Have you ever watched a lathe spin? It’s fascinating! A lathe can shape metal, wood, and more. One of the most important jobs a lathe does is threading. But what is lathe threading? It’s a way to create spiral grooves on a piece of material. This helps parts fit together perfectly.

Imagine you are building a toy robot. You want the arms to twist and turn. This is where lathe threading comes in handy! Understanding how to do it step by step can open a world of creativity. Think about how cool it would be to make custom parts for your projects!

In this article, we will dive into the lathe threading operation step-by-step. With clear instructions, even beginners can learn this skill. Let’s explore how to turn a simple idea into a threaded masterpiece. Are you ready? Let’s get started!

Lathe Threading Operation Step-By-Step Guide Explained

Lathe Threading Operation: Step-by-Step

Lathe threading operation is an exciting skill to learn! This process lets you cut threads onto metal or plastic pieces easily. First, you prepare your lathe and choose the right tool. Then, you set the correct speed for a smooth operation. Next, you make precise measurements and adjust the tool to start threading. Finally, you check the threads for accuracy. Did you know that mastering this skill can open doors to many DIY projects?Understanding Lathe Threading Basics

Definition of lathe threading. Importance of threading in machining.Lathe threading describes the process of creating grooves or threads on a metal or wooden piece. This technique is vital in machining because it allows parts to fit together securely. Threads on screws, bolts, and tubes help them hold tightly when assembled. Without proper threading, machines may not work correctly, leading to malfunction or failure. Safe and efficient connections depend on threading. Understanding these basics helps everyone appreciate the role of threading in making strong and reliable products.

What is the purpose of threading in machining?

The purpose is to create secure connections between parts. It helps machines work better. Threads prevent loosening when vibrations occur. They also allow for easy assembly and disassembly of components.

Key Points about Threading:

- It aids in strength and stability.

- It ensures precise fit.

- It reduces wear and tear.

Types of Threads and Their Applications

Common types of threads (e.g., Metric, Imperial). Applications of different thread types in industries.There are many types of threads, and each serves a different purpose. The two most common types are metric and imperial. Metric threads use millimeters, while imperial threads use inches. These threads are found in various places.

- Metric Threads: Common in Europe for machinery and automotive parts.

- Imperial Threads: Found mainly in household items and some tools in the U.S.

Each type of thread is important and helps industries run smoothly. For example, metric threads are popular in engineering and construction, while imperial threads are often found in plumbing and electrical work.

What are the main uses of metric and imperial threads?

The main uses are in specific industries. Metric threads are mainly used in engineering and automotive fields, while imperial threads are popular in plumbing work.

Essential Tools and Materials for Threading

List of required tools (e.g., threading tool, calipers). Recommended materials for threading operations.To set up lathe threading, you’ll need some essential tools and materials. First on the list is a threading tool. This is your magic wand for creating threads. Next, grab a pair of calipers for measuring accuracy. Don’t forget the chuck to hold your workpiece in place, and some good cutting oil to keep things smooth. Here’s a quick summary in a handy table:

| Tools | Materials |

|---|---|

| Threading tool | Cutting oil |

| Calipers | Metal or plastic workpieces |

| Chuck | Threading inserts |

With these in hand, you’re ready to thread like a pro! Remember, it’s like baking—use the right ingredients for a perfect result!

Preparation for Lathe Threading

Steps for setting up the lathe machine. Safety precautions to consider.Before you start, make sure your lathe machine is ready. Here are some easy steps:

- Check tools: Ensure you have all the necessary tools.

- Clean the lathe: Keep the machine dirt-free.

- Secure the workpiece: Make sure it’s tight and safe.

Safety is super important! Remember to:

- Wear safety glasses.

- Use gloves to protect your hands.

- Keep long hair tied back.

Following these steps helps you stay safe while working!

What should I check before starting to thread?

Check your tool setup, workpiece security, and safety gear. Make sure everything is working properly before you begin.

Step-by-Step Lathe Threading Operation

Detailed instructions for starting the threading process. Techniques for maintaining accuracy during threading.To start the threading process on a lathe, follow these steps:

- Set the machine to the threading speed.

- Choose the correct tool bit for threading.

- Align the tool bit with the workpiece accurately.

- Engage the feed mechanism smoothly.

To maintain accuracy, try these techniques:

- Check your measurements frequently.

- Adjust the tool height to match the workpiece.

- Keep the lathe clean and free from debris.

Remember, practice makes perfect! Threading can be tricky, but with careful steps, you can achieve great results.

What is threading in lathe operations?

Threading in lathe operations is creating grooves on a cylindrical workpiece. It’s often used to make screws or bolts.

Common Questions:

- What tools do I need for threading? You need a lathe machine, a threading tool, and measuring tools.

- How do I avoid mistakes in threading? Always measure twice and operate slowly.

Troubleshooting Common Issues in Threading

Identification of common threading problems (e.g., chip buildup). Solutions to fix threading issues and improve quality.Threading troubles can make any machinist frown. One common issue is chip buildup. When chips pile up, they can harm your threading quality. Another problem is uneven threads, which can occur due to incorrect speed or feed rate. To fix these issues, ensure tools are sharp and adjust your speed. Remember, happy tools make happy threads! Check your settings often, and you’ll be threading like a pro in no time.

| Issue | Solution |

|---|---|

| Chip Buildup | Clear chips frequently and use proper coolant. |

| Uneven Threads | Adjust speed and feed rate. |

Maintenance Tips for Lathe Threading Tools

Importance of tool maintenance for longevity. Recommended practices for tool care and storage.Taking care of your lathe threading tools is a must! Regular maintenance keeps them sharp and happy, boosting their lifespan. Imagine a tool like a superhero; it needs its rest and care to keep fighting your threading battles. Here are a few golden rules:

| Practice | Description |

|---|---|

| Clean Them | Always wipe off chips and dust after use. Dirty tools get cranky! |

| Store Safely | Keep them in a dry place, away from moisture. No one likes a soggy tool! |

| Regular Inspections | Check for wear and tear. A stitch in time saves nine! |

Following these tips will help your tools last longer and work better. Remember, happy tools make for a happy workshop!

Resources for Further Learning

Recommended books and online courses on lathe threading. Relevant forums and communities for machinists.Want to dive deeper into the world of lathe threading? Grab some recommended books and check out online courses. You’ll find gems like “Machining Fundamentals” and courses on platforms like Udemy that make learning fun! Don’t forget to join lively forums like the Machinist Forum. It’s a great place to ask questions and swap funny stories. You might even learn a trick or two while sharing a laugh!

| Resource Type | Recommended Resources |

|---|---|

| Books | Machining Fundamentals, The Complete Guide to Metalworking |

| Online Courses | Udemy, Coursera |

| Forums | Machinist Forum, Reddit’s r/Machinists |

Conclusion

In summary, lathe threading is a useful skill. It involves key steps: setting up your lathe, selecting tools, and cutting threads carefully. Each part is essential for smooth operation. Remember, practice helps you master threading. We encourage you to try threading on a small project next. For more tips and techniques, keep reading guides or watch online videos. Happy threading!FAQs

Here Are Five Related Questions On The Topic Of Lathe Threading Operation:Sure! Please provide the questions from the “Here are five related questions on the topic of lathe threading operation” section, and I’ll be happy to answer them.

Sure! Please provide the question you’d like me to answer, and I’ll help you with it.

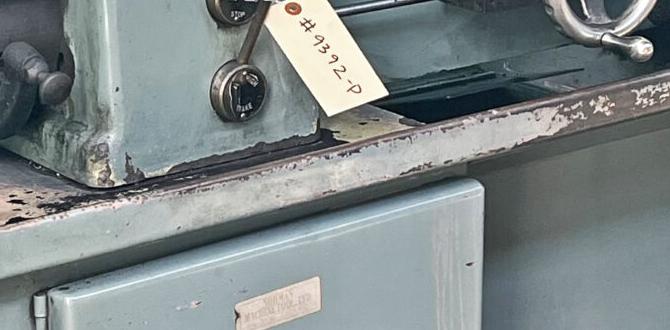

What Are The Essential Components Of A Lathe Used For Threading Operations?A lathe used for threading has a few important parts. First, there’s the spindle, which holds the workpiece. Next, we have the tool post, where the cutting tool is attached. The carriage moves the tool along the workpiece. Finally, the tailstock helps support the other end of the workpiece. These parts work together to make threads on metal or wood.

How Do You Calculate The Thread Pitch And Depth When Setting Up A Lathe For Threading?To calculate thread pitch, you count the number of threads in one inch. For example, if there are 10 threads in that inch, the thread pitch is 10. To find the depth, we usually take a third of the pitch. So, if the pitch is 10, the depth would be about 3.333, which is one-third of 10. You can then set the lathe with these measurements for good threading.

What Steps Are Involved In Properly Aligning The Workpiece In The Lathe Before Beginning The Threading Process?To align the workpiece in the lathe, first, you need to put the piece in the center of the machine. Make sure it’s tight and won’t move. Next, check that the tailstock is close to the end of the piece. Use a ruler or caliper to measure the ends and see if they are even. Lastly, turn on the lathe slowly to ensure everything spins straight before you start threading.

How Do You Select The Appropriate Cutting Tool And Speed Settings For Threading Different Materials On A Lathe?To pick the right cutting tool for threading, you need to know what material you are using. For soft materials like aluminum, use a sharper tool. For hard materials like steel, choose a stronger tool. Speed settings also depend on the material; softer materials need faster speeds, while harder ones go slower. Always check the machine’s manual for best practices!

What Safety Precautions Should Be Taken During Lathe Threading Operations To Ensure A Safe Working Environment?To stay safe while using a lathe for threading, we should always wear safety goggles to protect our eyes. Keep hands and loose clothing away from moving parts. Make sure to keep the workspace clean and free of clutter. It’s also important to follow the machine’s instructions and ask for help if unsure. Lastly, always use the right tools for the job.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Threading Operation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the questions from the Here are five related questions on the topic of lathe threading operation section, and I’ll be happy to answer them.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll help you with it.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Lathe Used For Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe used for threading has a few important parts. First, there’s the spindle, which holds the workpiece. Next, we have the tool post, where the cutting tool is attached. The carriage moves the tool along the workpiece. Finally, the tailstock helps support the other end of the workpiece. These parts work together to make threads on metal or wood.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Thread Pitch And Depth When Setting Up A Lathe For Threading?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate thread pitch, you count the number of threads in one inch. For example, if there are 10 threads in that inch, the thread pitch is 10. To find the depth, we usually take a third of the pitch. So, if the pitch is 10, the depth would be about 3.333, which is one-third of 10. You can then set the lathe with these measurements for good threading.”}},{“@type”: “Question”,”name”: “What Steps Are Involved In Properly Aligning The Workpiece In The Lathe Before Beginning The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the workpiece in the lathe, first, you need to put the piece in the center of the machine. Make sure it’s tight and won’t move. Next, check that the tailstock is close to the end of the piece. Use a ruler or caliper to measure the ends and see if they are even. Lastly, turn on the lathe slowly to ensure everything spins straight before you start threading.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Cutting Tool And Speed Settings For Threading Different Materials On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right cutting tool for threading, you need to know what material you are using. For soft materials like aluminum, use a sharper tool. For hard materials like steel, choose a stronger tool. Speed settings also depend on the material; softer materials need faster speeds, while harder ones go slower. Always check the machine’s manual for best practices!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During Lathe Threading Operations To Ensure A Safe Working Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stay safe while using a lathe for threading, we should always wear safety goggles to protect our eyes. Keep hands and loose clothing away from moving parts. Make sure to keep the workspace clean and free of clutter. It’s also important to follow the machine’s instructions and ask for help if unsure. Lastly, always use the right tools for the job.”}}]}