Lathe Tool Bit Breakage Causes: Understanding The Factors

Lathe Tool Bit Breakage Causes

Tool bit breakage on a lathe is frustrating but common. It often happens due to excessive pressure or speed that the tool can’t handle. Improper tool alignment can lead to uneven wear and breaks. Did you know using dull bits increases the risk of breakage? Keeping tools sharp helps maintain performance. Regular inspections and adjustments can prevent many issues. Understanding these causes can save both time and money in the workshop. Don’t let tool breakage slow you down!Common Causes of Lathe Tool Bit Breakage

Material properties leading to breakage, including hardness and brittleness.. Effects of improper tool geometry on durability and performance..Breakage of lathe tool bits can happen for a few reasons. First, the material of the tool matters. If it’s too hard or too brittle, it might snap like a twig! Hardness helps cut well, but if the tool is too fragile, it breaks easily. Next, improper tool geometry can ruin the party. A badly shaped tool can wear out fast, losing its superpowers and ruining your work. Remember, the right tool for the job is like finding the perfect slice of pizza—necessary!

| Cause | Description |

|---|---|

| Material Hardness | Too hard can break; too soft won’t cut. |

| Brittleness | Brittle tools snap under pressure. |

| Improper Geometry | Poor shapes lead to quick wear and breakage. |

Operational Factors Leading to Breakage

The impact of cutting speed and feed rate on tool wear.. Importance of coolants and lubrication in preventing overheating..Cutting speed and feed rate are like the “Goldilocks” of machining. Too high or too low can wear down tools quickly, leading to breakage. The sweet spot helps tools last longer. Proper cooling and lubrication also play a vital role. They keep everything from overheating. Without them, machines can turn into “melting pots” instead of working tools. So remember, keep things cool, and your tools will thank you!

| Factor | Impact on Tool Wear |

|---|---|

| Cutting Speed | Too fast = quick wear |

| Feed Rate | Keeping it moderate extends life |

| Coolants | Prevents overheating |

| Lubrication | Reduces friction |

Environmental Influences on Tool Bit Longevity

Role of workpiece material and its characteristics in tool life.. Effects of machining conditions such as temperature and humidity..Every material used in machining has unique traits that affect tool life. Harder materials can wear down tools faster, while softer ones may not. Also, temperature and humidity matter a lot. High heat can cause tools to break, while moisture can lead to rust. Understanding these factors helps in choosing the right tool and workpiece, extending the tool’s lifespan.

How do workpiece materials affect lathe tool bits?

Workpiece materials determine the pace of tool wear. For example, metals like steel need stronger tools than softer woods. Using the right tool can help prevent breaks and extend life.

What machining conditions impact tool bit longevity?

- High temperatures: Can make tools brittle.

- High humidity: Can cause rust.

- Low temperatures: May lead to tool failure.

Preventative Measures to Reduce Breakage

Best practices in tool selection and maintenance strategies.. Techniques for optimizing machining parameters to enhance tool performance..Keeping your lathe tool bits safe is like giving them a comfy blanket and a snack! Start by choosing the right tool. Quality matters. A well-made bit lasts longer, reducing the chance of breakage. Regular maintenance helps too. Clean and check tools often. Stay sharp—literally! Keep your bits aligned properly to avoid drama during machining. Adjusting speed and feed can be the difference between smooth sailing and a bumpy ride.

| Best Practices | Tips |

|---|---|

| Tool Selection | Choose high-quality bits. |

| Maintenance | Regular cleaning and checks. |

| Machining Parameters | Optimize speed and feed. |

Remember, a happy lathe means fewer breakages and more fun! So, treat your tools well, and they’ll reward you with performance and longevity.

Identifying Signs of Tool Wear and Potential Breakage

Indicators that suggest a lathe tool is nearing failure.. Importance of routine inspections and monitoring..Watch for signs that your lathe tool is reaching its end. If you notice a strange sound, increased vibrations, or a rough finish, it might be time for a change. Dull tools don’t just make bad art; they can also break! Regularly checking your tools is very important. Think of it as a check-up for your machines—they can’t tell you when they’re feeling under the weather. Keeping an eye on your lathe can save you time and money.

| Signs of Tool Wear | Action Needed |

|---|---|

| Strange noises | Inspect immediately |

| Increased vibrations | Replace or sharpen |

| Rough surface finish | Check tool sharpness |

Keep your tools healthy! After all, a happy lathe is a productive lathe. Remember, an ounce of prevention is worth a pound of cure.

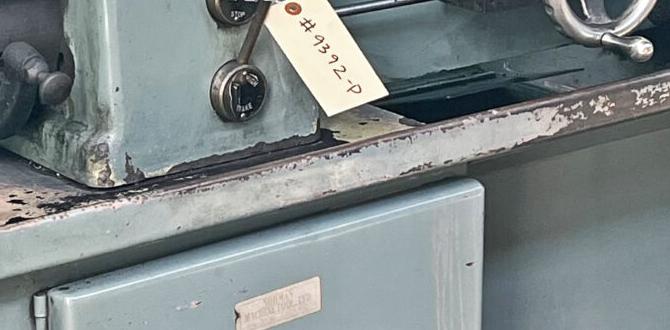

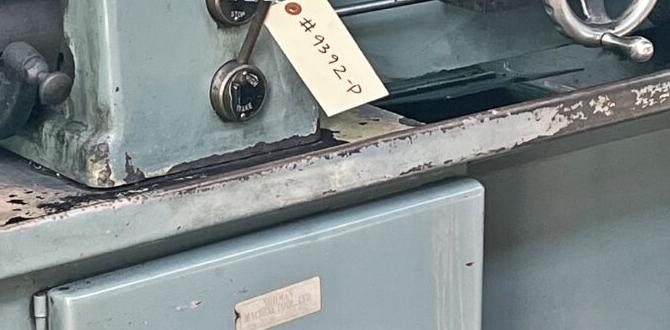

Case Studies and Real-World Examples

Analysis of specific scenarios leading to tool bit failures.. Lessons learned and modifications implemented for improved outcomes..In real-life situations, lathe tool bits can break for several reasons. Understanding these cases helps prevent future problems. Here are some key points:

- Improper Speed: A too-fast rotation can cause breakage.

- Wrong Material: Using the wrong tool for specific materials weakens the bit.

- Wear and Tear: Old bits can break easily.

After analyzing these issues, companies made changes. They adjusted speeds, chose better materials, and replaced worn tools. As a result, they saw fewer breakages.

What causes lathe tool bit breakage?

Lathe tool bit breakage often results from improper speed settings, incorrect material use, and wear and tear on the tools.

Conclusion

In summary, lathe tool bit breakage can happen for several reasons. Common causes include dull tools, excessive speed, and wrong materials. To avoid breakage, always check your tools and settings. You can improve your skills by practicing and learning more about lathe operations. We encourage you to explore these topics and keep your projects running smoothly!FAQs

Certainly! Here Are Five Questions Related To The Causes Of Lathe Tool Bit Breakage:Some causes of lathe tool bit breakage include using dull tools, pushing too hard, or working too fast. If you don’t keep the tool clean, it can also break. Using the wrong tool for the job can cause problems too. Lastly, if the tool gets too hot, it can snap. Always remember to take your time and check your tools!

Sure! Please provide the question you’d like me to answer, and I’ll help you with it.

What Are The Primary Factors Contributing To Tool Bit Breakage During Lathe Operations?Tool bit breakage in lathe operations can happen for a few reasons. First, too much pressure on the tool can cause it to snap. Second, using a dull tool makes it harder to cut, leading to breakage. Third, cutting at the wrong speed can create stress on the tool. Lastly, not using the right type of tool for the job can cause it to break, too.

How Does Improper Tool Bit Selection Affect Its Performance And Longevity On A Lathe?If you pick the wrong tool bit for the lathe, it won’t work well. It might get dull quickly or break easily. A poor choice can also make your projects messy. This means you will have to fix things more often, wasting time and materials. Overall, the tool won’t last as long as it should.

In What Ways Can Cutting Speed And Feed Rate Influence The Likelihood Of Tool Bit Breakage?Cutting speed is how fast we move the tool against the material. If it’s too fast, the tool can get too hot and break. Feed rate is how much material we take away with each cut. If you cut too much at once, it can stress the tool and cause it to snap. Using the right speed and feed helps keep the tool safe and working well.

What Role Does Tool Bit Material And Geometry Play In Preventing Or Causing Breakage?The material of a tool bit affects how strong it is. Some materials are tougher and can handle more pressure without breaking. The shape, or geometry, of the tool bit also matters. A sharp edge can cut better, while a dull edge might chip or break. By choosing the right material and shape, we can prevent breakage and help the tools last longer.

How Can Operator Technique And Machine Maintenance Practices Minimize The Risk Of Tool Bit Failure On A Lathe?To prevent tool bits from breaking on a lathe, you need to use the machine carefully. First, always check if the tool bit is sharp and clean before using it. Regularly maintain the lathe by keeping it oiled and tight to avoid problems. Also, follow proper rules when changing the tool bits. This way, we can help the tool last longer and work better.