Have you ever faced problems with the tailstock quill on your lathe? It’s more common than you think! Many woodworkers and metalworkers experience trouble when trying to retract the tailstock quill. This can frustrate anyone in the workshop.

Imagine you’re working on a beautiful piece of wood. You’re in the groove, and suddenly, the tailstock quill doesn’t budge. What now? This issue can slow down your project and leave you feeling stuck.

It’s surprising to know that even skilled machinists can struggle with this quill retraction problem. Understanding why this happens can save you time and effort. In this article, we dive into the lathe tailstock quill retraction issue, exploring its causes and solutions. Let’s sharpen our tools and get to the bottom of this!

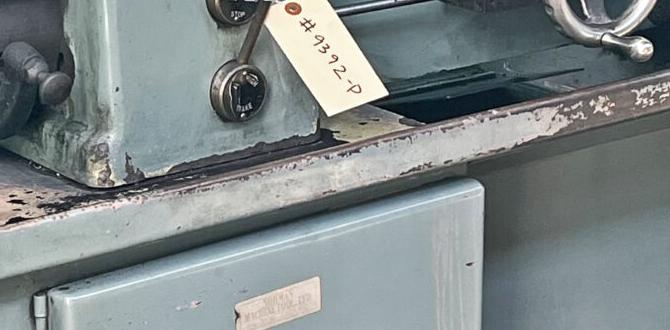

Lathe Tailstock Quill Retraction Issue: Troubleshooting Tips

Lathe Tailstock Quill Retraction Issue

The lathe tailstock quill retraction issue can be frustrating for users. Many face problems when the quill doesn’t retract smoothly. This can hinder your work and cause delays. Have you ever had to stop mid-project to fix it? Regular maintenance is key. Checking lubrication and ensuring no obstructions exist can help. Did you know that even small debris can lead to these problems? Staying aware helps ensure your lathe runs smoothly and efficiently.What is a Lathe Tailstock Quill?

Definition and function of the tailstock quill. Importance of the quill in lathe operations.A lathe tailstock quill is a crucial part of a lathe machine. It helps support and adjust workpieces while they spin. Imagine it as a trusty friend holding your pizza while you slice it; without it, things would get messy! The quill’s main job is to provide precise depth control, making your cuts neat and accurate.

Without the quill, the lathe would struggle to make smooth finishes. It’s like trying to ride a bicycle without wheels; it just doesn’t work! So, knowing how to use and fix the tailstock quill can save you from many headaches in the workshop.

| Function | Importance |

|---|---|

| Controls depth | Ensures accuracy |

| Supports workpieces | Makes smooth finishes |

Common Causes of Quill Retraction Issues

Mechanical wear and tear. Improper adjustment settings.Several issues can cause problems with the quill retraction. First, mechanical wear and tear can happen over time. Moving parts can become weak or damaged. This makes it hard for the quill to retract properly. Second, improper adjustment settings can also lead to issues. If the settings are not right, the quill cannot move freely. Here are two key reasons:

- Mechanical Wear and Tear: Parts may weaken with use.

- Improper Adjustment Settings: Wrong settings block smooth movement.

Keeping your lathe in good shape helps avoid these issues. Regular checks help spot problems early.

What are common problems affecting the quill retraction?

Common problems include wear and tear on parts and incorrect adjustments. Keeping an eye on your machine’s parts can help you catch these issues fast.

Symptoms of Retraction Problems

Difficulty in retracting the quill. Inconsistent or jerky movement.Having trouble with the tailstock quill? Here are some signs to watch for. You might feel difficulties when trying to pull the quill back. Instead of moving smoothly, it may jerk or stop unexpectedly. This can make tasks much harder. Look out for these symptoms:

- Difficulty pulling the quill back

- Inconsistent movement that feels shaky

- Frequent stopping during retraction

Recognizing these signs can help you fix the issue faster.

What causes quill retraction issues?

Common causes include dirt buildup, lack of lubrication, or worn parts. Regular maintenance can prevent these problems.

How to Diagnose Quill Retraction Issues

Visual inspections for wear and damage. Testing quill movement and adjustments.Start by checking the tailstock quill for any visible wear or damage. Look for dents, rust, or cracks. Measure the quill’s movement. Can it slide smoothly? If it sticks, it may need some adjustments.

Next, test the quill action. Move it in and out gently. Does it retract easily? If not, it might need a little tightening. Regular upkeep helps keep things running well.

- Inspect for cracks or rust

- Check movement and smoothness

- Adjust if it doesn’t retract properly

What are the signs of quill retraction problems?

Look for sticking or sluggish movement. If the quill doesn’t move at all or makes strange noises, it indicates a problem. Also, keep an eye on any strange alignment issues. These signs help you catch problems early.

Step-by-Step Solutions for Retraction Issues

Adjusting the tailstock quill alignment. Lubrication and maintenance tips.Having trouble with your lathe tailstock quill? Don’t fret! Adjusting the tailstock quill alignment is simple. First, check if it’s straight. Use a level to see if it’s leaning like a sleepy cat. If it is, adjust the screws until it stands tall and proud.

Regular lubrication keeps things running smoothly. Apply a bit of oil exactly where it’s needed. Think of it as giving your lathe a nice spa day! Without maintenance, it might squeak louder than a rubber duck. Stay on top of it, and enjoy years of happy turning!

| Task | Frequency |

|---|---|

| Check Alignment | Every Month |

| Lubricate Parts | Weekly |

Preventive Measures to Avoid Future Issues

Regular maintenance routines. Proper usage practices.To keep your lathe running smoothly, regular maintenance is key. Check the tailstock quill often to spot any issues early. Clean it up and apply some oil like a tasty condiment on a hot dog! Proper usage also matters. Don’t put too much pressure or use it in odd ways. Follow these tips:

| Routine | Frequency |

|---|---|

| Check Quill Alignment | Weekly |

| Clean and Lubricate | Monthly |

| Test Retract Mechanism | Before Use |

By following these steps, you’ll avoid future headaches! Remember: a happy lathe makes for a happy you!

When to Seek Professional Help

Signs that indicate the need for expert repair. Benefits of professional maintenance services.Sometimes, machines need help. If your lathe tailstock quill doesn’t move smoothly or makes strange noises, it’s time to call a pro. Here are signs you should look for:

- Quill gets stuck.

- Unusual sounds during operation.

- Difficulty in adjusting the quill.

Seeking professional help has great benefits:

- Experts quickly find the problem.

- They ensure your machine runs safely.

- Regular maintenance extends machine life.

In the long run, expert care keeps your equipment in top shape.

How do I know if I need to get professional service?

If you see any of the signs mentioned, it’s best to **contact a professional**. Their experience can save you time and money.

Conclusion

In summary, the lathe tailstock quill retraction issue can slow your work and cause frustration. You should regularly check for dirt or damage. Keeping moving parts clean helps everything run smoothly. If you keep these tips in mind, you can solve problems easily. For more details, consider reading guides on lathe maintenance or watch tutorial videos for better understanding.FAQs

What Are The Common Causes Of A Lathe Tailstock Quill Not Retracting Properly During Operation?A lathe tailstock quill might not retract properly for a few reasons. First, it could be stuck because of dirt or rust. Second, the screw that helps it move might be loose or broken. Lastly, if you overload it or push too hard, it can get jammed. Always check these parts to make sure everything works well!

How Can I Troubleshoot A Lathe Tailstock Quill That Seems To Be Stuck Or Difficult To Retract?First, check if there’s dirt or debris around the tailstock quill. You can clean it with a soft cloth. Next, make sure the quill is not too tight. You can loosen any screws or knobs gently. If it still doesn’t move, try adding a little oil to help it slide better. If it still won’t budge, ask someone for help.

What Maintenance Practices Can Help Prevent Tailstock Quill Retraction Issues On A Lathe?To prevent tailstock quill retraction issues on a lathe, you should clean it regularly. Dust and chips can get stuck and cause problems. You also need to lubricate moving parts with oil. This keeps everything working smoothly. Lastly, check for any loose parts and tighten them to make sure everything is secure.

Are There Any Specific Tools Or Lubricants Recommended For Addressing Tailstock Quill Retraction Problems?Yes, you can use some tools and lubricants to fix tailstock quill problems. A good choice is a light machine oil. It helps the quill move easily. You might also need some tools like a wrench to tighten loose parts. Make sure you clean the area before applying the oil.

How Does The Alignment Of The Tailstock Affect The Retraction Of The Quill, And What Adjustments Can Be Made To Resolve Issues?When the tailstock is not aligned correctly, the quill may not pull back smoothly. This can make it hard for you to use it. To fix this, you can adjust the tailstock until it lines up right. Check if the tailstock is tight and straight. This will help the quill retract easier.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Causes Of A Lathe Tailstock Quill Not Retracting Properly During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe tailstock quill might not retract properly for a few reasons. First, it could be stuck because of dirt or rust. Second, the screw that helps it move might be loose or broken. Lastly, if you overload it or push too hard, it can get jammed. Always check these parts to make sure everything works well!”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot A Lathe Tailstock Quill That Seems To Be Stuck Or Difficult To Retract? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, check if there’s dirt or debris around the tailstock quill. You can clean it with a soft cloth. Next, make sure the quill is not too tight. You can loosen any screws or knobs gently. If it still doesn’t move, try adding a little oil to help it slide better. If it still won’t budge, ask someone for help.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Prevent Tailstock Quill Retraction Issues On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent tailstock quill retraction issues on a lathe, you should clean it regularly. Dust and chips can get stuck and cause problems. You also need to lubricate moving parts with oil. This keeps everything working smoothly. Lastly, check for any loose parts and tighten them to make sure everything is secure.”}},{“@type”: “Question”,”name”: “Are There Any Specific Tools Or Lubricants Recommended For Addressing Tailstock Quill Retraction Problems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use some tools and lubricants to fix tailstock quill problems. A good choice is a light machine oil. It helps the quill move easily. You might also need some tools like a wrench to tighten loose parts. Make sure you clean the area before applying the oil.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of The Tailstock Affect The Retraction Of The Quill, And What Adjustments Can Be Made To Resolve Issues? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is not aligned correctly, the quill may not pull back smoothly. This can make it hard for you to use it. To fix this, you can adjust the tailstock until it lines up right. Check if the tailstock is tight and straight. This will help the quill retract easier.”}}]}