Have you ever watched a lathe in action? It’s fascinating to see how a small piece of metal turns into a finely threaded part. But did you know that the secret lies in the lathe threading tool geometry?

The shape and angles of the threading tool make a huge difference. Imagine trying to cut cake with a dull knife. It just doesn’t work well, right? The same goes for threading tools. They need to be sharp and well-shaped to do their job effectively.

Many people don’t realize how important geometry is in this process. It’s like a puzzle where every piece matters. If the tool isn’t designed correctly, the threads may end up uneven or weak.

In this article, we will explore the world of lathe threading tool geometry. From shapes to angles, we’ll uncover the key elements that help create precise threading. Get ready to dive into the details and learn what makes a great threading tool!

Understanding Lathe Threading Tool Geometry For Precision Machining

Lathe Threading Tool Geometry

Understanding lathe threading tool geometry is key for precision machining. These tools have specific shapes to cut threads accurately on metal or wood. Did you know the angle of the tool affects thread quality? A better angle can lead to stronger threads. Also, the tool’s height matters; it should match the workpiece to ensure smooth operation. Knowing this geometry can turn a good project into a great one. Isn’t it fascinating how such small details can make a big difference?Understanding Lathe Tool Geometry

Definition of tool geometry in lathe machining. Importance of proper tool geometry for machining efficiency.Tool geometry in lathe machining refers to the shape and angles of the cutting tool. This design impacts how effectively the tool cuts the material. Proper tool geometry is crucial for achieving smooth and efficient machining. It can lead to better surface finishes and longer tool life. When the geometry is right, machines work faster and waste less material. This means higher productivity and lower costs for everyone!

Why is Tool Geometry Important?

Proper tool geometry helps machines work better and save money.

- It ensures accurate cuts.

- It provides better durability.

- It reduces wear on tools.

- It improves surface quality.

Key Geometric Features of Lathe Threading Tools

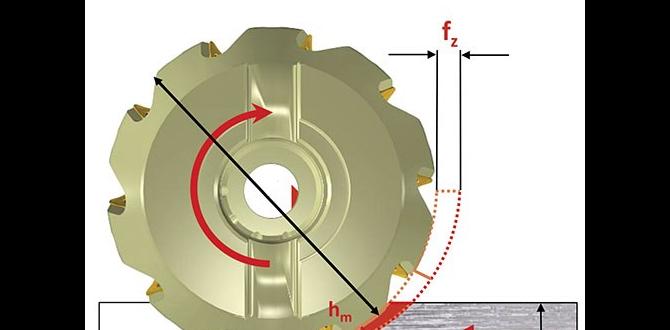

Cutting edge angle and its impact on threading. Flank angle and its significance in material removal.Understanding lathe threading tool geometry is fun and useful! One key point is the cutting edge angle. This angle impacts how smoothly the tool cuts through materials. A sharper angle can slice like a hot knife through butter, reducing effort. Also, the flank angle is important. It helps the tool remove material effectively. If the angle is wrong, it might struggle, making you feel like you’re pushing a boulder uphill!

| Feature | Impact |

|---|---|

| Cutting Edge Angle | Improves cutting ease and efficiency. |

| Flank Angle | Ensures smooth material removal. |

Parameters Affecting Lathe Tool Performance

Effects of rake angle on cutting forces. Influence of clearance angle on surface finish.The angles of a lathe tool can greatly change how it works. A tool’s rake angle affects the cutting forces. With a larger rake angle, the cutting forces become less. This makes it easier to cut through materials. It can help save energy and reduce wear on the tool.

The clearance angle is just as important. A correct clearance angle helps make a smooth surface finish. If the angle is wrong, it can create scratches or rough spots. This affects the quality of the finished product.

How does the rake angle impact cutting forces?

A larger rake angle reduces cutting forces. This makes it easier to cut materials and saves energy.

What role does clearance angle play in surface finish?

- Correct angles create smooth surfaces.

- Wrong angles can scratch materials.

Tool Material and Coating Considerations

Common materials used for threading tools. Benefits of coatings for durability and wear resistance.Choosing the right material for a threading tool is like selecting the perfect ice cream flavor—you want it to last and not melt away! Common materials include high-speed steel (HSS) and carbide. HSS is tough but may wear quickly, while carbide lasts longer and handles heat well. Coatings can be game-changers too. They protect against wear and tear like sunscreen for your tools. Some popular coatings are titanium nitride (TiN) and titanium carbonitride (TiCN), adding a sparkle and strength. Check this out:

| Material | Benefits |

|---|---|

| High-Speed Steel (HSS) | Good toughness, cheaper |

| Carbide | Long-lasting, heat-resistant |

| Titanium Nitride (TiN) | Increases hardness, reduces friction |

| Titanium Carbonitride (TiCN) | Great for aluminum, boosts wear resistance |

With the right choices, your threading tools can work like superheroes. They’ll save the day, creating threads without wearing out too soon!

Setting Up Lathe Tool Geometry for Threading

Guidelines for adjusting tool position and angles. Importance of accurate measurements for precision work.Setting the right tool angles and positions is key for threading on a lathe. Small changes can make a big difference. Remember to:

- Use a precise measuring tool for accurate setup.

- Check your angles—small tweaks can improve performance.

- Keep the tool steady; stability is crucial.

Accurate measurements lead to precise work. Precision means better threads and smooth operations. Happy threading!

Why is accurate lathe tool geometry important?

Proper lathe tool geometry ensures correct thread dimensions and smooth finishes. This makes your project both safe and effective.

Maintenance Tips for Threading Tools

Best practices for tool inspection and maintenance. Importance of regular sharpening and replacement.Keeping threading tools in top shape is key to great results. Start with regular inspections; think of it like checking your shoes for holes. Look for nicks or chips—these can mess up your work. Sharpen tools regularly, like your favorite pencils but without the chewing. If they’re too worn, it’s time to replace them, or you might end up with threads that resemble spaghetti instead of precision. Remember, a sharp tool is a happy tool!

| Maintenance Task | Frequency |

|---|---|

| Tool Inspection | Every Use |

| Sharpening | As Needed |

| Replacement | When Damaged |

Advanced Threading Techniques and Innovations

Exploration of CNC threading tool geometry. Future trends in threading tool technology.New techniques in CNC threading tools are changing the way we work. CNC stands for computer numerical control, making the process much easier and precise. Innovations in threading tool geometry allow for stronger, more efficient cuts. In the future, tools will be faster and smarter. They will use sensors to gather data. This data helps make threading more accurate. Are you ready for these exciting changes?

What are the future trends in threading tool technology?

Future trends include smarter tools, better materials, and more automation. These advancements will improve efficiency and reduce waste.

Future Technologies in Threading:

- Use of artificial intelligence for better designs

- Advanced materials for longer-lasting tools

- Enhanced automation for faster production

Conclusion

In conclusion, lathe threading tool geometry shapes how well the tool cuts. Knowing the right angles and shapes gives better thread quality. When you understand these basics, you can improve your lathe projects. Remember, practice makes perfect! Explore more resources or videos online to see these tools in action. Happy learning and happy turning!FAQs

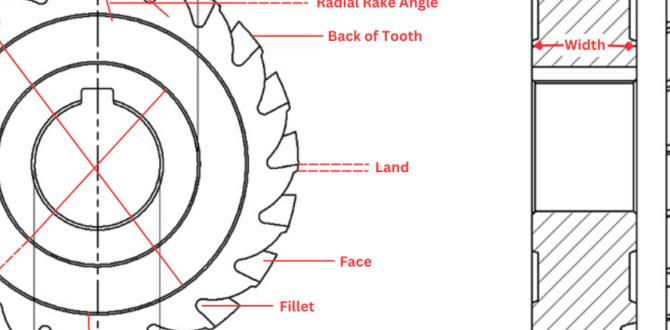

What Are The Key Geometric Features Of A Lathe Threading Tool That Influence Its Cutting Performance And Accuracy During The Threading Process?A lathe threading tool has some important shapes that help it cut better. The pointy tip helps start the cut precisely. The tool’s angle creates a strong edge that digs into the metal as it spins. The width of the tool matters too; it should match the thread size we want. Overall, these features help us make accurate and clean threads on our workpiece.

How Does The Tool Angle, Such As The Approach Angle And Relief Angle, Affect The Chip Formation And Surface Finish When Creating Threads On A Lathe?The tool angle affects how the tool cuts the material. A good angle helps the tool slice easily, making smooth chips. When the chips are clean, the surface looks nicer. If the tool angle is wrong, it can leave rough marks. So, using the right angles gives you stronger threads and a better look!

In What Ways Does The Choice Of Threading Tool Material And Geometry Impact The Tool’S Durability And Wear Resistance During Extended Use?The choice of material affects how strong and tough the tool is. For example, harder materials last longer and resist damage better. The shape, or geometry, of the tool can help it cut smoother. A good shape means less friction, which helps it stay sharp. Using the right material and shape makes the tool last longer when you use it a lot.

How Can Adjusting The Cutting Edge Geometry Of A Threading Tool Improve Thread Quality And Reduce The Likelihood Of Tool Failure During Operation?When you change the shape of the cutting edge on a threading tool, it can make better threads. This helps the tool cut more smoothly and reduce wear. A smoother cut means the tool lasts longer and doesn’t break as easily. Better shapes help the tool handle heat and pressure, which keeps it working well. Overall, good designs make threading easier and safer!

What Are The Recommended Dimensions And Clearances For A Threading Tool To Ensure Optimal Performance For Different Thread Pitches And Materials?To make threading tools work best, we need to pay attention to their size and space around them. Generally, the tool should be slightly smaller than the thread size. You also want a little gap, called clearance, to help it move easily. For different threads, make sure this space is just right for both tight and loose threads. Proper sizes and clearances help you cut threads cleanly and smoothly.