Have you ever wondered how to get the perfect threads on a lathe? Selecting the right lathe thread dial gear can make all the difference. Without it, your threads might not fit together right. This could mean the difference between a smooth operation and a frustrating project.

Imagine trying to screw two pieces together, but they just won’t align. Frustrating, isn’t it? Well, the key often lies in the gear selection. The right gear helps create perfect threads every time. Did you know that even a small difference in gear can lead to big changes in quality?

In this article, we will explore how to choose the best lathe thread dial gear. You will learn tips and tricks that can improve your projects. Whether you are a beginner or a seasoned pro, understanding gear selection is important. Let’s dive in and make your lathe work better!

Lathe Thread Dial Gear Selection: A Comprehensive Guide

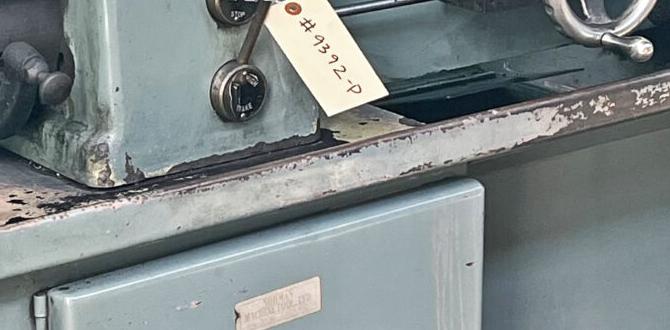

Lathe Thread Dial Gear Selection

Choosing the right lathe thread dial gear is crucial for precision in threading. This selection affects how smoothly the thread engages with the material. Key factors include gear size, type, and compatibility with your lathe model. Did you know that a mismatched gear can lead to imprecise cuts? Finding the perfect gear enhances your work quality and saves time. Make informed choices and enjoy smoother, more accurate projects with the right gear!Understanding Lathe Thread Dial Gears

Definition and purpose of thread dial gears in lathes. Importance of precision in gear selection for threading applications.Thread dial gears help lathes shape metal and wood by making precise threads. They ensure that every turn is equal and accurate. This accuracy is important for strong and safe parts. Poor gear choice can lead to mistakes, making parts weak or unusable. Choosing the right gear is key to good results.

What are the benefits of using thread dial gears?

Thread dial gears help machines create better threads, making work easier and faster. They also save time and make tasks more efficient. People can complete projects with fewer errors when they use the right gear.

- Improved accuracy

- Faster production

- Less waste

Factors to Consider When Selecting a Thread Dial Gear

Gear size and compatibility with your lathe model. Material quality and durability for longterm use.Choosing the right thread dial gear can feel like shopping for shoes—size matters! First, check the gear size to ensure it fits your lathe model. A mismatch can turn your project into a wobbly disaster. Next, think about material quality. You want something tough; after all, you’re not just repairing your toy! Gear up with durable materials for a long life. Remember, a good selection keeps your lathe spinning smoothly and your projects on track.

| Factor | Importance |

|---|---|

| Gear Size | Must match the lathe model |

| Material Quality | Ensures long-term durability |

The Role of Gear Ratios in Threading Accuracy

Explanation of gear ratios and their impact on threading. How to calculate and choose the right gear ratios for your projects.Gear ratios are like the magic recipe for getting threading just right. They decide how fast your lathe turns the tool compared to the workpiece. A higher gear ratio means slower tool speed, leading to detailed threads. To find the best gear ratio, you can use this simple formula: Divide the number of teeth on the driven gear by the number of teeth on the driving gear. Want to know how that looks in numbers?

| Driven Gear Teeth | Driving Gear Teeth | Gear Ratio |

|---|---|---|

| 20 | 10 | 2:1 |

| 30 | 15 | 2:1 |

| 10 | 5 | 2:1 |

This means if the driven gear has 20 teeth and the driving gear has 10, you have a 2:1 ratio. So, pick wisely if you want your threads to be the envy of the machine shop!

Installation and Adjustment Tips for Thread Dial Gears

Stepbystep guide on installing thread dial gears. Common adjustments for optimal performance and accuracy.Installing thread dial gears can be a fun puzzle. First, line up the gear with the spindle. Tighten it carefully, but not too tight—no one likes a cranky gear! Check the alignment using a straight edge for a smooth fit. Next, adjust the tension. If it’s too loose, your threads could be wonky. And remember, practice makes perfect! Adjust as needed to keep everything precise. Here’s a quick table for a simple guide:

| Step | Action |

|---|---|

| 1 | Align the gear with the spindle |

| 2 | Tighten gently |

| 3 | Check alignment with a straight edge |

| 4 | Adjust tension for smooth operation |

Now you’re ready to make some awesome threads! Keep tinkering until everything flows smoothly, and your lathe will thank you.

Maintenance Best Practices for Longevity

Regular maintenance tips to keep your thread dial gear in top shape. Signs that indicate the need for gear replacement.Keeping your thread dial gear in top shape is important for smooth operation. Regular maintenance helps it last longer. Here are some tips to consider:

- Clean the gear regularly to remove dust and dirt.

- Check for any signs of wear or damage.

- Lubricate moving parts to prevent rust.

- Inspect the gears for proper alignment.

Watch for signs that mean it’s time to replace your gear. If you notice strange noises or difficulty in movement, it could be a warning. Early attention can prevent bigger problems later.

What are the signs of gear replacement?

Signs include loud noises, grinding sounds, or visible wear. Ignoring these signs can lead to more issues.

Common Mistakes to Avoid in Gear Selection

Typical errors made by beginners in selecting thread dial gears. How to troubleshoot and rectify selection mistakes.Beginners often make mistakes in selecting thread dial gears. One common error is choosing the wrong size. This can lead to poor alignment and bad cuts. Another mistake is not checking compatibility with the lathe. To fix these issues, always double-check measurements. Replace any incompatible gears and test the setup before starting work. Avoid assuming a gear fits simply because it looks good. With care and attention, you can achieve better results in your projects.

What should you check when choosing a dial gear?

Check the gear size, pitch, and compatibility with your lathe. Use clear measurements to ensure a proper fit. Reading the specifications carefully helps you avoid mistakes.

- Verify the size of the gear.

- Make sure the pitch matches your projects.

- Ensure the gear is compatible with your lathe model.

Conclusion

In summary, choosing the right lathe thread dial gear is crucial for precise threading. Understanding gear sizes and compatibility helps you make better choices. Check your lathe’s manual for specific recommendations. We encourage you to explore more resources online or speak to experienced machinists for tips. Practicing with the right gear will improve your threading skills significantly!FAQs

Certainly! Here Are Five Questions Related To Lathe Thread Dial Gear Selection:Sure! Here are five questions about choosing gears for a lathe’s thread dial: 1. Why do we need different gears for threading? 2. How do you pick the right gear size? 3. What happens if we use the wrong gear? 4. Can gears be switched easily while working? 5. How do we know which gear works best? Let me know if you’d like answers to any of these!

Of course! Please provide me with the question you’d like me to answer.

What Are The Key Factors To Consider When Selecting The Appropriate Thread Dial Gear For A Specific Lathe Model?When choosing a thread dial gear for your lathe, you need to think about a few important things. First, check the size of the gear. It should fit your lathe properly. Next, look at the thread pitch. This tells you how fine or thick the threads are. Lastly, make sure the gear is made for your specific lathe model. If you think about these factors, you’ll find the right gear easily!

How Does The Gear Ratio Of The Dial Gear Affect The Accuracy And Quality Of Threads Produced On A Lathe?The gear ratio of the dial gear helps control the movement of the lathe. When it’s adjusted right, the threads made will be very even and smooth. If the gear ratio is wrong, the threads might be wobbly or too loose. So, a good gear ratio makes better threads! It’s like having the right settings on a video game to win.

What Are The Common Sizes And Types Of Thread Dial Gears Available, And How Do They Correspond To Different Threading Applications?Thread dial gears come in different sizes, like small, medium, and large. Each size helps you make different types of threads on metal or wood. For example, a small gear is great for tiny threads, while a large gear works for big threads. You use the right gear based on what you are making, so everything fits together well!

How Do You Troubleshoot Issues Related To Thread Dial Gear Misalignment Or Wear, And What Steps Can Be Taken To Resolve Them?To fix problems with the thread dial gear, first, check if it is properly aligned. You can do this by looking closely at how it sits with other parts. If it looks crooked, gently adjust it until it lines up right. Next, check for any damage or wear on the gear. If it’s worn out, we might need to replace it with a new one. Always make sure to keep everything clean and oiled to help it work better!

Can You Explain The Process Of Calibrating The Thread Dial Gear To Ensure Consistent Thread Pitch When Using A Lathe?To calibrate the thread dial gear on a lathe, start with the machine off. Turn the handwheel until the thread dial shows a number, usually zero. Next, move the carriage until the tool matches where the thread starts. You want the markings on the dial to line up perfectly. After that, you can make a test cut to see if the threads are even. Adjust if needed and repeat until they match nicely!