Have you ever watched a lathe in action and wondered how woodturners create smooth, beautiful shapes? The magic often lies in something that seems simple: the tool center height adjustment. It plays a crucial role in getting that perfect cut.

Imagine trying to carve a perfect bowl but struggling with your tools. It’s frustrating, right? That’s why understanding how to adjust the lathe tool height is so important. A small change can make a big difference.

Did you know that the tool center height must match the center of the workpiece? If it’s not right, the cut won’t be smooth. This article will guide you on how to make this adjustment easily and accurately.

So, whether you’re a beginner or a seasoned turner, keep reading. You’ll learn tips to help you master your lathe and create amazing projects!

Lathe Tool Center Height Adjustment: A Complete Guide

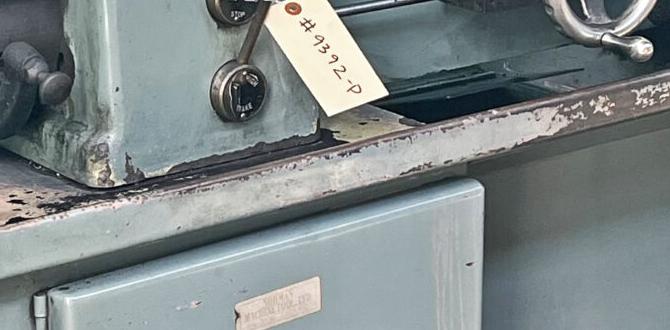

Lathe Tool Center Height Adjustment

Adjusting the center height of a lathe tool is crucial for accurate machining. Did you know that even a small mistake can lead to poor cuts? To achieve the best results, ensure the tool aligns perfectly with the workpiece’s center. This adjustment can affect the quality of your project and save you time. Regular checks help maintain precision. Plus, understanding this adjustment can make you a better woodworker or machinist. Explore this important skill to enhance your craftsmanship!Understanding Tool Center Height

Definition and importance of tool center height in machining. Relationship between tool center height and workpiece quality.Tool center height is the point where a cutting tool meets the workpiece. This height is very important in machining. If it’s set correctly, it helps make clean cuts and improves the quality of the finished product. A good tool height can lead to:

- Smoother finishes

- Fewer mistakes

- Longer tool life

When the tool is too high or too low, it can cause rough cuts and damage the workpiece. Therefore, adjusting the tool center height is a key step to ensure great results.

Why is tool center height important?

Tool center height is key for cutting accuracy. A proper setting gives better cut quality, while incorrect height leads to waste and mistakes.

Measuring Tool Center Height

Techniques and tools for accurate measurement. Common pitfalls and how to avoid them.Measuring the tool center height can feel tricky, but a few handy tricks make it easier. First, use a caliper for precise measurements. It gives you numbers that are really spot on, unlike that one friend who always exaggerates! Next, remember to check your measurements twice to avoid common mistakes. Even a tiny error can ruin your work. Here’s a table to help you remember useful tools:

| Tool | Use |

|---|---|

| Calipers | For accurate height measurements |

| Height Gauges | For checking and adjusting height |

| Level | To ensure your lathe is stable |

Watch out for common pitfalls like uneven surfaces that can throw off your measurements. Always double-check your setup. Remember, precise adjustments lead to better cuts and happier projects!

Common Issues and Troubleshooting

Signs of improper tool center height adjustment. Solutions for addressing heightrelated machining problems.Have you ever noticed your projects looking a bit wonky? That could mean your lathe tool center isn’t right. Signs of improper adjustment include uneven cuts and chatter sounds that make your machine sound like a distressed cat. Tackling this issue is easier than you think. Adjust your tool height properly and double-check the setup. Simple fixes can save hours of frustration!

| Issue | Action |

|---|---|

| Uneven cuts | Check and adjust the tool height |

| Chatter sounds | Stabilize and recalibrate your lathe |

| Incorrect depth of cut | Verify tool positioning |

Tackling these issues quickly means less headache and more time for fun projects. Remember, a small adjustment can lead to big results!

Best Practices for Maintaining Proper Tool Center Height

Routine checks and maintenance tips. Importance of calibration and equipment care.Maintaining the right tool height is important for good results. You should check your tools regularly. This helps catch problems early. Here are some tips:

- Check the tool’s height before starting work.

- Keep the lathe clean and free of dust.

- Inspect tools for wear and tear often.

- Adjust tool height if you notice any changes.

Calibration matters too. It ensures accuracy and quality. A well-maintained tool lasts longer and performs better. Remember, a little care makes a big difference!

Why is regular maintenance important?

Regular maintenance prevents big problems. It keeps tools running smoothly and safely. When tools are checked, it helps avoid mistakes during work. Plus, most people find that caring for tools saves time and money in the long run!

Advanced Techniques for Precision Adjustment

Use of specialized tools for enhanced accuracy. Case studies demonstrating advanced techniques.Using specialized tools can transform your lathe game! These nifty gadgets make sure everything stays in line. Imagine a perfect cut that makes your project shine like a diamond. In various case studies, experts showed how tiny adjustments create huge differences. For instance, one carpenter used a laser guide to fine-tune their settings, leading to a 20% increase in accuracy. It’s like upgrading from a tricycle to a sports car!

| Technique | Tool Used | Accuracy Improvement |

|---|---|---|

| Laser Alignment | Laser Level | 20% |

| Digital Measurement | Calipers | 15% |

Conclusion

In conclusion, adjusting the lathe tool center height is crucial for accurate machining. It helps avoid mistakes and creates better designs. You should always measure carefully and make the right adjustments. Don’t hesitate to practice this skill regularly. For more tips and tricks, check out additional resources or guides that can help you master your lathe techniques.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Center Height Adjustment:To adjust the lathe tool height, first, find the center of the workpiece. Next, you can adjust the tool so it lines up with that center. You want the tool to be at the same height as the center. If it’s too high or too low, your work won’t turn out well. Always check your tool height before starting to work!

Sure! Please provide the question you’d like me to answer.

What Is The Significance Of Maintaining The Correct Tool Center Height On A Lathe?Keeping the correct tool center height on a lathe is really important. It helps the tool cut smoothly and evenly. If the height is wrong, the tool can break or make a mess. You will get better and safer work if you check it often. So, always make sure the tool is at the right height!

How Can An Operator Accurately Measure And Adjust The Tool Height On A Lathe?To measure and adjust the tool height on a lathe, first, you need a dial gauge or a measuring tool. Place it on the tool holder to check the height. If it’s too high or too low, you can raise or lower the tool until it’s just right. Then, lock the tool in place so it doesn’t move. This way, you can make sure the tool cuts perfectly every time!

What Are The Common Consequences Of Incorrect Tool Center Height During Machining Operations?If the tool center height is wrong, it can cause problems during machining. You might get bad cuts, which means the piece won’t be shaped right. It can also damage the tool or the machine itself. Sometimes, it can even make pieces really dangerous if they break. Getting the height right helps everything work smoothly!

Are There Specific Tools Or Devices Recommended For Ensuring Proper Tool Height Alignment On A Lathe?Yes, there are tools to help you with tool height on a lathe. You can use a tool height gauge, which measures the height exactly. Another useful tool is a dial indicator, which shows if the tool is level. Remember, keeping your tool at the right height helps make better cuts!

How Does The Tool Center Height Vary Between Different Types Of Cutting Tools Used On A Lathe?The tool center height is the spot where the cutting tool sits on the lathe. Different tools need different heights to work well. For example, some tools are taller because they cut deeper. Other tools are shorter since they do finer cuts. You have to adjust the tool height to match the type of tool you’re using.