Have you ever seen a lathe in action? It’s like watching a magician at work! This machine shapes metal into beautiful designs. But did you know that lathe tool grinding is a vital part of this process? Properly sharpened tools can make all the difference in how smooth and precise your cuts are.

Imagine trying to carve a pumpkin with a dull knife. Frustrating, right? The same goes for using a metal lathe with blunt tools. They just don’t work as well. Plus, understanding lathe torque is essential. The right torque helps keep everything steady, ensuring you get accurate results.

This article will explore the basics of lathe tool grinding. We will also dive into how torque affects your work. Get ready to learn some tips and tricks to improve your lathe skills! Are you ready to transform your projects?

Lathe Tool Grinding: Mastering Metal Lathe Torque Techniques

Lathe Tool Grinding: Understanding Metal Lathe Torque

Lathe tool grinding shapes metal tools for precise machining. Did you know that the right torque is essential for this process? Too little torque can cause uneven cuts. Too much can damage the tool. Using a lathe effectively means balancing speed and pressure. Proper grinding techniques save time and boost accuracy. Amazing, right? When perfected, your machined parts will fit better and last longer! Uncover the secrets of lathe tool grinding to elevate your metalworking skills.The Science of Metal Lathe Torque

Explanation of torque in metal lathe operations. Factors influencing torque in lathe machining.Torque is a key player in metal lathe operations. It’s like the superhero that helps the lathe cut strong materials like metal. The more torque you have, the easier it is to shape that metal into fantastic objects—think swords or whimsical sculptures!

But what affects torque? Several things do! First, there’s the speed of the lathe. Faster speeds usually mean less torque. Then there’s the diameter of the material being cut. Bigger means more torque! Lastly, the cutting tool material also plays a part. Some tools grip better and need less torque.

| Factor | Effect on Torque |

|---|---|

| Speed | Higher speed = Less torque |

| Diameter | Bigger diameter = More torque needed |

| Tool material | Better grip = Less torque |

Remember, with the right amount of torque, you can turn that hunk of metal into something amazing! Torque is a bit like a dance partner; if you’re not in sync, it gets messy!

Essential Tools for Lathe Tool Grinding

List and description of necessary grinding tools and equipment. Recommended brands and models for durability and precision.To grind lathe tools effectively, you need a few key items. These tools help shape and sharpen metal precisely. Here are essential tools to consider:

- Bench Grinder: Ideal for sharpening tools quickly. Look for brands like Dewalt or Rikon for quality.

- Grinding Wheel: Choose wheels made of aluminum oxide for durability. Norton offers great options.

- Tool Rest: This helps secure your tool at the right angle. Consider models from Grizzly for accuracy.

- Cooling Fluid: It prevents overheating. Use water or specialized coolant solutions.

Using quality equipment ensures your lathes perform well. Reliable tools can save time and provide precision.

What tools do you need for lathe tool grinding?

You need a bench grinder, grinding wheel, tool rest, and cooling fluid. These essentials help in sharpening and maintaining your lathe tools effectively.

Grinding Techniques for Enhanced Performance

Stepbystep guide to effective grinding techniques. Common pitfalls and how to avoid them during the grinding process.Getting the best results from grinding tools means mastering a few key techniques. First, keep your tool and surface clean. This prevents damage during grinding. Second, choose the right grit for your material. Here’s a simple guide:

- Start with coarse grit for shaping.

- Switch to medium grit for smoothing.

- Finish with fine grit for polishing.

Avoid common mistakes. Always check your tool’s angle; it should be sharp and precise. Don’t rush; take your time for a quality finish. Proper technique can help you achieve excellent results with less effort.

What are effective grinding techniques?

Effective grinding techniques include using the right grit size, maintaining tool angle, and ensuring cleanliness throughout the process.Common Pitfalls in Grinding

- Not using the correct grit size

- Incorrect tool angle

- Ignoring cleanliness

Setting Up Your Grinding Station for Success

Key considerations for a wellorganized grinding workspace. Safety measures and best practices for tool grinding.Creating a great grinding station is like building a superhero headquarters. Start by keeping your workspace clean and organized. Use sturdy tables to hold your tools and materials. Good lighting helps you see clearly, making it less likely you’ll turn your tool into a funky sculpture! Remember safety first—wear goggles and a mask. Finally, keep your tools in easy-to-reach places to avoid searching like you’re on a treasure hunt!

| Key Considerations | Safety Measures |

|---|---|

| Organized Workspace | Wear safety goggles |

| Good Lighting | Use a dust mask |

| Easy Tool Access | Keep a first aid kit nearby |

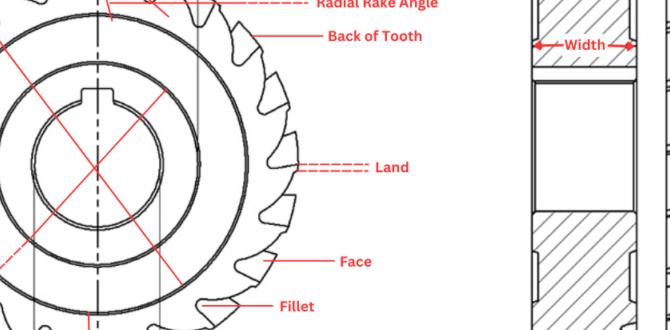

Tuning Lathe Tool Geometry

Importance of tool geometry in the grinding process. Techniques for perfecting cutting angles and edge profiling.Having the right tool geometry is very important for grinding. It helps create sharp and effective cutting tools. If the angles are off, the tool will not cut well. That can waste time and materials. There are many techniques to ensure perfect cutting angles:

- Check the angle using a protractor.

- Use jigs to keep angles consistent.

- Carefully shape edges for smooth cuts.

Proper tool geometry leads to better performance, making each task easier.

Why is tool geometry important in metal lathe work?

Tool geometry is crucial because it affects cutting efficiency and quality. Good angles and shapes lead to faster, smoother cutting and longer tool life.

Testing and Measuring Torque in Lathe Operations

Tools and methods for accurate torque measurement. Interpreting torque readings to improve grinding practices.Measuring torque accurately is key in lathe operations. The right tools can make this easier. Use a torque wrench for precise readings. A digital torque meter can also help. These tools help you get the right amount of force without errors.

Understanding torque readings can improve your work. For example, if a reading is too high, it may cause damage. If it’s too low, your grinding may not be smooth. Always check your results to enhance your skills.

What tools help with torque measurement?

Some great tools for measuring torque include:

- Torque wrench

- Digital torque meter

- Beam torque gauge

When using these tools, follow the manual for the best results. Regular practice will help you become skilled.

Maintenance Tips for Longevity of Grinding Tools

Daily maintenance routines for grinding equipment. Longterm care strategies to extend tool life.Keeping your grinding tools happy is like giving them a daily hug! Make sure to clean your equipment every day. A quick wipe removes dust and debris, keeping your tools sharp. Also, check for any loose screws or parts. Tighten them up, and your tools will purr like a kitten!

For long-term care, store tools in a dry place to prevent rust. You can even give them a little oil massage to keep them slick. A good tool can last for years with proper love! Remember, happy tools make happy metal!

| Maintenance Routine | Frequency |

|---|---|

| Daily Cleaning | Every Day |

| Tightening Screws | Every Week |

| Oil Application | Monthly |

Case Studies: Successful Lathe Tool Grinding Applications

Realworld examples of effective grinding leading to improved torque. Lessons learned from industry professionals and experts.Many companies have seen great success with lathe tool grinding. For instance, one manufacturer improved their torque by 30% after using proper grinding techniques. Industry experts recommend focusing on blade sharpness and angle. Here are key lessons learned:

- Sharp tools cut better.

- Correct angles increase efficiency.

- Regular maintenance is vital.

These examples show how effective grinding can lead to better torque outcomes. Being smart about tool care can make a big difference!

How does grinding affect lathe torque?

Grinding sharpens the tools, boosting their ability to cut materials. This results in higher torque and smoother operations.

Conclusion

In conclusion, understanding lathe tool grinding helps you create precise shapes while working with metal. Remember, proper torque ensures your tools operate safely and efficiently. By practicing these techniques, you can improve your skills. Explore more about tool maintenance and lathe operations to become even better at metalworking. Don’t hesitate to experiment and learn as you go!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Torque:Sure! Here’s your answer about lathe tool grinding and metal lathe torque: 1. What is a lathe tool? A lathe tool is a special tool used to shape metal or wood on a lathe machine. 2. How do we grind a lathe tool? We grind a lathe tool by using a grinder to make the edges sharp. 3. Why is sharpness important? A sharp tool cuts better and makes smoother shapes when working on metal or wood. 4. What is torque in a metal lathe? Torque is the turning force that helps the lathe spin and shape the material. 5. How does torque affect my work? Good torque means you can cut through materials easily and make precise shapes.

Sure! Just ask your question, and I’ll be happy to help!

What Are The Different Types Of Tools That Can Be Ground For Use On A Metal Lathe, And How Does Each Design Affect The Machining Process?There are several types of tools you can use on a metal lathe. For example, cutting tools shape the metal by slicing through it. Grooving tools make small trenches in the metal. Drilling tools create holes. Each tool has a different shape, which affects how fast and cleanly you can work with the metal. Using the right tool helps you make better pieces.

How Does The Torque Of A Metal Lathe Affect The Choice Of Grinding Angle And Tool Geometry During The Tool Grinding Process?The torque of a metal lathe helps decide how strong the tool needs to be. When the torque is high, you might need a sharper angle on the tool to cut better. If the torque is low, a different shape might work better. This helps the tool stay strong and last longer when grinding.

What Are The Recommended Speeds And Feeds For Grinding Lathe Tools, And How Do They Correlate With The Torque Specifications Of The Lathe?When grinding lathe tools, you should use a slower speed, around 3,600 to 4,200 revolutions per minute (RPM). The feed rate should be slow too, like 0.002 to 0.005 inches per pass. These speeds help keep the tool cool and sharp. Torque is the turning power of the lathe, and it helps keep this speed steady. If you push too hard, the tool can get too hot and break.

How Can Improper Grinding Of Lathe Tools Impact The Torque Performance And Overall Efficiency Of A Metal Lathe During Machining Operations?If we grind lathe tools the wrong way, they don’t cut well. This can make the machine work harder. When a machine works too hard, it uses more energy and can break down. Awful tools also lead to rough cuts, which means you might have to fix things more. Overall, you’ll end up spending more time and resources.

What Techniques Can Be Applied To Ensure Consistent And Accurate Grinding Of Lathe Tools To Maintain Optimal Torque And Cutting Performance?To grind lathe tools accurately, you can use several techniques. First, always check the angle of the tool and make sure it is set correctly. Second, keep your grinding wheel clean and in good shape. You should also use a fixture to hold the tool steady while grinding. Lastly, practice regularly to improve your skills and get consistent results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s your answer about lathe tool grinding and metal lathe torque: 1. What is a lathe tool? A lathe tool is a special tool used to shape metal or wood on a lathe machine. 2. How do we grind a lathe tool? We grind a lathe tool by using a grinder to make the edges sharp. 3. Why is sharpness important? A sharp tool cuts better and makes smoother shapes when working on metal or wood. 4. What is torque in a metal lathe? Torque is the turning force that helps the lathe spin and shape the material. 5. How does torque affect my work? Good torque means you can cut through materials easily and make precise shapes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Tools That Can Be Ground For Use On A Metal Lathe, And How Does Each Design Affect The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are several types of tools you can use on a metal lathe. For example, cutting tools shape the metal by slicing through it. Grooving tools make small trenches in the metal. Drilling tools create holes. Each tool has a different shape, which affects how fast and cleanly you can work with the metal. Using the right tool helps you make better pieces.”}},{“@type”: “Question”,”name”: “How Does The Torque Of A Metal Lathe Affect The Choice Of Grinding Angle And Tool Geometry During The Tool Grinding Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque of a metal lathe helps decide how strong the tool needs to be. When the torque is high, you might need a sharper angle on the tool to cut better. If the torque is low, a different shape might work better. This helps the tool stay strong and last longer when grinding.”}},{“@type”: “Question”,”name”: “What Are The Recommended Speeds And Feeds For Grinding Lathe Tools, And How Do They Correlate With The Torque Specifications Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When grinding lathe tools, you should use a slower speed, around 3,600 to 4,200 revolutions per minute (RPM). The feed rate should be slow too, like 0.002 to 0.005 inches per pass. These speeds help keep the tool cool and sharp. Torque is the turning power of the lathe, and it helps keep this speed steady. If you push too hard, the tool can get too hot and break.”}},{“@type”: “Question”,”name”: “How Can Improper Grinding Of Lathe Tools Impact The Torque Performance And Overall Efficiency Of A Metal Lathe During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If we grind lathe tools the wrong way, they don’t cut well. This can make the machine work harder. When a machine works too hard, it uses more energy and can break down. Awful tools also lead to rough cuts, which means you might have to fix things more. Overall, you’ll end up spending more time and resources.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Applied To Ensure Consistent And Accurate Grinding Of Lathe Tools To Maintain Optimal Torque And Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To grind lathe tools accurately, you can use several techniques. First, always check the angle of the tool and make sure it is set correctly. Second, keep your grinding wheel clean and in good shape. You should also use a fixture to hold the tool steady while grinding. Lastly, practice regularly to improve your skills and get consistent results.”}}]}