Have you ever seen a lathe tool in action? It’s fascinating how metal can be shaped with precision. Lathe tool grinding is a crucial part of this process. But what if it could be done faster and more accurately? That’s where metal lathe automation steps in.

Imagine a workshop where machines do most of the hard work. Workers can focus on other tasks instead of grinding tools by hand. This not only saves time but also improves the quality of work. Did you know that automated lathes can create perfectly shaped parts with little effort? That’s an exciting change in the world of machining!

In this article, we’ll explore how lathe tool grinding and metal lathe automation work together. We’ll discover how these advancements can help industries meet rising demands. Get ready to dive into this innovative world!

Lathe Tool Grinding: Enhancing Metal Lathe Automation Efficiency

Lathe Tool Grinding: Metal Lathe Automation

Grinding lathe tools is crucial for precise metalworking. Automated systems enhance efficiency, reducing the time workers spend on manual tasks. Automation helps achieve consistent results and improves safety in the workshop. Imagine tackling complex designs with ease! Did you know that modern metal lathes can perform tasks that took hours in just minutes? Learning about lathe tool grinding can boost your skills and open doors in metal fabrication. It’s an exciting journey in the world of machinery!Understanding Lathe Tool Grinding

Definition and purpose of lathe tool grinding. Importance in metalworking and machining processes.Lathe tool grinding is the process of sharpening and shaping the cutting tools used on a lathe. This ensures that tools work efficiently, cutting metal smoothly. Think of it as giving your tools a fresh haircut to make them shiny and sharp! Good grinding improves accuracy in metalworking. Fun fact: It can even make your tool last longer—like keeping your favorite toy in great shape instead of letting it gather dust!

| Purpose of Lathe Tool Grinding | Importance in Metalworking |

|---|---|

| Sharpens cutting edges | Ensures smooth operation |

| Shapes tools for specific tasks | Improves accuracy |

| Extends tool life | Reduces waste and costs |

Sharpen those tools, and your metalwork will shine brighter than the sun on a summer day!

The Process of Lathe Tool Grinding

Stepbystep breakdown of the grinding process. Essential tools and machines used in grinding.Grinding tools follows a simple dance of steps. First, you set up the lathe machine. Next, choose your grinding wheel and fix it on the grinder. Then comes the fun part, grinding the tool itself! You slowly move the tool against the wheel, sharpening it like a chef with a knife. Essential tools include the lathe, grinding wheel, and measuring instruments. Remember, precision is key—don’t get your tools mixed up, or you might end up with a spoon instead of a chisel!

| Step | Action |

|---|---|

| 1 | Set up the lathe machine. |

| 2 | Choose and fix the grinding wheel. |

| 3 | Grind the tool carefully. |

Advantages of Automated Lathe Tool Grinding

Increased efficiency and precision in production. Reduced labor costs and error rates.Automated lathe tool grinding offers many benefits. It makes production quicker and more precise. Machines work faster than people, which boosts efficiency. This means more items can be made in less time. Also, machines don’t get tired, so the error rate is much lower. This reduces the need for many workers, cutting labor costs.

- Increased speed of production

- Higher accuracy in cuts

- Less wasted material

- Fewer mistakes to fix

What are the benefits of automated lathe tool grinding?

Automated lathe tool grinding leads to faster production, lower errors, and less need for workers.

Challenges in Lathe Tool Grinding Automation

Common issues faced during the automation process. Solutions and best practices to overcome these challenges.Automating lathe tool grinding has many challenges. Common issues include inconsistent tool quality and machine errors. These problems can slow down production and increase costs. To tackle these, it helps to:

- Regularly maintain machines for better performance.

- Use quality sensors for accurate measurements.

- Train staff to understand automation systems.

These solutions can help improve efficiency. With the right tools and practices, you can overcome obstacles in lathe tool grinding.

What are common challenges in lathe automation?

Common challenges include tool wear, inaccurate measurements, and system breakdowns. Proper maintenance and skilled operators can help greatly.

Best practices for automation

- Implement routine checks for machines.

- Invest in advanced technology for precision.

- Develop training programs for staff.

Future Trends in Lathe Tool Grinding and Automation

Emerging technologies and their potential impact. Predictions for the future of metalworking automation.New tools are changing how we grind lathe tools. Machines can now do more work with less effort. Robots are being used to help make parts faster and more accurately.

- Artificial Intelligence helps machines learn and improve.

- 3D printing can create unique tool shapes quickly.

- Sensors can check for problems during work.

What are the future trends in metalworking automation?

Future trends include smarter robots, better sensors, and advanced software. These tools will make work easier and keep products safe.

Maintenance and Best Practices for Automated Lathe Tool Grinding

Importance of maintaining grinding machines for longevity. Tips for optimal operation and safety.Keeping your grinding machine in tip-top shape is like giving it a spa day! Regular maintenance helps extend the life of your lathe tools, ensuring they work efficiently. For optimal operation, always check for any signs of wear and tear. Safety first! Don’t forget your goggles! A well-maintained machine runs smoother and quieter, almost like it’s singing a happy tune. Remember, a clean workspace also means less chance of accidents. Have fun grinding!

| Maintenance Tips | Safety Measures |

|---|---|

| Regularly clean and inspect tools | Wear protective gear |

| Lubricate moving parts | Keep the area tidy |

| Calibrate settings regularly | Know emergency shutdown procedures |

Case Studies: Successful Implementation of Lathe Tool Grinding Automation

Realworld examples of businesses that improved efficiency. Lessons learned and outcomes achieved.Many businesses have successfully automated lathe tool grinding. These companies saw big improvements in their work. For example, a small factory increased output by 40% after automation. They saved time and reduced errors. Another large company cut costs by 30% using automated grinding systems. This made them more competitive. They learned that investing in technology pays off.

- Increased efficiency

- Reduced costs

- Fewer mistakes

What are the benefits of lathe tool grinding automation?

Automation leads to faster production, lower costs, and higher quality products. It helps businesses grow and adapt to changes in the market.

Resources for Further Learning and Implementation

Recommended literature and online courses. Industry associations and forums for networking.There are plenty of ways to boost your skills in lathe tool grinding and metal lathe automation. Grab some great books to read and dive into online courses. They are like treasure chests of knowledge! Joining industry associations and forums is also helpful. You can meet others who share your interests. And who knows, you might even make a new friend or two! Here are some resources to check out:

| Resource Type | Resource Name |

|---|---|

| Book | Lathe Tool Basics |

| Online Course | Introduction to Lathe Automation |

| Association | International Machine Tool Association |

| Forum | Machinist World Discussions |

Conclusion

In summary, lathe tool grinding is vital for keeping your tools sharp. Metal lathe automation makes this process faster and more precise. By learning about these techniques, you can improve your projects. We encourage you to explore more about tool maintenance and automation. This knowledge will help you become a better maker in your metalworking journey!FAQs

Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Automation:Sure! Lathe tool grinding is when you sharpen tools that work with a machine called a lathe. A lathe helps us shape metal into different things. Metal lathe automation means using machines to do the work automatically. This makes it faster and helps us make things more accurately. With these tools and machines, we can create fun and useful items!

Sure! Please share the question you’d like me to answer.

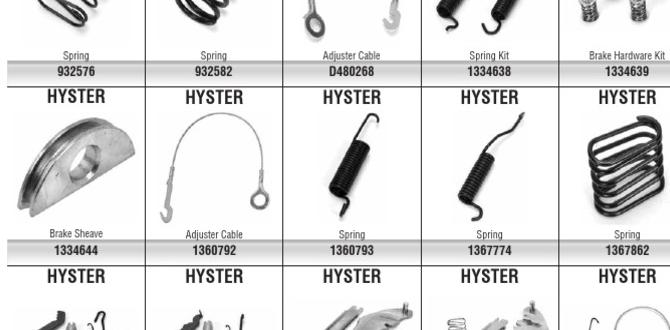

What Are The Key Factors To Consider When Selecting A Grinding Wheel For Lathe Tool Sharpening?When choosing a grinding wheel for sharpening lathe tools, you should think about a few important things. First, consider the type of metal you are sharpening. Different metals need different wheels. Next, look at the wheel’s hardness; a harder wheel lasts longer, but a softer wheel cuts faster. Finally, check the size of the wheel; it should fit your grinder perfectly. These factors help you sharpen tools better!

How Can Automation Improve The Efficiency And Accuracy Of The Lathe Tool Grinding Process?Automation can make lathe tool grinding faster and more precise. With machines doing the work, we can save time and reduce mistakes. These machines follow the same steps each time, so they keep making pieces that are the same. This means we get better quality tools without wasting materials. Overall, automation helps us work smarter and get great results!

What Are The Differences Between Cnc Grinding Machines And Traditional Manual Grinding Methods In Lathe Tool Production?CNC grinding machines use computers to control the grinding process. This makes them very precise and fast. In contrast, traditional manual grinding relies on a person’s skills, which can vary. With CNC machines, you get consistent results every time. Manual methods can take longer and may not be as accurate.

How Does The Tooling Geometry Impact The Performance And Lifespan Of Lathe Tools After Grinding?The shape of a lathe tool, called tooling geometry, affects how well it cuts. A good shape helps the tool stay sharp longer. If the angle is just right, it can slice through materials easily. When it’s not right, the tool wears out faster. So, choosing the right shape keeps your tools working well for more time!

What Advancements In Automation Technology Have Emerged In Recent Years To Enhance Lathe Tool Grinding Operations?In recent years, we have seen many cool tools for grinding lathe tools. Robots can now do the grinding work faster and more accurately. Machines are getting smarter, using sensors to check if everything is working right. New software helps plan the grinding tasks better. All these advancements make the grinding process easier and help us save time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe tool grinding is when you sharpen tools that work with a machine called a lathe. A lathe helps us shape metal into different things. Metal lathe automation means using machines to do the work automatically. This makes it faster and helps us make things more accurately. With these tools and machines, we can create fun and useful items!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Grinding Wheel For Lathe Tool Sharpening?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a grinding wheel for sharpening lathe tools, you should think about a few important things. First, consider the type of metal you are sharpening. Different metals need different wheels. Next, look at the wheel’s hardness; a harder wheel lasts longer, but a softer wheel cuts faster. Finally, check the size of the wheel; it should fit your grinder perfectly. These factors help you sharpen tools better!”}},{“@type”: “Question”,”name”: “How Can Automation Improve The Efficiency And Accuracy Of The Lathe Tool Grinding Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automation can make lathe tool grinding faster and more precise. With machines doing the work, we can save time and reduce mistakes. These machines follow the same steps each time, so they keep making pieces that are the same. This means we get better quality tools without wasting materials. Overall, automation helps us work smarter and get great results!”}},{“@type”: “Question”,”name”: “What Are The Differences Between Cnc Grinding Machines And Traditional Manual Grinding Methods In Lathe Tool Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC grinding machines use computers to control the grinding process. This makes them very precise and fast. In contrast, traditional manual grinding relies on a person’s skills, which can vary. With CNC machines, you get consistent results every time. Manual methods can take longer and may not be as accurate.”}},{“@type”: “Question”,”name”: “How Does The Tooling Geometry Impact The Performance And Lifespan Of Lathe Tools After Grinding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of a lathe tool, called tooling geometry, affects how well it cuts. A good shape helps the tool stay sharp longer. If the angle is just right, it can slice through materials easily. When it’s not right, the tool wears out faster. So, choosing the right shape keeps your tools working well for more time!”}},{“@type”: “Question”,”name”: “What Advancements In Automation Technology Have Emerged In Recent Years To Enhance Lathe Tool Grinding Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In recent years, we have seen many cool tools for grinding lathe tools. Robots can now do the grinding work faster and more accurately. Machines are getting smarter, using sensors to check if everything is working right. New software helps plan the grinding tasks better. All these advancements make the grinding process easier and help us save time!”}}]}