Have you ever seen a metal lathe in action? These machines are amazing! They help shape metal into various parts. One of the coolest features of a metal lathe is the threading dial. But what does it really do?

The threading dial is essential for cutting threads on a workpiece. Picture this: you want to make a screw or a nut. You need perfect threads for them to fit. The threading dial guides you to make those threads just right!

Did you know that using the threading dial can make your work easier? It helps you keep track of your cuts. This way, your metal pieces turn out looking great. You won’t believe how much easier it is to create precise threads!

In this article, we will explore how to use the lathe threading dial. We will also share tips to help you get the best results. Ready to dive into the world of metal lathe threading?

Mastering Lathe Threading: The Essential Metal Lathe Threading Dial Guide

Understanding Lathe Threading with a Metal Lathe Threading Dial

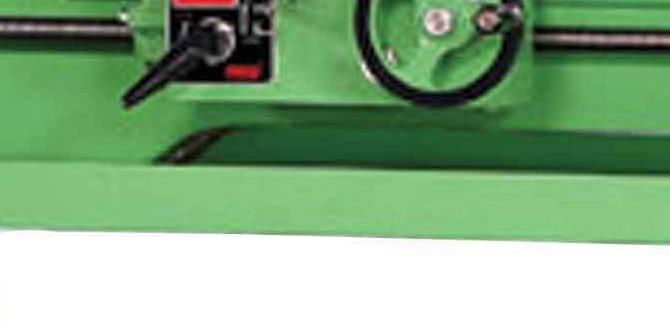

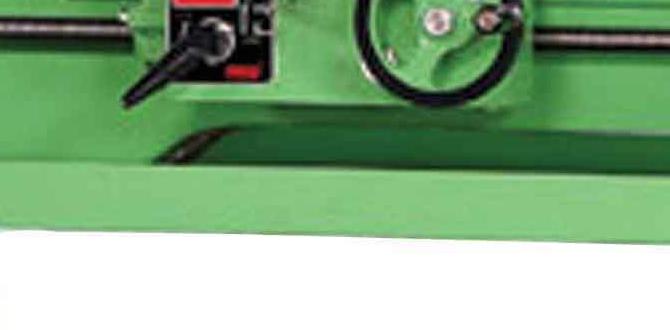

Lathe threading is an important skill in metalworking. A metal lathe threading dial helps you create precise threads on metal pieces. Have you ever wondered how craftsmen make those perfect screws or bolts? The threading dial marks the position for cuts, ensuring accuracy. It allows you to repeat the same measurement easily. Learning to use this tool opens up possibilities for making custom parts. Whether for hobby projects or professional tasks, mastering lathe threading can enhance your skills.Components of a Metal Lathe

Description of the key parts of a metal lathe relevant to threading.. Role of the threading dial in the threading process..A metal lathe has several important parts that help it work well. Key components include the headstock, spindle, tailstock, and carriage. Each part plays a role in shaping metal. The threading dial is especially important for threading. It helps the user line up the cutter with the workpiece for precise threads.

Using the threading dial properly creates clean, accurate threads. This makes the process smoother and faster.

What is the threading dial used for?

The threading dial helps you create exact threads by guiding your cuts. It’s like a map that shows where to go next!

Key components of a metal lathe:

- Headstock: Holds the spindle and motor.

- Spindle: Rotates the workpiece.

- Tailstock: Supports the other end of the workpiece.

- Carriage: Moves the cutting tool.

- Threading dial: Helps with precise threading.

Setting Up the Lathe for Threading

Stepbystep guide to preparing a metal lathe for threading operations.. Importance of tool selection and setup adjustments..To prepare your metal lathe for threading, start by gathering the right tools. Selecting quality tools is key; poor tools can lead to poor results, and nobody wants that! Next, you’ll need to adjust the threading dial. This is like tuning a radio—get it right, and the magic happens. Check your tool height and ensure it matches the center line of the lathe. Don’t forget to secure your workpiece! Just think of it as securing your lunch; you don’t want it to roll away!

| Step | Description |

|---|---|

| 1 | Gather quality tools. |

| 2 | Adjust the threading dial carefully. |

| 3 | Match tool height to the center line. |

| 4 | Secure the workpiece tightly. |

The Role of the Threading Dial

Explanation of how the threading dial functions in the threading process.. Tips on using the threading dial for precise measurements..The threading dial is essential for creating precise threads on a lathe. It shows the correct position during the threading process. You can easily adjust it as you work. This helps you make accurate measurements, which is very important for a good fit. Here are some tips for using the threading dial:

- Always align the dial before starting.

- Make small adjustments for accuracy.

- Check the markings while threading.

These tips will help you achieve the best results.

Why is the threading dial important?

The threading dial helps you produce accurate threads. Without it, you might get uneven threads, making your project less effective.

Threading Techniques for Precision

Tips and techniques for achieving precise thread cutting.. Common pitfalls to avoid during the threading process..Using a lathe for threading can be a breeze, but there are some tricks to make your threads pull off a straight A! Start by checking the threading dial. Make sure it’s set just right, like a baking timer for perfect cookies! Avoid rushing; slow and steady wins the race. Common pitfalls include not using enough oil, which can make your metal parts grumpy. Remember, a happy lathe produces happy threads!

| Tip | Common Pitfall |

|---|---|

| Check your setup. | Skipping measurements. |

| Use plenty of oil. | Dry cuts can ruin threads. |

| Go slow! | Rushing leads to mistakes. |

Maintenance Tips for Lathe Threading Tools

Importance of maintaining threading tools for efficiency and longevity.. Recommended practices for tool upkeep and care..Taking care of your threading tools helps them last longer and work better. Poor maintenance can cause problems, making them less efficient. Here are some easy tips to keep your tools in great shape:

- Clean tools after use.

- Lubricate moving parts regularly.

- Check for wear and tear often.

- Store tools in a dry place.

- Follow manufacturer instructions closely.

Following these steps keeps your tools sharp and ready to use.

Why is tool maintenance important?

Proper maintenance boosts efficiency and extends the life of your lathe threading tools.

Safety Considerations in Lathe Threading

Essential safety protocols while operating a metal lathe.. Personal protective equipment (PPE) and workstation safety measures..Operating a metal lathe requires safety first. Always wear personal protective equipment (PPE) like goggles, gloves, and a face shield. This gear protects you from flying chips and sharp edges. Keeping your workspace organized is just as important. Ensure all tools are secure and clear of clutter. Here are a few tips:

- Check the lathe for any issues before use.

- Keep long hair tied back and avoid loose clothing.

- Always follow the machine’s manual for correct use.

Remember, safety helps everyone work better!

Why is PPE important while using a metal lathe?

PPE is crucial because it protects you from injuries caused by flying debris and hot metal. It can save you from cuts and burns, keeping you safe while you enjoy your work.

Common Problems and Troubleshooting in Lathe Threading

Identification of frequent issues encountered during threading.. Solutions and troubleshooting tips for common threading problems..Threading on a lathe can be tricky. Common issues include thread depth too shallow or uneven threads. Have you ever tried to measure a pizza but ended up with a pile of dough? It’s a bit like that! To fix these problems, first check the tool height. Adjust it until your threads look like a perfect spiral staircase, not a rollercoaster.

| Problem | Solution |

|---|---|

| Shallow Threads | Adjust tool height |

| Uneven Threads | Monitor feed rate |

Remember, proper matching between the lathe and threading dial is key. Clean your setup often. A clean lathe is like a happy dog—it works better! Following these tips can make threading smoother and keep your metal pieces as handsome as a shiny new penny.

Conclusion

In conclusion, using a lathe for threading creates precise metal parts. The threading dial helps you align cuts accurately. Remember to practice safely and patiently. You can create various threaded items for projects. Explore tutorials online to improve your skills. By using the right tools and techniques, you can become a confident metal lathe user. Happy threading!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And The Threading Dial:Sure! A lathe is a machine that helps shape metal or wood. The threading dial helps you make grooves or threads on the material. You turn the lathe on and then carefully move the tool to create the threads that fit together with other parts. It’s important to use the right settings on the threading dial for the best results. Always be careful and follow safety rules when using a lathe!

Sure! Please provide the question you’d like me to answer.

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In Producing Accurate Threads?A threading dial helps you cut threads on a metal lathe. It shows when to move the tool for the next cut. By using it, you can make sure the threads are evenly spaced and fit well together. This way, you get accurate and clean threads every time.

How Do You Properly Set Up A Metal Lathe For Threading Operations, Including Selecting The Correct Speed And Gear Ratios?To set up a metal lathe for threading, first, choose the right tool for cutting. Next, pick a speed that suits your material; usually, slower is better for threads. Then, adjust the gears to match the thread size you want. Finally, check everything is tight and safe before you start. Now you’re ready to make threads!

What Are The Differences Between Single-Point Threading And Tapping When Using A Metal Lathe?Single-point threading and tapping are both ways to create threads on metal. In single-point threading, you shape a long, spiral groove on the outside of the metal piece. With tapping, you make a hole with internal threads inside the metal. You use different tools for each job. Single-point threading is great for making custom sizes, while tapping is quick for creating holes to screw into.

What Are Some Common Mistakes To Avoid When Using The Threading Dial, And How Can They Affect The Quality Of Threads Produced?When using the threading dial, you should avoid setting it too early or too late. This can make your threads uneven. If you pull the thread too tight, it might break. Always check your thread before starting. This way, you can make nice, smooth stitches without problems.

How Do You Calculate The Correct Thread Pitch And Depth When Using A Metal Lathe For Creating Screw Threads?To calculate the thread pitch, you need to measure how far one thread goes in one full turn. We can do this by counting the threads in an inch, or using a special tool called a pitch gauge. For thread depth, you can use half the distance between the top and bottom of the threads. When you know these numbers, you can set your metal lathe to make the right threads.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And The Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal or wood. The threading dial helps you make grooves or threads on the material. You turn the lathe on and then carefully move the tool to create the threads that fit together with other parts. It’s important to use the right settings on the threading dial for the best results. Always be careful and follow safety rules when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In Producing Accurate Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you cut threads on a metal lathe. It shows when to move the tool for the next cut. By using it, you can make sure the threads are evenly spaced and fit well together. This way, you get accurate and clean threads every time.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe For Threading Operations, Including Selecting The Correct Speed And Gear Ratios?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for threading, first, choose the right tool for cutting. Next, pick a speed that suits your material; usually, slower is better for threads. Then, adjust the gears to match the thread size you want. Finally, check everything is tight and safe before you start. Now you’re ready to make threads!”}},{“@type”: “Question”,”name”: “What Are The Differences Between Single-Point Threading And Tapping When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Single-point threading and tapping are both ways to create threads on metal. In single-point threading, you shape a long, spiral groove on the outside of the metal piece. With tapping, you make a hole with internal threads inside the metal. You use different tools for each job. Single-point threading is great for making custom sizes, while tapping is quick for creating holes to screw into.”}},{“@type”: “Question”,”name”: “What Are Some Common Mistakes To Avoid When Using The Threading Dial, And How Can They Affect The Quality Of Threads Produced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the threading dial, you should avoid setting it too early or too late. This can make your threads uneven. If you pull the thread too tight, it might break. Always check your thread before starting. This way, you can make nice, smooth stitches without problems.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Correct Thread Pitch And Depth When Using A Metal Lathe For Creating Screw Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the thread pitch, you need to measure how far one thread goes in one full turn. We can do this by counting the threads in an inch, or using a special tool called a pitch gauge. For thread depth, you can use half the distance between the top and bottom of the threads. When you know these numbers, you can set your metal lathe to make the right threads.”}}]}