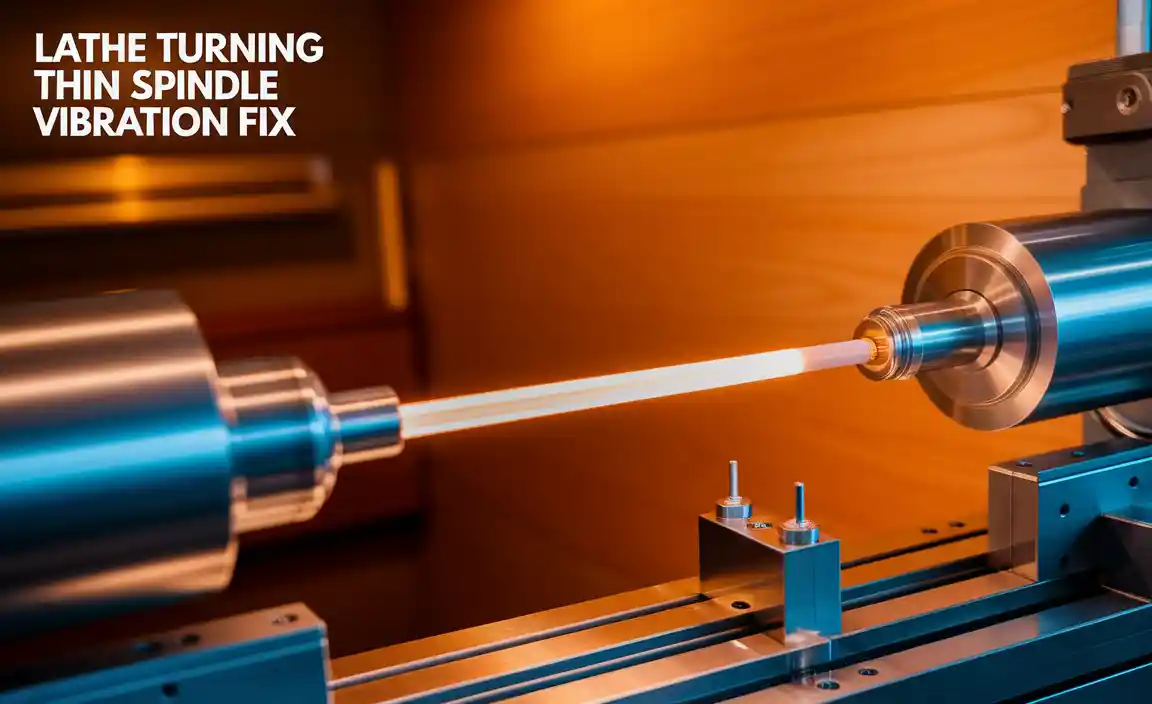

Have you ever tried to make something on a lathe, but it just didn’t turn out right? Maybe the cuts were uneven, or the tool just wouldn’t stay in the right position. This is where the lathe tool post shimming guide comes in handy!

Shimming can seem tricky at first. But it’s a simple way to fix those little mistakes. By adjusting the tool post, you can improve your projects and enjoy better results. Wouldn’t it be great if you could make one small change and see a big difference in your work?

Here’s a fun fact: even small adjustments can make your lathe work more smoothly. Think of it like tuning a musical instrument. If the strings are off, the music won’t sound right. In the same way, if your tool post isn’t set up correctly, your lathe might not perform its best.

In this guide, we will explore how to shim your lathe tool post. You’ll learn easy steps and helpful tips to make your projects shine. Let’s dive into the world of lathe tool post shimming and unlock the potential of your machine!

Comprehensive Lathe Tool Post Shimming Guide For Precision

Lathe Tool Post Shimming Guide

Shimming a lathe tool post helps improve precision. Did you know even small changes can make a big difference? This guide teaches you how to identify gaps and choose the right shim materials. You’ll learn simple tools to check alignment and how to adjust the height easily. Properly shimming can reduce vibrations and increase cutting efficiency. Whether you’re a beginner or experienced, mastering this technique will enhance your metalworking skills!Types of Lathe Tool Posts

Description of different types of tool posts: quickchange, standard, and more.. Pros and cons of each type in relation to shimming needs..There are different types of lathe tool posts, each with their own features. Quick-change tool posts let you swap tools fast, saving time. However, they may need careful shimming to ensure precision. Standard tool posts are simple and affordable. They can be harder to adjust sometimes. Here’s a quick look:

- Quick-Change Tool Post: Fast swapping of tools. More shimming needed.

- Standard Tool Post: Easy to use. Less adjustment, but slower to change tools.

- Heavy-Duty Tool Post: Great for tough materials. Can require more complex shimming.

Each type has its ups and downs. Choose the one that fits your work best.

What is a lathe tool post?

A lathe tool post holds the cutting tool while you work. A strong tool post helps make smooth cuts and shapes.

Types of lathe tool posts:

- Quick-change tool post

- Standard tool post

- Heavy-duty tool post

Reasons for Shimming Your Tool Post

Common issues caused by improper tool height and alignment.. Benefits of shimming for achieving accuracy in cuts..Improper tool height and alignment can cause many issues. The most common problems are uneven cuts and poor surface finish. This can lead to wasted materials and extra work. Shimming your tool post helps fix these problems. With shimming, you achieve better alignment, which brings more accuracy in cuts.

Some benefits of shimming include:

- Improved Accuracy: Precise cuts lead to better results.

- Smoother Surface: Less chatter means smoother finishes.

- Less Waste: You use your materials more effectively.

Why is tool height important?

Proper tool height ensures that your cuts are even and accurate. Without it, you can end up with uneven work.

Shimming your tool post is a simple action that leads to big improvements. It’s an essential part of using a lathe effectively.

Inspection and Preparation

Stepbystep guide on how to assess the need for shimming.. Tools required for effective inspection of tool post alignment..Before diving into shimming, a good inspection is key. Start by checking the tool post’s alignment. Use a dial gauge for precision. Make sure the tool post is level and has no visible damage. Next, gather your tools. You’ll need a straightedge and feeler gauges to measure gaps. Visual inspections are great, but don’t forget to trust your tools. They won’t judge you if you make a mistake! Here’s a quick table of the tools you’ll need:

| Tools Required | Purpose |

|---|---|

| Dial Gauge | For precise alignment checks |

| Straightedge | To check flatness |

| Feeler Gauges | To measure gaps |

Once you’re all geared up, assessing the need for shimming becomes much simpler!

Step-by-Step Shimming Process

Detailed procedure to shim a lathe tool post.. Common pitfalls and how to avoid them during the shimming process..Begin by measuring the tool post. Make sure it sits level on the cross-slide. Use shims to fill any gaps beneath. It’s like placing a thin pancake under a wobbly table. Next, tighten the bolts securely to hold everything in place. Watch out for common pitfalls! If the shims are too thick, your tool won’t align correctly. Remember: avoiding too much shim height keeps your cutting edge nice and sharp. Lastly, always double-check your setup—no one wants a surprise during a cut!

| Common Pitfalls | How to Avoid Them |

|---|---|

| Too thick shims | Use a thickness gauge |

| Loose bolts | Tighten fibers before cutting |

| Misalignment | Recheck level after shimming |

Testing the Setup Post-Shimming

Methods for confirming the correctness of the shimmed setup.. Recommended tests to ensure optimal tool performance..After shimming your lathe tool post, it’s important to test if everything is just right. You can do this by measuring the tool’s height and checking the movement. A simple way is to use a dial indicator. Place it on the tool and ensure it gives consistent readings. If it bounces around like a squirrel on espresso, you might need to adjust! Here’s a quick reference for reliable tests:

| Test | Purpose |

|---|---|

| Height Measurement | Checks tool alignment |

| Indicator Sweep | Assesses movement accuracy |

| Cut Quality Check | Ensures smooth operation |

By conducting these tests, you’re set for optimal tool performance. If things aren’t smooth, don’t despair! Just shim and test again. It’s like baking a cake—you might need to adjust the recipe a couple of times!

Maintenance Tips for Tool Post Shimming

Routine checks and adjustments to keep tool posts in perfect alignment.. When to reshim and how to recognize signs of wear or misalignment..Keeping your tool post in great shape is easy with regular checks. Look closely every few days. Make sure everything is tight and lined up right. If your tools make odd sounds or aren’t cutting well, it’s time to reshim. This means adding small pieces to fix alignment. Signs of wear include:

- Worn-out edges

- Inconsistent cuts

- Looseness in the tool post

When should you reshim a tool post?

You should reshim your tool post when you notice signs like uneven cuts or tool looseness. Regular checks help catch problems early. If you have to adjust often, it might be time to reshim.

Frequently Asked Questions about Tool Post Shimming

Common queries and industry insights regarding shimming practices.. Answers to misconceptions surrounding tool post setups..Many people wonder about tool post shimming. Some think it’s just extra work, but it’s very helpful! Here are a few common questions:

| Question | Answer |

|---|---|

| Why shim the tool post? | Shimming helps make your cuts smoother and more accurate! |

| Does shim size matter? | Yes! Smaller shims make tiny adjustments. |

| Can I use anything for shimming? | Only use materials that can handle pressure, like metal. |

Don’t let misconceptions trip you up. Proper shimming can be the difference between a great cut and a “Oops, I did it again” moment! And remember, if your tool post is level, your work will shine like a star!

Additional Resources and Tools

Recommended tools and equipment for efficient shimming.. Links to further reading, videos, or tutorials related to lathe tool post shimming..Shimming your lathe tool post can seem tricky, but having the right tools makes it a breeze! First off, a good pair of feeler gauges will help you measure gaps precisely. Also, consider a digital caliper for accuracy. And don’t forget the shims themselves! They come in various materials, like plastic or metal, to fit your needs. Check out videos online for visual tips; it’s like having a workshop buddy right in your pocket. You’ll be the shim champion in no time!

| Tool/Resource | Purpose | Link |

|---|---|---|

| Feeler Gauges | Measure gaps accurately | Learn More |

| Digital Caliper | Precise measurements | Learn More |

| Shims | Correct tool positions | Browse Options |

| Tutorial Videos | Visual guidance | Watch Here |

Conclusion

In summary, a lathe tool post shimming guide helps you adjust your lathe tool for better precision. Proper shimming improves your work quality. Remember to check your setup often for the best results. You can find more tips online or in books about lathe operation. Start practicing today to enhance your skills and create amazing projects!FAQs

What Are The Common Signs That Indicate A Lathe Tool Post Needs Shimming?You might notice your cuts are uneven or rough. If the tool slips while working, that’s another sign. Sometimes, the tool doesn’t touch the material straight. If you see these problems, it’s time to check if the tool post needs shimming. Shimming helps keep everything aligned and working well.

How Do You Determine The Correct Thickness Of Shim Material For A Lathe Tool Post?To find the right thickness of shim for a lathe tool post, first, check the height of the tool. Measure how much higher or lower you want the tool to be. Then, choose a shim that matches that gap. You can stack shims if you need more thickness. Finally, test it to see if the tool cuts correctly.

What Types Of Materials Are Best Suited For Making Shims For Lathe Tool Posts?You can make shims for lathe tool posts from materials like metal, plastic, or wood. Metal shims are strong and last a long time. Plastic shims are lightweight and easy to cut. Wood can work, but it’s not as strong as metal or plastic. Choose the material based on how much support you need!

How Can Improper Shimming Of A Tool Post Affect Workpiece Accuracy And Finish Quality?If you don’t shim the tool post correctly, it can wobble. This makes the tool move around when you’re working. As a result, the shape of your workpiece can be off, and it might not fit right. You could also end up with rough surfaces, making the finish look bad. Always check your shimming to keep your work nice and neat!

What Step-By-Step Process Should Be Followed To Properly Shim A Lathe Tool Post?To shim a lathe tool post, follow these steps: 1. First, turn off the lathe and remove the tool post. 2. Next, check the base and the area where it sits. 3. Use thin pieces of metal or plastic as shims. 4. Place the shims under the tool post to level it. 5. Finally, tighten everything back up and check the tool’s position.