Imagine you’re in a workshop filled with cool machines and tools. You spot a shiny lathe spinning round and round. It’s an amazing tool that shapes metal into all sorts of neat creations. Have you ever wondered how it gets its perfect edges? That’s where lathe tool grinding comes in.

Lathe tool grinding is an important skill. It helps make sure tools work well and last long. With the right grinding, a lathe can produce smooth surfaces on your metal projects. But that’s not all! The lathe pulley also plays a key role. It helps the lathe move smoothly and easily when you’re working.

Did you know that learning how to grind lathe tools can be fun? You can start with simple shapes. As you learn, you can create more complex designs! This process not only sharpens your tools but also your skills. So, get ready to discover the fascinating world of lathe tool grinding and how it connects to metal lathe pulleys.

Lathe Tool Grinding: Metal Lathe Pulley Techniques Explained

Lathe Tool Grinding: Metal Lathe Pulley

Lathe tool grinding helps shape and sharpen tools used in metalworking. Using a lathe, you can create precise shapes easily. Have you ever seen a metal pulley’s smooth surface? That’s thanks to proper grinding techniques. By learning the right methods, you increase the lifespan of your tools and improve your projects’ quality. Understanding the importance of lathe tool grinding is key for anyone working with metal. It’s like having a secret weapon in your workshop!Types of Lathe Tools

Explanation of various lathe tools used in metalworking. Characteristics and applications of each tool type.Lathe tools come in different shapes and sizes. Each type serves a special job in metalworking. Here are a few common kinds:

- Turning Tools: Used for shaping the metal. They create smooth surfaces.

- Boring Bars: Ideal for making holes bigger. They ensure precision.

- Parting Tools: Great for cutting off pieces. They work fast and efficiently.

- Knurling Tools: Used to add patterns. They create grip on metal surfaces.

Each tool helps metalworkers create amazing things. Knowing these tools makes work easier!

What are the main types of lathe tools?

The main types include turning tools, boring bars, parting tools, and knurling tools. Each type has its purpose, making it key for metalworking tasks.

The Role of Pulley Systems in Metal Lathes

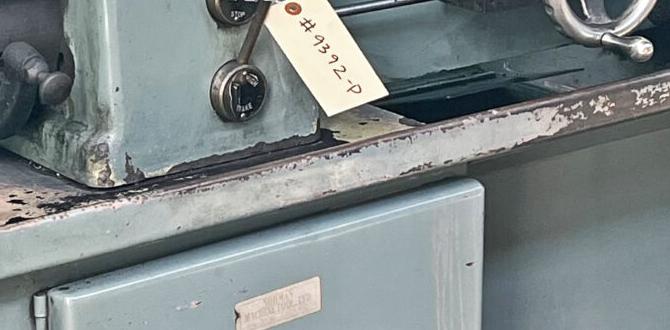

Description of metal lathe pulley systems and their functions. Importance of proper pulley maintenance for tool effectiveness.In metal lathes, pulley systems play an important part. They connect the motor to the lathe, helping to rotate the cutting tools. This means tools can spin at different speeds for better precision. Good pulley maintenance is key for overall tool effectiveness. If pulleys are not cared for, they can wear out or malfunction. Regular checks keep everything running smoothly.

Why is pulley maintenance important?

Proper pulley maintenance ensures that tools work effectively and last longer.

- Reduces wear and tear on parts.

- Helps maintain correct speeds.

- Enhances safety during operation.

Remember, a well-maintained system leads to better performance and results!

Grinding Techniques for Optimal Tool Performance

Detailed analysis of standard grinding methods. Best practices for achieving sharp, precise edges.There are several effective grinding techniques to make your tools shine like new. First, standard grinding methods include using a bench grinder or a belt sander. These tools help shape metal quickly. To achieve sharp and precise edges, keep a steady hand and a focused eye. Remember, practice makes perfect, much like riding a bike but hopefully with fewer scraped knees!

| Grinding Method | Best For |

|---|---|

| Bench Grinder | Quick shaping and sharpening |

| Belt Sander | Fine finishing |

| Hand Files | Detail work |

Following the right techniques can boost your tool’s performance and keep those edges razor-sharp. So, grab your gear and get grinding! Who knew metal could be so much fun?

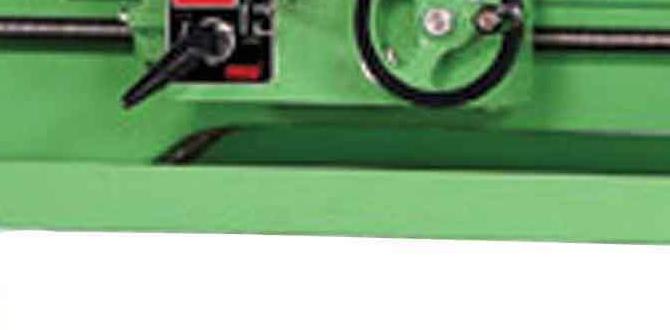

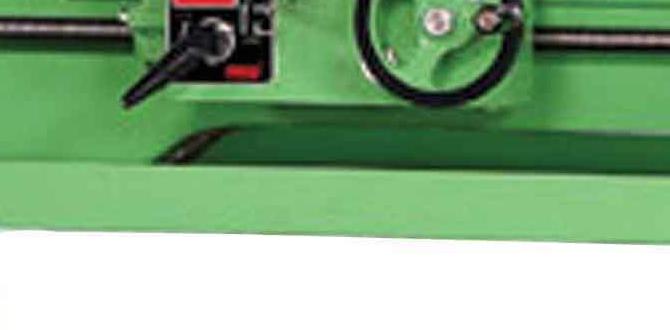

Selecting the Right Grinding Equipment

Comparison of grinding machines and their suitability for lathe tools. Features to look for in a grinding machine for optimal results.Choosing the right grinding machine is key for lathe tools. Different machines have unique features. Some are better for shaping metal, while others focus on sharpening. Here are things to look for:

- Speed Control: Adjusting speed helps in precise grinding.

- Wheel Size: Larger wheels can grind faster but may require more space.

- Stability: A stable machine reduces vibrations for smoother results.

Pick a machine that suits your needs for the best performance.

What makes a grinding machine suitable for lathe tools?

A suitable grinding machine can enhance tool life and performance. The right features can lead to better precision and faster results.

Safety Measures in Lathe Tool Grinding

Essential safety gear and precautions. Standard operating procedures to ensure workplace safety.Grinding lathe tools can be dangerous if caution isn’t taken. Wearing the correct safety gear is a must. Always use:

- Safety glasses to protect your eyes.

- Ear protection to keep your hearing safe.

- Gloves for hand safety, but ensure they’re snug.

- Steel-toed boots to shield your feet from heavy items.

Following standard operating procedures keeps everyone safe. Here are some key steps:

- Keep your work area clean and organized.

- Always check your tools before use.

- Never leave the machine running unattended.

By following these guidelines, you can work safely and effectively.

What are essential safety measures when grinding lathe tools?

The most important safety measures include wearing safety glasses, ear protection, and gloves, while keeping your workspace clean and following all procedures.

Maintenance of Lathe Tools and Grinding Equipment

Routine maintenance practices for lathe tools. Importance of keeping grinding equipment in top condition.Taking good care of lathe tools and grinding equipment is very important. Regular checks can help keep everything running smoothly. Here are some simple ways to maintain your tools:

- Clean tools after each use.

- Check for any wear or damage.

- Sharpen blades as needed.

- Lubricate moving parts regularly.

By keeping grinding equipment in top condition, you ensure better performance. This can save time and materials. Always remember, a well-maintained tool works more efficiently, which helps produce high-quality work.

Why is maintaining lathe tools important?

Maintaining lathe tools is essential to ensure their effectiveness and longevity. Well-kept tools help avoid problems that can slow down work. Regular attention also promotes safety in the workshop.

Industry Trends in Lathe Tool Grinding

Emerging technologies and their implications for grinding techniques. Future perspectives on automation and efficiency in lathe tool grinding.New tools and methods are changing lathe tool grinding. Technologies like automation and robotics make processes faster and more precise. This helps workers produce better tools. With rising demands, companies focus on efficiency. They are finding ways to save time and reduce waste. The future looks bright for this field. Keeping up with these trends will be important for success.

What are the emerging technologies in lathe tool grinding?

Emerging technologies include automation and advanced grinding machines, which improve precision and speed.

Key trends include:

- Increased use of robotics for higher efficiency

- Smart grinding machines that adapt to tasks

- Data analysis for better performance tracking

Resources for Further Learning

Recommended books, online courses, and workshops. Key organizations and forums for metalworking professionals.Want to dive deeper into the world of metalworking? You’re in luck! There are plenty of resources to boost your skills. Check out some recommended books that are full of tips. There are also online courses that make learning fun—like a party, but with tools instead of cake! Don’t forget about workshops; they’re a hands-on way to learn with experts. Join forums and organizations like the American Society of Mechanical Engineers. They chat about everything, from lathe tool grinding to pulley secrets!

| Resource Type | Examples |

|---|---|

| Books | “The Complete Guide to Metalworking” |

| Online Courses | Coursera, Udemy |

| Workshops | Local Technical Colleges |

| Organizations | American Society of Mechanical Engineers |

| Forums | Metalworking.com, Reddit |

Conclusion

In summary, lathe tool grinding is important for shaping metal effectively. The metal lathe pulley helps keep the machine running smoothly. By learning these skills, you can create precise parts and improve your projects. Explore more about lathe tools to enhance your knowledge. You’ll enjoy hands-on experience and gain confidence in metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Pulleys:Sure! Here are some answers about lathe tool grinding and metal lathe pulleys. 1. **What is lathe tool grinding?** Lathe tool grinding is when you sharpen tools used on a lathe machine. It helps the tools cut better. 2. **Why do we need sharp tools?** Sharp tools help us make cleaner and smoother cuts on the metal. This makes our work look nice and neat. 3. **What are metal lathe pulleys?** Metal lathe pulleys are round parts that help turn the lathe. They work like wheels to move things along. 4. **How do pulleys affect the lathe?** Pulleys help control the speed of the lathe. This means we can work faster or slower, depending on what we need. 5. **Can I grind my tools at home?** Yes! You can grind your tools at home with the right equipment and safety gear. Always be careful when using tools!

Sure! Please provide the question you would like me to answer.

What Are The Different Types Of Lathe Tools That Can Be Effectively Sharpened Using Tool Grinding Techniques?You can sharpen different types of lathe tools. Some of these tools include turning tools, parting tools, and boring tools. Turning tools shape the wood or metal as it spins. Parting tools cut the material to make smaller pieces. Boring tools create holes in the material. Each of these tools needs sharpening to stay effective.

How Does The Shape And Angle Of A Lathe Tool Impact Its Performance When Machining Different Types Of Metals?The shape and angle of a lathe tool change how well it cuts metal. A sharp angle can help the tool slice through soft metals easily. However, for hard metals, a different shape with a wider angle can work better. This helps keep the tool from breaking. So, we need to choose the right tool shape for the metal we are working with.

What Materials Are Commonly Used For Making Pulleys In Metal Lathe Operations, And How Do They Influence Pulley Design?In metal lathe operations, pulleys are often made from materials like aluminum, steel, or plastic. Aluminum is light and strong, so it helps pulleys spin fast. Steel is very tough and can handle heavy loads, but it is heavier. Plastic is easy to shape but may not be as strong as metal. The choice of material affects how the pulley works and how long it lasts.

What Are The Essential Steps In The Grinding Process For Achieving A Precise Cutting Edge On Lathe Tools?To get a sharp cutting edge on lathe tools, you follow a few simple steps. First, you pick the right tool and check its shape. Next, you set the tool at the right angle on the grinding machine. Then, you carefully move the tool against the grinding wheel until it’s sharp. Finally, you clean the tool and check the edge to make sure it’s smooth.

How Can Improper Sharpening Of Lathe Tools Affect Both The Quality Of The Machined Surface And The Lifespan Of The Tools?If you sharpen lathe tools the wrong way, they won’t cut well. This can make the surface of the metal look rough and messy. It also makes the tools wear out faster. Using dull tools means you have to replace them sooner, which costs more money. So, it’s important to sharpen tools correctly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about lathe tool grinding and metal lathe pulleys. 1. **What is lathe tool grinding?** Lathe tool grinding is when you sharpen tools used on a lathe machine. It helps the tools cut better. 2. **Why do we need sharp tools?** Sharp tools help us make cleaner and smoother cuts on the metal. This makes our work look nice and neat. 3. **What are metal lathe pulleys?** Metal lathe pulleys are round parts that help turn the lathe. They work like wheels to move things along. 4. **How do pulleys affect the lathe?** Pulleys help control the speed of the lathe. This means we can work faster or slower, depending on what we need. 5. **Can I grind my tools at home?** Yes! You can grind your tools at home with the right equipment and safety gear. Always be careful when using tools!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Lathe Tools That Can Be Effectively Sharpened Using Tool Grinding Techniques?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can sharpen different types of lathe tools. Some of these tools include turning tools, parting tools, and boring tools. Turning tools shape the wood or metal as it spins. Parting tools cut the material to make smaller pieces. Boring tools create holes in the material. Each of these tools needs sharpening to stay effective.”}},{“@type”: “Question”,”name”: “How Does The Shape And Angle Of A Lathe Tool Impact Its Performance When Machining Different Types Of Metals?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape and angle of a lathe tool change how well it cuts metal. A sharp angle can help the tool slice through soft metals easily. However, for hard metals, a different shape with a wider angle can work better. This helps keep the tool from breaking. So, we need to choose the right tool shape for the metal we are working with.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Making Pulleys In Metal Lathe Operations, And How Do They Influence Pulley Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe operations, pulleys are often made from materials like aluminum, steel, or plastic. Aluminum is light and strong, so it helps pulleys spin fast. Steel is very tough and can handle heavy loads, but it is heavier. Plastic is easy to shape but may not be as strong as metal. The choice of material affects how the pulley works and how long it lasts.”}},{“@type”: “Question”,”name”: “What Are The Essential Steps In The Grinding Process For Achieving A Precise Cutting Edge On Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a sharp cutting edge on lathe tools, you follow a few simple steps. First, you pick the right tool and check its shape. Next, you set the tool at the right angle on the grinding machine. Then, you carefully move the tool against the grinding wheel until it’s sharp. Finally, you clean the tool and check the edge to make sure it’s smooth.”}},{“@type”: “Question”,”name”: “How Can Improper Sharpening Of Lathe Tools Affect Both The Quality Of The Machined Surface And The Lifespan Of The Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you sharpen lathe tools the wrong way, they won’t cut well. This can make the surface of the metal look rough and messy. It also makes the tools wear out faster. Using dull tools means you have to replace them sooner, which costs more money. So, it’s important to sharpen tools correctly!”}}]}