Have you ever watched a lathe in action? It’s like magic! A simple piece of metal transforms into something useful right before your eyes. But have you considered the tools that make this happen? One essential tool for a metal lathe is the quick change tool post, especially when it comes to threading.

Lathe threading is an art. It allows you to create precise threads for screws and bolts. But how do you make this process faster and easier? That’s where the quick change tool post shines! It lets you switch tools in seconds. You can go from threading to cutting without missing a beat.

Imagine you’re working on a project. You need to switch from making a groove to cutting a thread. With a quick change tool post, you can do this almost instantly! This tool can save you time and help you finish your work with ease.

Did you know that the design of the quick change tool post has been around for a long time? It has been helping machinists for years. In this article, we’ll explore how to use it effectively for lathe threading and other tasks. So let’s dive in!

Lathe Threading: Metal Lathe Quick Change Tool Post Guide

Lathe Threading Metal Lathe Quick Change Tool Post

Using a metal lathe for threading can be exciting! The quick change tool post is a handy feature that helps make tasks easier. Did you know it allows rapid swapping of tools? This means less downtime and more cutting! With the right setup, users can create precise threads for various projects. Understanding this tool can lead to impressive results, such as custom fittings and parts. Exploring lathe threading not only boosts skills but can be a fun way to create!Understanding Lathe Threading Basics

Definition of lathe threading. Importance of precision in threading operations.Lathe threading is a way of making grooves or threads on metal. Think of it like putting on the most fashionable twist to your favorite snack—super cool, right? Precision is key here. One tiny mistake can lead to a total mess! Imagine trying to screw a lid that just won’t fit. Yikes! Using a lathe means you get to create perfect threads every time, which is important for strong connections.

| Threading Basics | Importance |

|---|---|

| Definition: Creating threads on metal. | Precision: Ensures the right fit! |

| Use: For screws, bolts, and more. | Quality: Leads to better products. |

Components of a Metal Lathe

Key parts of a metal lathe. How each component influences threading quality.A metal lathe has many important parts. Each part helps make the threading process better. Some of the key components include:

- Bed: The heavy base supports all parts. It keeps everything stable.

- Headstock: This part holds the spindle. It drives the rotation of the metal.

- Tailstock: This supports the other end of the metal. It ensures smooth movement.

- Tool Post: This holds the cutting tool. It can be quickly changed for different tasks.

Each component plays a role in quality threading. A sturdy bed prevents vibrations. A strong tool post allows precise cuts. In short, every piece is vital for great results.

Why is the tool post important?

The tool post is crucial for accurate cuts. It holds the tool firmly in place. A quick change tool post makes switching tools fast and easy. This saves time and keeps the project moving smoothly. Proper tool support helps ensure high-quality threading.

Selecting the Right Tooling for Threading

Types of threading tools compatible with quick change tool posts. Factors to consider when choosing tools for specific projects.Choosing the right tools for threading can feel as tricky as trying to find a needle in a haystack. You need to consider what type of threading tool will fit your quick change tool post. Common options include dies, taps, and threading inserts. Each type serves different purposes, so pick wisely! Factors like the material of your project and the threads’ size matter, too. Remember, the right tool can save you time and make your project smoother. A happy lathe is a productive lathe!

| Tool Type | Best For |

|---|---|

| Dies | External threads |

| Taps | Internal threads |

| Threading Inserts | Various materials |

Setting Up Your Lathe for Threading

Stepbystep guide to setting up a metal lathe for threading. Importance of tool alignment and settings.Setting up your lathe for threading is easy. First, make sure the machine is clean. Next, align your tool. This step is crucial for good threads. Check the speed and feed rate. Adjust the settings based on the material you’re using. Lastly, run a test cut. This helps ensure everything works well before you begin. Follow these steps for safer and better results.

- Clean the lathe

- Align the cutting tool

- Check speed and feed rate

- Run a test cut

Why is tool alignment important?

Tool alignment is key to getting accurate threads. Misalignment can cause uneven cuts, which could ruin your work. Proper setup saves time and materials.

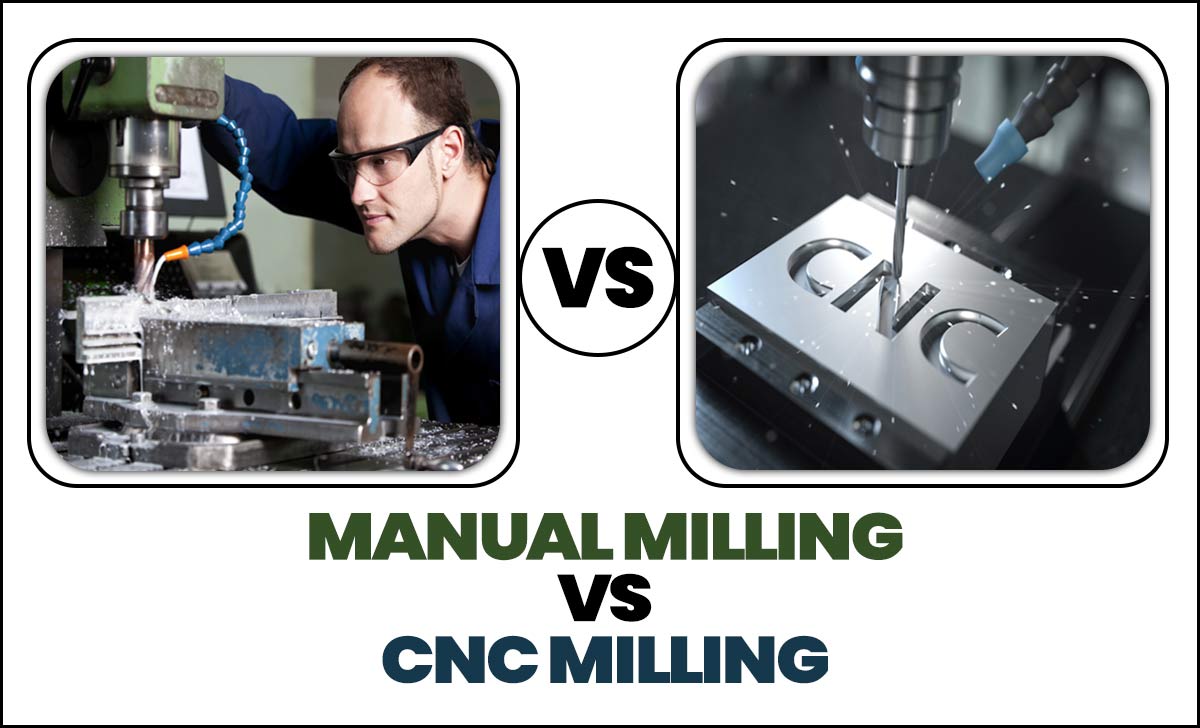

Threading Techniques and Methods

Different threading techniques using a metal lathe. Pros and cons of each threading method.Threading on a metal lathe can be a game-changer for your projects! You have several techniques to choose from, each with their own quirks. For example, the single-point threading method offers high precision, but it can be time-consuming. Meanwhile, roll threading is faster and creates strong threads, but it requires specialized tools. Don’t forget tapping, which is quick and works well in softer metals, but can sometimes break. Check out this handy table for a quick comparison!

| Technique | Pros | Cons |

|---|---|---|

| Single-Point Threading | High precision | Time-consuming |

| Roll Threading | Fast and strong | Needs special tools |

| Tapping | Quick and easy | Can break |

In the end, choose the method that fits your project best. Happy threading!

Common Troubleshooting Tips for Lathe Threading

Identifying common issues in threading. Effective solutions to improve threading outcomes.Threading on a lathe can be tricky. Many problems can arise during this process. Common issues include improper tool angles and incorrect speeds. Poor alignment can also cause mistakes. Fixing these problems can make your threading better. Here are some tips:

- Check the tool angle.

- Adjust the speed.

- Ensure proper tool alignment.

- Use sharp tools for cleaner threads.

With these solutions, you can improve your threading outcomes and get great results every time.

What are some common lathe threading problems?

The most common lathe threading problems include:

- Incorrect tool setup

- Inconsistent feed rates

- Worn out cutting tools

Fixing these issues will lead to smoother results.

Maintenance of Quick Change Tool Posts

Regular maintenance practices for longevity. Troubleshooting potential issues with tool posts.Quick change tool posts need regular care. This helps them last longer and work better. Check for dirt and oil buildup. Clean them often to avoid jams. Listen for strange noises, which could mean trouble. If the tool wobbles, tighten it right away. Here are some easy maintenance tips:

- Clean regularly.

- Check for loose parts.

- Lubricate moving parts.

- Replace worn tools.

By staying ahead, you can avoid major issues and keep your tool post in top shape.

What are common issues with quick change tool posts?

Common issues include wobbling tools, jamming, and excessive noise. Proper maintenance can help prevent these problems.Safety Practices When Threading on a Lathe

Essential safety protocols for lathe operations. Importance of personal protective equipment (PPE).Using a lathe can be fun, but safety is no laughing matter! Always remember to wear your personal protective equipment (PPE). This includes safety goggles, gloves, and ear protection. Don’t be the person who gets a haircut from a wayward metal chip!

Start with a clean workspace. Check for loose clothing and keep long hair tied back. Clear any clutter, so you can focus on your masterpiece. Remember, a bit of safety goes a long way in avoiding a bad hair day or worse!

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect eyes from flying debris |

| Gloves | Keep your hands safe and clean |

| Ear Protection | Silence the noise of spinning metal |

Real-World Applications of Lathe Threading

Industries that benefit from precision lathe threading. Examples of projects where threading is essential.Many industries use lathe threading to make important parts. These include manufacturing, automotive, and aerospace. In these fields, precise threading is crucial for assembling and connecting components. For example:

- Automobile engines need threaded bolts to hold them together.

- Aerospace parts require strong, precision threads to ensure safety.

- Manufacturing equipment often uses threaded parts for assembly.

In these projects, good threading means a better outcome. Without lathe threading, many essential tasks would be impossible.

What are common applications of lathe threading?

Common applications include creating precision screws, automotive components, and custom fittings for machinery.Conclusion

In summary, a lathe threading metal lathe with a quick change tool post makes metalworking easier and faster. You can quickly switch tools, improving your projects’ efficiency. Explore various tools and techniques to enhance your skills. Remember, practice is key! Keep learning, and don’t hesitate to dive into more resources or tutorials to master your lathe threading.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Threading, Metal Lathe, And Quick Change Tool Posts:Sure! Here are five important points about lathe threading, metal lathes, and quick change tool posts. 1. A lathe is a machine that helps shape metal pieces. 2. Threading on a lathe creates a spiral groove on metal, like a screw’s shape. 3. Quick change tool posts let you swap tools fast on a lathe. 4. This saves time when you’re working and helps you make different shapes. 5. Using a metal lathe helps you build cool projects and tools easily.

Sure! Please provide me with the question you would like me to answer.

What Are The Advantages Of Using A Quick Change Tool Post On A Metal Lathe For Threading Operations?Using a quick change tool post on a metal lathe makes threading easier and faster. You can switch tools without special tools or much fuss. This saves time when you need to change cuts. It also helps you make more accurate threads, so your work looks better. Overall, it makes metalworking simpler and more fun!

How Do You Properly Set Up A Quick Change Tool Post For Threading On A Metal Lathe?To set up a quick change tool post for threading on a metal lathe, first turn off the machine. Next, make sure the tool post is clean and free of dust. Then, choose the right threading tool and place it in the tool post. Tighten the screws to hold the tool in place. Finally, position the tool so it’s just above the workpiece and adjust it as needed.

What Types Of Threading Tools Are Compatible With Quick Change Tool Posts For Metal Lathes?Quick change tool posts work with several threading tools for metal lathes. These include tap holders, threading bits, and dies. You can easily swap them out for different jobs. They help you make screws and holes quickly. Using these tools makes your work faster and easier!

How Does The Threading Process Differ When Using A Quick Change Tool Post Compared To A Standard Tool Holder?When using a quick change tool post, you can switch tools faster. This makes threading easier and quicker. With a standard tool holder, you need to stop and change the tool more slowly. It can take more time to set things up. So, the quick change tool post helps you work faster.

What Maintenance Tips Should Be Followed To Ensure The Longevity And Accuracy Of A Quick Change Tool Post On A Metal Lathe?To keep your quick change tool post in good shape, clean it regularly. Use a soft cloth to wipe away dust and chips. Check the screws and nuts to make sure they are tight, but not too tight. Apply a little machine oil to keep it running smoothly. Lastly, store it safely when you are not using your lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Threading, Metal Lathe, And Quick Change Tool Posts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five important points about lathe threading, metal lathes, and quick change tool posts. 1. A lathe is a machine that helps shape metal pieces. 2. Threading on a lathe creates a spiral groove on metal, like a screw’s shape. 3. Quick change tool posts let you swap tools fast on a lathe. 4. This saves time when you’re working and helps you make different shapes. 5. Using a metal lathe helps you build cool projects and tools easily.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Quick Change Tool Post On A Metal Lathe For Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a quick change tool post on a metal lathe makes threading easier and faster. You can switch tools without special tools or much fuss. This saves time when you need to change cuts. It also helps you make more accurate threads, so your work looks better. Overall, it makes metalworking simpler and more fun!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Quick Change Tool Post For Threading On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a quick change tool post for threading on a metal lathe, first turn off the machine. Next, make sure the tool post is clean and free of dust. Then, choose the right threading tool and place it in the tool post. Tighten the screws to hold the tool in place. Finally, position the tool so it’s just above the workpiece and adjust it as needed.”}},{“@type”: “Question”,”name”: “What Types Of Threading Tools Are Compatible With Quick Change Tool Posts For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Quick change tool posts work with several threading tools for metal lathes. These include tap holders, threading bits, and dies. You can easily swap them out for different jobs. They help you make screws and holes quickly. Using these tools makes your work faster and easier!”}},{“@type”: “Question”,”name”: “How Does The Threading Process Differ When Using A Quick Change Tool Post Compared To A Standard Tool Holder?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a quick change tool post, you can switch tools faster. This makes threading easier and quicker. With a standard tool holder, you need to stop and change the tool more slowly. It can take more time to set things up. So, the quick change tool post helps you work faster.”}},{“@type”: “Question”,”name”: “What Maintenance Tips Should Be Followed To Ensure The Longevity And Accuracy Of A Quick Change Tool Post On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your quick change tool post in good shape, clean it regularly. Use a soft cloth to wipe away dust and chips. Check the screws and nuts to make sure they are tight, but not too tight. Apply a little machine oil to keep it running smoothly. Lastly, store it safely when you are not using your lathe.”}}]}