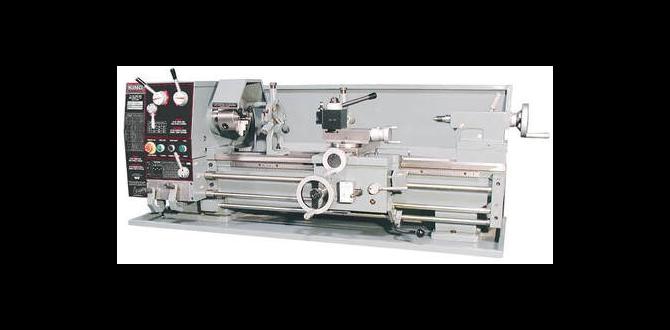

Have you ever wondered how metal parts are made with such precision? One important tool in this process is the lathe. It spins the metal while sharp tools shape it into the right form. But what happens if those tools aren’t sharp enough? They can ruin your work!

That’s where lathe tool grinding comes in. It helps keep those tools sharp and effective. And when you use a quick change tool post, the process becomes even easier. Picture this: no more wasting time switching tools or struggling with setups. You can focus on making your project shine.

Did you know that many professional engineers and hobbyists use these tools to make everything from tiny parts to large machinery? With the right tools and techniques, they can create amazing things. Are you ready to learn how to make metal lathe work for you? Let’s dive in!

Lathe Tool Grinding: Metal Lathe Quick Change Tool Post Guide

Lathe Tool Grinding: Quick Change Tool Post

A lathe tool grinding metal lathe with a quick change tool post makes work easier and faster. Have you ever used a tool that just can’t keep up? With this setup, swapping tools is a breeze. You save time and effort, helping you finish projects quicker. This tool post increases accuracy and efficiency. Plus, it’s great for beginners as it improves their skills. Wouldn’t you enjoy smoother cuts and better finishes in your work?Understanding Lathe Tool Grinding

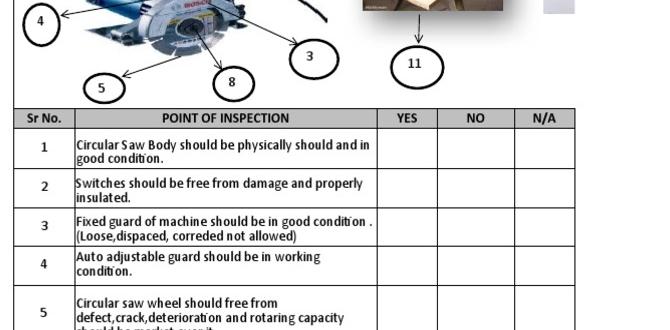

Definition and importance of lathe tool grinding. Types of grinding methods used in metal lathes.Lathe tool grinding is the process of sharpening and shaping tools used in metal lathes. It is crucial because well-ground tools help create smooth and precise parts. Different methods are used for grinding, including:

- Bench Grinding: Uses a rotating wheel to sharpen tools by hand.

- Surface Grinding: Produces flat surfaces on tools.

- Cylindrical Grinding: Shapes the outer surface of cylindrical objects.

- Tool and Cutter Grinding: Focuses on sharpening cutting tools.

Understanding these methods helps in getting better results from your lathe.

Why is lathe tool grinding important?

Effective lathe tool grinding ensures tools work correctly and last longer. This saves time and money on repairs and replacements. Sharp tools also produce better quality work, making the entire process easier and faster.

Step-by-Step Guide to Grinding Lathe Tools

Detailed process of grinding different lathe tools. Common mistakes to avoid during the grinding process.Grinding lathe tools can feel like art. Start by selecting the right tool, then set the angle for grinding. Use a slow, steady motion. Watch your fingers! The last thing you want is a funny story about how you lost a pinky. Common mistakes include grinding too fast or using a dull wheel. Both can ruin your tools and your day. Here’s a quick reference to keep you on track:

| Tool Type | Angle for Grinding | Common Mistake |

|---|---|---|

| Cutting Tool | 60° – 80° | Not keeping the right angle |

| Parting Tool | 30° – 50° | Grinding too much too quickly |

By following these steps, your tools will stay sharp, and you’ll be a machining superstar!

Benefits of Using a Quick Change Tool Post

Advantages of quick change tool posts over traditional tool holders. Impact on productivity and efficiency in machining operations.Switching tools on a lathe can be like a game of musical chairs—fun at first, but frustrating if it takes too long! A quick change tool post lets you swap tools in a flash, saving time and keeping productivity high. With this nifty gadget, machinists can change tools in under a minute. That means more cutting and less waiting! Plus, no more juggling heavy tool holders that need a workout to switch. Lighter tools mean happier workers!

| Feature | Quick Change Tool Post | Traditional Tool Holder |

|---|---|---|

| Time to Change Tools | Under 1 minute | Several minutes |

| Worker Comfort | Light and easy | Heavy and clunky |

| Productivity Boost | Significant | Low |

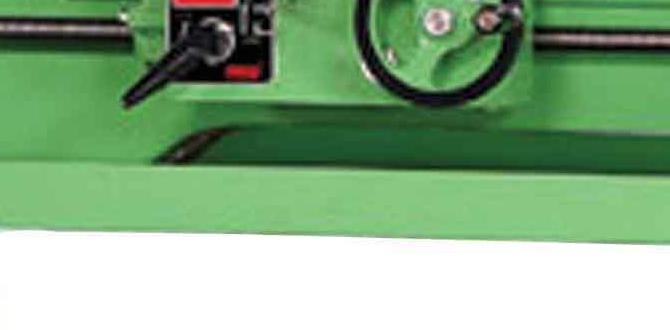

How to Install a Quick Change Tool Post

Required tools and materials for installation. Stepbystep installation process for beginners.To install a quick change tool post, you will need a few simple tools and materials. Gather a wrench, screwdriver, and a set of Allen keys. Also, have the tool post and its mounting plate ready.

Follow these easy steps for installation:

- Remove the existing tool holder from your lathe.

- Clean the mounting surface for a good fit.

- Position the quick change tool post on the base.

- Secure it with screws provided.

- Tighten everything with your tools.

That’s it! You are now ready to change tools quickly and easily.

What tools do I need to install a quick change tool post?

You will need a wrench, screwdriver, and Allen keys to install a quick change tool post. Make sure to prepare these tools before starting.

Maintenance Tips for Lathe Tools and Tool Posts

Best practices for maintaining tools for longevity. Troubleshooting common issues with quick change tool posts.Keeping your lathe tools and tool posts in good shape is very important. Here are some best practices:

- Clean tools after every use.

- Oil moving parts to reduce wear.

- Store tools in a dry place.

- Check for damage before using.

If you notice problems with quick change tool posts, follow these tips:

- Ensure all screws are tight.

- Lubricate sliding surfaces.

- Replace worn-out parts quickly.

These steps can help your tools last longer and work better!

How can I troubleshoot issues with quick change tool posts?

To fix common problems, check the tool holder and screws. Tighten or replace them if needed. Always keep the surfaces clean and oiled for smooth operation.Comparative Analysis of Popular Quick Change Tool Posts

Review of leading brands and models in the market. Key features to consider when selecting a tool post.Choosing the right quick change tool post can feel like finding a needle in a haystack. With so many brands, it’s easy to get lost! Popular names include brands like Aloris, Phase II, and Dickson. Each offers unique features like easy setup and secure locking. Remember to look for durability, compatibility, and quick adjustments. A handy tip? A tool post that fits like your favorite pair of socks is usually a solid choice—no funky wiggle! Now, let’s break down some top models:

| Brand | Model | Key Features |

|---|---|---|

| Aloris | AXA | Heavy-duty, easy change |

| Phase II | 200-001 | Affordable, solid construction |

| Dickson | SC-4 | Reliable, quick setup |

Make your choice wisely, and your lathe will thank you later!

Real-World Applications of Lathe Tool Grinding and Quick Change Tool Posts

Case studies demonstrating effectiveness in various industries. Testimonials from professionals using grinding techniques and tool posts.Many industries use lathe tool grinding and quick change tool posts, turning them into unsung heroes of manufacturing! For example, a company making car parts saw a 30% increase in efficiency after switching to quick change tool posts. Professionals love them too. One machinist said, “These tools save so much time, I might just take up juggling!” Below is a table showing the effectiveness across different sectors:

| Industry | Efficiency Increase | Professional Feedback |

|---|---|---|

| Automotive | 30% | “Time-saver!” |

| Aerospace | 25% | “Game changer!” |

| Medical Devices | 20% | “Makes precision easy!” |

From faster production to precise cuts, these tools help businesses thrive while keeping spirits high. Who doesn’t want to work smarter, not harder?

Conclusion

In conclusion, using a lathe tool grinding metal lathe with a quick change tool post makes your work easier and faster. You can switch between tools quickly, saving time and effort. Understanding these tools helps you create better projects. We encourage you to explore more about lathe operations and practice your skills. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Quick Change Tool Posts:Lathe tool grinding is when we sharpen tools that fit into a lathe. A lathe is a machine that makes things like wood or metal round and smooth. Quick change tool posts help us switch tools easily without wasting time. This makes our work faster and more fun! Remember, keeping tools sharp is important for a good job!

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Fundamental Principles Of Sharpening Lathe Tools, And What Equipment Is Necessary For Effective Tool Grinding?To sharpen lathe tools, you need to keep the edges sharp and make them smooth. First, you should hold the tool at the right angle while grinding. This helps cut better when you use it. For effective tool grinding, you will need a bench grinder, sharpening stones, and a tool rest. These tools help you sharpen and keep your lathe tools working well.

How Does A Quick Change Tool Post Enhance The Efficiency And Precision Of Operations On A Metal Lathe?A quick change tool post helps us switch tools on a metal lathe easily and fast. This means we can work on different parts without wasting time. It also keeps the tools in the right place, which helps us make better cuts. With this tool post, we get more done in less time and with more accuracy.

What Are The Common Types Of Lathe Tools That Require Grinding, And How Do Their Sharpening Angles Differ?Common types of lathe tools that need grinding are cutting tools, chisels, and boring tools. Each type has a different angle for sharpening. For example, you sharpen a chisel at about 25 degrees. Boring tools need a sharper angle, usually around 30 degrees. These angles help the tools cut better when we use them.

What Factors Should Be Considered When Selecting A Quick Change Tool Post For A Specific Metal Lathe Model?When choosing a quick change tool post for your metal lathe, think about the lathe’s size and power. You need a tool post that fits well and can handle the work you plan to do. Check how easy it is to attach and remove tools. Also, look for one that lasts a long time and is made from good materials. Finally, make sure it’s safe and easy for you to use.

How Can Improper Tool Grinding Impact The Performance Of A Lathe And The Quality Of The Finished Workpiece?If you grind tools the wrong way, they won’t cut well. This can make the lathe, a machine we use to shape things, work poorly. You might end up with rough or uneven pieces instead of smooth ones. The finished workpiece might not fit properly or look nice. So, proper tool grinding is very important!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Quick Change Tool Posts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe tool grinding is when we sharpen tools that fit into a lathe. A lathe is a machine that makes things like wood or metal round and smooth. Quick change tool posts help us switch tools easily without wasting time. This makes our work faster and more fun! Remember, keeping tools sharp is important for a good job!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Fundamental Principles Of Sharpening Lathe Tools, And What Equipment Is Necessary For Effective Tool Grinding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To sharpen lathe tools, you need to keep the edges sharp and make them smooth. First, you should hold the tool at the right angle while grinding. This helps cut better when you use it. For effective tool grinding, you will need a bench grinder, sharpening stones, and a tool rest. These tools help you sharpen and keep your lathe tools working well.”}},{“@type”: “Question”,”name”: “How Does A Quick Change Tool Post Enhance The Efficiency And Precision Of Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick change tool post helps us switch tools on a metal lathe easily and fast. This means we can work on different parts without wasting time. It also keeps the tools in the right place, which helps us make better cuts. With this tool post, we get more done in less time and with more accuracy.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Lathe Tools That Require Grinding, And How Do Their Sharpening Angles Differ?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of lathe tools that need grinding are cutting tools, chisels, and boring tools. Each type has a different angle for sharpening. For example, you sharpen a chisel at about 25 degrees. Boring tools need a sharper angle, usually around 30 degrees. These angles help the tools cut better when we use them.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Quick Change Tool Post For A Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a quick change tool post for your metal lathe, think about the lathe’s size and power. You need a tool post that fits well and can handle the work you plan to do. Check how easy it is to attach and remove tools. Also, look for one that lasts a long time and is made from good materials. Finally, make sure it’s safe and easy for you to use.”}},{“@type”: “Question”,”name”: “How Can Improper Tool Grinding Impact The Performance Of A Lathe And The Quality Of The Finished Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you grind tools the wrong way, they won’t cut well. This can make the lathe, a machine we use to shape things, work poorly. You might end up with rough or uneven pieces instead of smooth ones. The finished workpiece might not fit properly or look nice. So, proper tool grinding is very important!”}}]}