Have you ever watched a metal lathe at work? It’s fascinating! A lathe spins metal while tools shape it into smooth parts. But how does the tool stay sharp? That’s where lathe tool grinding comes in. It ensures tools are precise and ready for action.

Imagine building something cool with your own hands. It could be a toy, a gift, or a simple tool. But without the right equipment, how would you get started? The metal lathe drive system is key. It powers the lathe, turning raw metal into amazing creations.

Did you know that skilled workers often grind their tools to improve their work? This process not only makes tools effective but also helps create better products. Learning about lathe tool grinding and drive systems can open a world of possibilities! Get ready to dive into the world of metalworking!

Lathe Tool Grinding: Improving Metal Lathe Drive System Efficiency

Understanding Lathe Tool Grinding and Drive Systems

Lathe tool grinding is essential for creating precise metal parts. Properly shaped tools cut better and last longer. A metal lathe drive system powers the lathe, spinning the workpiece efficiently. Did you know that the right drive system can improve tool performance significantly? This means smoother finishes and faster jobs. Learning how to grind lathe tools contributes to better craftsmanship and helps you work smarter, not harder. Ready to enhance your lathe skills?What is a Metal Lathe Drive System?

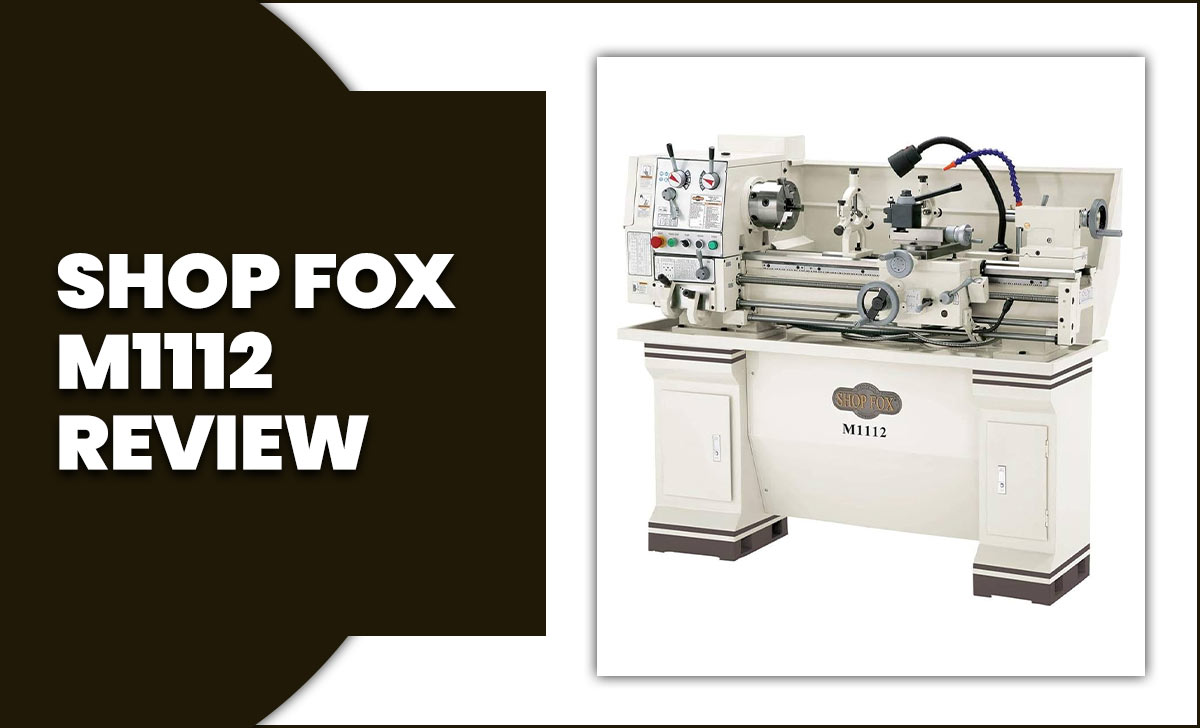

Definition and purpose of a metal lathe drive system. Different types of drive systems used in metal lathes.A metal lathe drive system is the heart of the machine. It helps to turn metal pieces smoothly. Think of it as the engine of a car. With different drive types, each has its own charm! Some use belts, while others stick to gears. Every system has a special job, making sure your lathe works like a well-oiled machine. Here’s a quick table that shows some drive system types:

| Drive System Type | Description |

|---|---|

| Belt Drive | Uses belts to transmit power; it’s quiet and simple! |

| Gear Drive | Utilizes gears for more power; think of it as the muscle of lathes! |

| Direct Drive | Connects the motor directly; it’s fast but might need some gentleness! |

Understanding these systems helps you pick the right lathe for your needs. Remember, a happy lathe equals happy metal turning!

Benefits of Proper Lathe Tool Grinding

Enhanced precision and accuracy in machining. Extended lifespan of tools and machinery.Grinding lathe tools properly brings many benefits to the table. First, it improves precision and accuracy in machining. This means fewer mistakes and a smoother project. Next, it extends the lifespan of tools and machinery. Imagine your lathe tools lasting twice as long! They will be drinking their coffee while working hard. Proper grinding saves money and effort in the long run. So, let’s keep our tools sharp and happy!

| Benefit | Description |

|---|---|

| Precision | Offers more accurate cuts |

| Longevity | Increases tool and machine lifespan |

Common Lathe Tool Grinding Techniques

Comparison of different grinding techniques (e.g., Continuous vs. Oscillating). Pros and cons of each technique in practical application.Grinding tools can be tricky, but understanding different techniques helps. Continuous grinding is like a smooth dance—steady and consistent. It’s great for precision but can heat things up, which might cause a meltdown (not the fun kind!). On the other hand, oscillating grinding is a bit bouncy! It reduces heat but might not be as exact. Let’s weigh the pros and cons in handy style:

| Grinding Technique | Pros | Cons |

|---|---|---|

| Continuous | Precise cuts, smooth finish | Can overheat, tougher learning curve |

| Oscillating | Less heat build-up, easy to learn | Less precise, may require more effort |

Choose wisely, and your metal will thank you, or at least not cry in pain!

Maintenance of Lathe Tool Grinding Equipment

Routine maintenance tips for optimal performance. Troubleshooting common problems in grinding systems.Keeping lathe tool grinding equipment in good shape is important for smooth operations. Regular checks can prevent problems. Here are some tips:

- Clean the machine after each use.

- Check for worn parts monthly.

- Lubricate moving parts regularly.

- Sharpen tools to keep them effective.

If you encounter issues, try these troubleshooting steps:

- If the machine vibrates, check for loose parts.

- If grinding is uneven, inspect the tool angle.

- For strange noises, ensure all components are tight.

What are some routine maintenance practices for lathe tool grinding equipment?

Routine tasks include checking for wear and tear, cleaning parts, and keeping everything lubricated. These actions help avoid more serious problems later.

How can common problems in grinding systems be fixed?

To fix problems, start with checking for loose parts or cleaning the work area. A little attention goes a long way!

Choosing the Right Grinding Tools and Accessories

Factors to consider when selecting grinding tools. Recommended tools and accessories for different applications.Picking the right grinding tools is important for your project. There are a few factors to consider. Think about material type, tool size, and grit level needed. The right accessory can make your job easier and safer.

- For fine details, use small grinding wheels.

- For rough cuts, go for larger, tougher wheels.

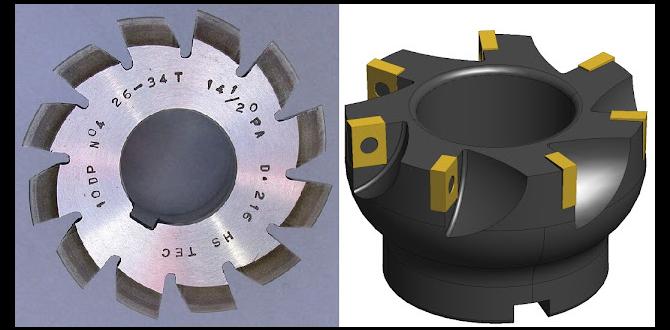

- For metals, use high-speed steel or carbide tools.

Choosing wisely helps you work better and achieve great results!

What factors should you consider when selecting grinding tools?

Consider the material you’ll grind and how fine you want the finish. Also, think about the size of the tool and how comfortable it is to handle. Good tools make your work easier!

Which tools and accessories are recommended for different applications?

Great Tools for Different Jobs

- For metal: High-speed steel tools.

- For wood: Soft grinding wheels.

- For polishing: Polishing pads and compounds.

Using the right tools can help you get the best results in less time!

Safety Considerations in Lathe Tool Grinding

Key safety practices to follow. Common hazards and how to mitigate them.Grinding tools on a lathe can be fun, but safety is no joke! Always wear protective gear like goggles and gloves. Keep long hair tied back—nobody wants a surprise visit from a spinning chuck! Common hazards include flying debris and loud noises. To stay safe, use guards and ensure your workspace is tidy. Remember, a clean area is a happy area!

| Hazard | Solution |

|---|---|

| Flying debris | Wear safety goggles |

| Loud noise | Use ear protection |

| Loose clothing | Tie back long hair |

By following these key practices, you can turn your grinding sessions into safe adventures!

Future Trends in Lathe Tool Grinding Technology

Innovations in lathe tool grinding systems. Impact of automation and robotics in the grinding process.New ideas are changing how we grind lathe tools. Advanced grinding systems are being developed for better results. Automation is making the process faster and more accurate. Robots can now handle tasks that need precision and care.

- Quieter machines with less vibration improve performance.

- Smart technology helps to monitor and adjust the grinding process.

- Robots can work 24/7, increasing productivity.

These trends show that the future of lathe tool grinding is bright. As technology grows, so does the ability to create better tools.

What are the benefits of automation in lathe tool grinding?

Automation helps increase speed and accuracy. It reduces human error and allows workers to focus on important tasks.

Comparative Analysis: Manual vs. CNC Lathe Tool Grinding Systems

Differences in functionality and efficiency. Situations best suited for each system.When comparing manual and CNC lathe tool grinding systems, their differences are as clear as day! Manual systems need skilled hands and lots of practice. They can create unique shapes but take time and patience. CNC systems, on the other hand, are like robots on wheels. They work fast and can make precise cuts without coffee breaks. They shine in situations where speed and accuracy are key, while manuals are great for craft and detail.

| Feature | Manual Lathe | CNC Lathe |

|---|---|---|

| Functionality | High skill required | Automatic and precise |

| Efficiency | Slower, more hands-on | Fast and efficient |

| Best Use | Crafting unique designs | Mass production |

So, choosing between them depends on your needs. Need speed? Go CNC! Want to sculpt a masterpiece? Grab that manual lathe and get grinding! Remember, each has its quirks, like a cat and dog. Both can be awesome in their own way!

Frequently Asked Questions about Lathe Tool Grinding

Common inquiries and expert answers. Addressing misconceptions around lathe drive systems and grinding tools.Many people have questions about lathe tool grinding. Understanding this topic helps avoid confusion. Here are some common questions and their answers:

What is the best way to grind lathe tools?

The best way to grind lathe tools is to use a reliable sharpening setup with a proper angle. A consistent angle produces sharper tools.

Do I need special tools for lathe grinding?

You need specific tools like a bench grinder and a tool rest to grind effectively. These tools help maintain accuracy.

How do I care for my grinding tools?

- Keep them clean. Regularly remove dust and debris.

- Store them properly. Use a safe place to avoid damage.

- Check for wear. Replace tools that are too worn down.

Remember, a well-maintained grinding setup leads to better results with lathe tools. Don’t hesitate to reach out with more questions!

Conclusion

In conclusion, understanding lathe tool grinding and the metal lathe drive system is key for anyone working with lathes. You can create precise parts by using sharp tools and a reliable drive system. If you want to improve your skills, consider practicing grinding your own tools. For more information, check out additional resources or tutorials online. Enjoy your machining journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Drive Systems:Sure! When you grind a lathe tool, you make it sharp so it can cut metal better. A metal lathe is a machine that spins metal to help shape it. The drive system helps the lathe move, so you can work on the metal smoothly. You can use different speeds to cut the metal just right. Make sure to be careful and wear safety gear while using the lathe!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Steps Involved In Properly Grinding A Cutting Tool For A Metal Lathe?To grind a cutting tool for a metal lathe, you first need to choose the right tool. Next, you set the tool on a grinding machine. Then, slowly move the tool against the grinder’s wheel. You want to make sure the end is sharp and has the right shape. Finally, check it carefully to see if it’s ready to use.

How Do Different Materials Of Lathe Tools Affect The Grinding Process And Cutting Performance?Different materials for lathe tools change how they cut and how easy they are to sharpen. For example, steel tools are easier to grind but wear out faster. Harder materials, like carbide, stay sharp longer, but they can be tricky to grind. When you choose a material, think about how you want it to cut and how much time you want to spend sharpening it.

What Are The Common Types Of Drive Systems Used In Metal Lathes, And How Do They Influence Machining Efficiency?Metal lathes use different drive systems, like belt drives and direct drives. Belt drives use belts to connect the motor to the lathe. They are good for changing speeds but might slip sometimes. Direct drives connect the motor straight to the lathe, offering more power and stability. Both types help us make smooth and accurate cuts, making our work faster and better.

How Can Improper Tool Grinding Impact The Performance And Lifespan Of A Metal Lathe?Improper tool grinding can make cutting tools dull. When tools aren’t sharp, they can work slowly and make messy cuts. This can damage our metal lathe, which is the machine we use for shaping metal. If our tools are bad, we will have to replace them more often. This means we spend more time and money, and our lathe won’t last as long.

What Safety Precautions Should Be Taken During The Lathe Tool Grinding Process To Ensure Operator Safety?When grinding tools on a lathe, you should wear safety glasses to protect your eyes. Make sure your hair is tied back and your clothes are snug so they don’t get caught. Always keep your hands away from the spinning parts. Don’t forget to keep the area clean and dry to avoid slips and falls. Finally, listen carefully to any safety rules from your teacher or supervisor.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Drive Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you grind a lathe tool, you make it sharp so it can cut metal better. A metal lathe is a machine that spins metal to help shape it. The drive system helps the lathe move, so you can work on the metal smoothly. You can use different speeds to cut the metal just right. Make sure to be careful and wear safety gear while using the lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Steps Involved In Properly Grinding A Cutting Tool For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To grind a cutting tool for a metal lathe, you first need to choose the right tool. Next, you set the tool on a grinding machine. Then, slowly move the tool against the grinder’s wheel. You want to make sure the end is sharp and has the right shape. Finally, check it carefully to see if it’s ready to use.”}},{“@type”: “Question”,”name”: “How Do Different Materials Of Lathe Tools Affect The Grinding Process And Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials for lathe tools change how they cut and how easy they are to sharpen. For example, steel tools are easier to grind but wear out faster. Harder materials, like carbide, stay sharp longer, but they can be tricky to grind. When you choose a material, think about how you want it to cut and how much time you want to spend sharpening it.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Drive Systems Used In Metal Lathes, And How Do They Influence Machining Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different drive systems, like belt drives and direct drives. Belt drives use belts to connect the motor to the lathe. They are good for changing speeds but might slip sometimes. Direct drives connect the motor straight to the lathe, offering more power and stability. Both types help us make smooth and accurate cuts, making our work faster and better.”}},{“@type”: “Question”,”name”: “How Can Improper Tool Grinding Impact The Performance And Lifespan Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper tool grinding can make cutting tools dull. When tools aren’t sharp, they can work slowly and make messy cuts. This can damage our metal lathe, which is the machine we use for shaping metal. If our tools are bad, we will have to replace them more often. This means we spend more time and money, and our lathe won’t last as long.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Lathe Tool Grinding Process To Ensure Operator Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When grinding tools on a lathe, you should wear safety glasses to protect your eyes. Make sure your hair is tied back and your clothes are snug so they don’t get caught. Always keep your hands away from the spinning parts. Don’t forget to keep the area clean and dry to avoid slips and falls. Finally, listen carefully to any safety rules from your teacher or supervisor.”}}]}