep the parts moving smoothly. Lastly, be gentle when using the cam lock to avoid breaking it.”}},{“@type”: “Question”,”name”: “How Can I Identify When A Tailstock Cam Lock Needs Replacement Rather Than Repair?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if a tailstock cam lock needs replacing if it’s very hard to turn or doesn’t hold tight. Check if any parts look broken or worn down. If you see cracks or rust, it’s time to replace it. If the lock wiggles and keeps coming loose, that’s another sign. If the lock can’t be fixed easily, it’s better to get a new one.”}}]}