Have you ever struggled to get a perfect hole when using a lathe? You’re not alone! Many beginners face this challenge, especially with the tailstock. Mastering lathe tailstock center drilling can make a big difference in your work.

Imagine how satisfying it feels to see a clean and precise hole. With the right tips, you can achieve that every time. Here’s a fun fact: even experienced woodworkers sometimes overlook the tailstock’s potential.

This article will share valuable tips to improve your center drilling skills. You’ll discover simple techniques that can boost your confidence and accuracy. Let’s dive in and explore how to make your lathe work smarter, not harder!

Lathe Tailstock Center Drilling Tips For Precision Work

Lathe Tailstock Center Drilling Tips

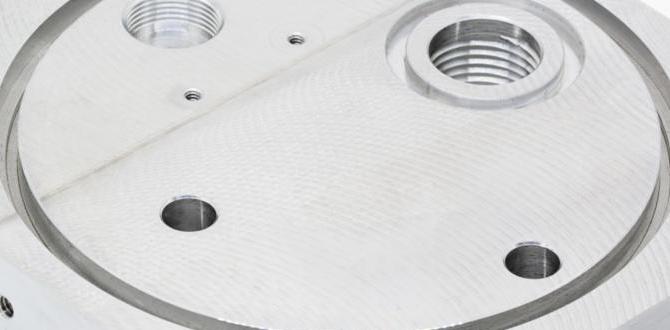

Understanding lathe tailstock center drilling can boost your skills. Always align the tailstock properly to avoid wobbly holes. Did you know that using a good drill bit can make a huge difference? It helps in creating clean, precise holes. Don’t forget to adjust the speed according to the material you’re working with. Keep your tools sharp; it’s safer and saves time. With these tips, you’ll master center drilling in no time!Understanding the Lathe Tailstock

Function and importance of the tailstock in lathe operations. Key components of the tailstock and their roles.A lathe tailstock is essential for holding workpieces steady while machining. It gives support and control during processes like drilling and boring. Think of it as a trusty sidekick for the lathe—keeping everything in place! Key parts include the spindle, which holds the drill bits, and the quill, which moves in and out for adjusting depth. Without these, your projects would go off the rails faster than a runaway train!

| Component | Role |

|---|---|

| Spindle | Holds drill bits securely |

| Quill | Moves in/out for depth control |

Choosing the Right Center Drill

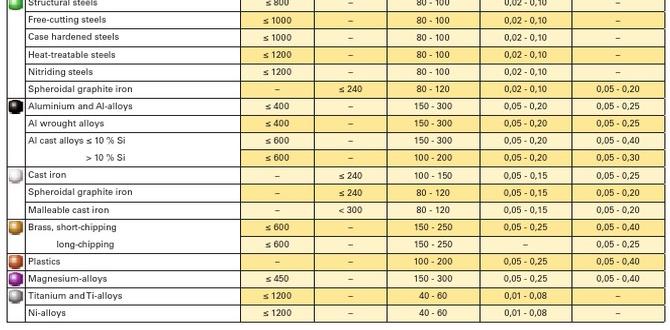

Different types of center drills and their specific applications. Factors to consider when selecting a center drill for tailstock use.Choosing the right center drill for lathe tailstock is important. There are different types available. Each type has its own uses. For example, stubby center drills are good for small projects. Longer center drills work well for deeper holes. Consider these factors when selecting:

- Size: Match the drill size to your workpiece.

- Material: Use the right material for your project, such as high-speed steel or carbide.

- Length: Choose a length that fits in your tailstock.

This will ensure better accuracy and results!

What are the types of center drills?

There are two main types: short and long. Short drills are best for shallow holes, while long drills reach deeper areas.

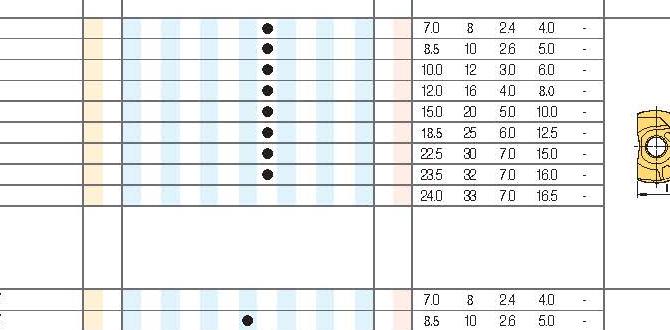

Setup Techniques for Accurate Center Drilling

How to properly align the workpiece with the tailstock. Adjusting tailstock position for optimal drilling.To achieve perfect center drilling, start with a steady workpiece—like your favorite snack on a flat surface! Align it with the tailstock, keeping everything in line. Adjust the tailstock position by sliding it until it meets your workpiece snugly. This helps in drilling straight. Remember, a tailstock that’s too far back is like a cat avoiding a bath—no good! Check your alignment regularly for accuracy.

| Step | Tip |

|---|---|

| 1 | Check alignment with the tailstock. |

| 2 | Slide the tailstock for optimal position. |

| 3 | Regularly verify your setup. |

Common Mistakes to Avoid in Center Drilling

Identifying frequent errors made by beginners. Tips for correcting misalignment and improper depth.Many beginners make common mistakes during center drilling. Misalignment is a big issue. If the drill isn’t straight, it will not create a good hole. Another mistake is drilling too deep or too shallow. This can ruin the piece. Here are tips to avoid these errors:

- Always check that your drill is lined up straight.

- Measure depths carefully before starting.

- Practice on scrap materials first.

Learning from mistakes will help you improve your skills.

What are the common mistakes in center drilling?

Common mistakes include misalignment and incorrect depths. These can lead to poor quality holes and damaged materials. Always verify your setup to avoid these issues.

Enhancing Precision with Tailstock Adjustments

Utilizing tailstock adjustments for finetuning drilling accuracy. Techniques for maintaining consistent depth when drilling.Adjusting the tailstock can help improve your drilling accuracy. Start by aligning it properly. This helps the drill go straight. To keep the depth consistent, use a depth stop. This is like a guide that helps you know how deep to drill each time.

- Check your tailstock alignment regularly.

- Use a depth stop for better depth control.

- Practice makes perfect—drill multiple times.

How can tailstock adjustments improve drilling accuracy?

Tailstock adjustments enhance drilling by keeping the bit aligned and steady. This leads to cleaner holes and better results.

Maintenance Tips for Tailstock Components

Regular maintenance practices to prolong the lifespan of the tailstock. Signs of wear and tear to watch for in tailstock components.Taking care of the tailstock is important for using it a long time. Regular checks help spot issues early. Here are simple ways to keep it in good shape:

- Clean the tailstock regularly to remove dirt.

- Lubricate the moving parts to avoid rust.

- Check for loose screws or parts that might wobble.

Watch for signs that show wear, like:

- Unusual noises while working.

- Difficulty in moving the tailstock.

- Visible damage or rust on parts.

By following these tips, your tailstock will work better and last longer!

What are the signs of wear in tailstock components?

Signs of wear include strange sounds, difficulty moving parts, and visible damage. Checking often helps you catch problems early.

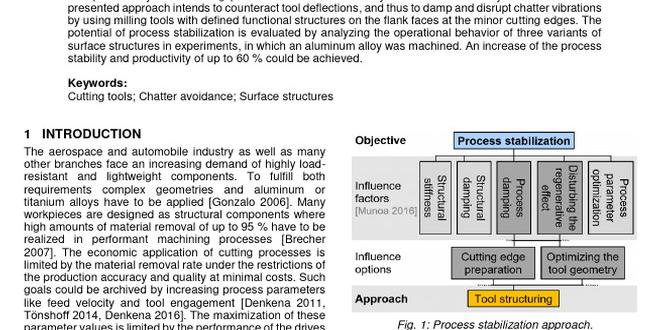

Advanced Techniques for Professionals

Incorporating taper drilling for specialized applications. Using custom jigs and fixtures to improve accuracy and efficiency.Having some fun while mastering new skills? Yes, please! Try taper drilling to add a twist—literally! This technique helps create angled holes for specialized jobs. Think of it as giving your drill a stylist makeover! Next up, custom jigs and fixtures can be your best friends. They make your work much more accurate and efficient. It’s like using a map instead of wandering around aimlessly! Why struggle straightening your screws when you can dance right through?

| Technique | Benefit |

|---|---|

| Taper Drilling | Allows for angled holes. |

| Custom Jigs | Improves accuracy and efficiency. |

Safety Considerations in Tailstock Drilling

Essential safety gear and practices while operating the lathe. How to handle emergencies and minimize risks during drilling operations.Safety is key when using a lathe! Always wear your safety goggles to protect your eyes. Ear protection is important too; lathes can be loud. Keep your hair tied back and avoid loose clothing that can get caught. Know how to stop the machine quickly in case of an emergency. Practice safe positioning while working, just like you would in dodgeball! And remember, the best tool for keeping yourself safe is your brain—think before you drill, and you’ll avoid reaching for that first aid kit.

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris |

| Ear Protection | Reduces noise exposure |

| Hair Tie | Keeps hair away from machinery |

| Fitted Clothing | Prevents snags or accidents |

Following these tips will help you stay safe and avoid accidents. After all, a safe workshop is a happy workshop!

Conclusion

In summary, using a lathe tailstock for center drilling is crucial for accuracy. Always keep your drill bit sharp and aligned. Remember to use the right speed and pressure for best results. We encourage you to practice these tips and explore more about lathe techniques. With time, you’ll master this skill and improve your projects!FAQs

What Are The Best Practices For Aligning The Tailstock With The Lathe Bed Before Center Drilling?To align the tailstock with the lathe bed, start by loosening the tailstock clamping screw. Slide the tailstock up against the lathe bed. Use a straight piece, like a ruler, to check if it’s straight. Adjust until it lines up perfectly. Finally, tighten the clamping screw to hold it in place.

How Do You Choose The Correct Size Of Drill Bit Or Center Drill For Your Specific Project?To choose the right size of a drill bit or center drill, start by checking the size of the hole you need. You can measure the depth and width of the hole or look at your project instructions. It’s also good to think about what material you are drilling into, like wood or metal. When in doubt, pick a bit that is slightly smaller; you can always make the hole bigger if needed.

What Techniques Can Be Used To Minimize Deflection During Tailstock Center Drilling?To reduce deflection when drilling with a tailstock, you can use a few simple methods. First, make sure the drill bit is sharp. A sharp bit cuts better and helps prevent bending. Second, use the correct speed for the drill. Too fast can cause extra pressure that leads to deflection. Finally, keep the tailstock locked tightly in place while drilling to hold everything steady.

How Can You Troubleshoot Issues Like Runout Or Vibration When Using The Tailstock For Center Drilling?To fix runout or vibration when using the tailstock for center drilling, first check if the tailstock is tight. We can also make sure the drill bit is sharp and straight. If things still vibrate, try adjusting the speed of the machine. Lastly, look at the workpiece and make sure it’s balanced and secure.

What Safety Precautions Should Be Taken When Operating The Tailstock And Performing Center Drilling?When using the tailstock, make sure your hands are clear of moving parts. Always wear safety goggles to protect your eyes. Check that the drill bit is tight and secure before starting. Keep your workspace clean to avoid accidents. Lastly, never rush—take your time to stay safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Aligning The Tailstock With The Lathe Bed Before Center Drilling? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock with the lathe bed, start by loosening the tailstock clamping screw. Slide the tailstock up against the lathe bed. Use a straight piece, like a ruler, to check if it’s straight. Adjust until it lines up perfectly. Finally, tighten the clamping screw to hold it in place.”}},{“@type”: “Question”,”name”: “How Do You Choose The Correct Size Of Drill Bit Or Center Drill For Your Specific Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right size of a drill bit or center drill, start by checking the size of the hole you need. You can measure the depth and width of the hole or look at your project instructions. It’s also good to think about what material you are drilling into, like wood or metal. When in doubt, pick a bit that is slightly smaller; you can always make the hole bigger if needed.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Minimize Deflection During Tailstock Center Drilling? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce deflection when drilling with a tailstock, you can use a few simple methods. First, make sure the drill bit is sharp. A sharp bit cuts better and helps prevent bending. Second, use the correct speed for the drill. Too fast can cause extra pressure that leads to deflection. Finally, keep the tailstock locked tightly in place while drilling to hold everything steady.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Issues Like Runout Or Vibration When Using The Tailstock For Center Drilling? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix runout or vibration when using the tailstock for center drilling, first check if the tailstock is tight. We can also make sure the drill bit is sharp and straight. If things still vibrate, try adjusting the speed of the machine. Lastly, look at the workpiece and make sure it’s balanced and secure.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating The Tailstock And Performing Center Drilling? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the tailstock, make sure your hands are clear of moving parts. Always wear safety goggles to protect your eyes. Check that the drill bit is tight and secure before starting. Keep your workspace clean to avoid accidents. Lastly, never rush—take your time to stay safe.”}}]}