Have you ever watched a woodturner create a beautiful piece of art? It’s amazing how a simple block can turn into something stunning. But did you know that proper lathe tool rest alignment is key to making those perfect cuts? Without it, your project might not turn out as expected.

Imagine trying to carve a smooth bowl, but your tools keep bouncing around. Frustrating, right? Getting the alignment just right helps you create clean lines and smooth surfaces. It’s like having a buddy support you while you work.

Many beginners overlook this step, thinking it’s not important. But that’s a big mistake. Studies show that proper tool rest alignment can save you time and wood. Who wouldn’t want to get better results more quickly?

In this article, we will explore how to align your lathe tool rest correctly. You’ll learn tips and techniques that will make a huge difference in your projects. So, let’s dive in and see how alignment can transform your woodworking experience!

Lathe Tool Rest Alignment: Essential Techniques For Precision

Lathe Tool Rest Alignment

Proper lathe tool rest alignment is crucial for smooth and accurate turning. Misaligned tool rests can lead to poor cuts and safety hazards. Did you know that just a small wobble can ruin your project? Aligning the tool rest ensures consistent depth and control. Setting it at the right height can greatly improve your crafting experience. So, take a moment to check your setup before starting. It could make all the difference in achieving perfect results!Understanding Lathe Tool Rest Alignment

Definition and importance of tool rest alignment. Common issues caused by misalignment.Lathe tool rest alignment is the process of setting up the tool rest in the right position for effective and safe woodworking. It’s super important because a well-aligned tool rest leads to smoother cuts and reduces accidents. If it’s off, you might end up with rough surfaces, wasted materials, or worse—a tool that flies off like a startled cat! Check out common problems from misalignment in the table below:

| Issue | Result |

|---|---|

| Inconsistent Cuts | Uneven surfaces that look like they’ve been through a bumpy road. |

| Increased Tool Wear | Faster dulling of tools, making them less effective (and grumpy). |

| Higher Risk of Accidents | More chances of tools getting out of control (like a bad rollercoaster). |

So, keep that tool rest aligned and your projects will thank you!

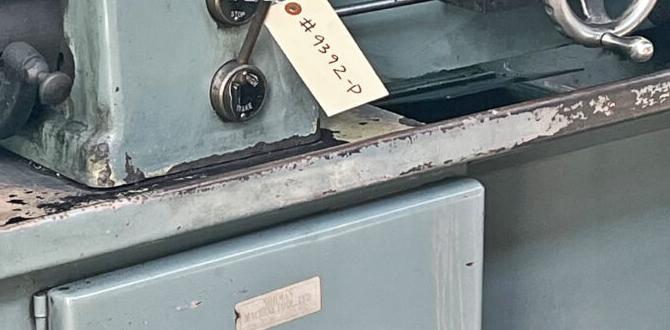

Tools and Equipment for Alignment

Essential tools for aligning tool rests. Recommended equipment for optimal precision.To align tool rests on a lathe, you need some trusty friends—tools that make the job easier! First on the list is a caliper. This nifty tool measures with precision. Next, grab a straightedge; it helps to ensure everything lines up nicely. A level is also important to avoid any wonky angles. Finally, the beloved hex key is a must-have for adjusting those stubborn screws.

| Tool | Purpose |

|---|---|

| Caliper | Precision measurements |

| Straightedge | Ensures straight alignment |

| Level | Checks for flatness |

| Hex Key | Adjusts screws easily |

With these tools in hand, you’ll have everything you need for a smooth alignment. Remember, precision is key, and a little laugh helps too—because who doesn’t love a well-aligned lathe that makes beautiful projects? Happy turning!

Steps to Properly Align Your Lathe Tool Rest

Detailed stepbystep alignment process. Tips for achieving accuracy during alignment.Aligning your lathe tool rest is like getting your shoes tied just right—too loose or too tight can mess everything up! Start by loosening the tool rest. Next, place a straight edge across the lathe bed and adjust until the rest is level. Always double-check with a ruler for accuracy: measure twice, cut once! A slight misalignment can lead to chips and splinters, so be precise!

| Step | Action |

|---|---|

| 1 | Loosen the tool rest. |

| 2 | Use a straight edge on the lathe bed. |

| 3 | Adjust until level. |

| 4 | Check with a ruler! |

Remember, even tiny misalignments can ruin your masterpiece. So, pay attention and keep your tools sharp and happy!

Common Mistakes in Tool Rest Alignment

Frequently encountered errors and how to avoid them. Consequences of improper alignment.Many people make simple mistakes with their tool rest alignment. One common error is setting it too high or too low. This can lead to uneven cuts, making your work look like a toddler’s art project! Another frequent blunder is failing to check for tightness. A loose tool rest can wobble like a jelly on a spring, ruining your piece. Improper alignment can cause dangerous kickbacks too. Avoid these pitfalls and keep your projects smooth and safe!

| Common Mistake | How to Avoid | Consequences |

|---|---|---|

| Incorrect height | Adjust it precisely | Uneven cuts |

| Loose tool rest | Check tightness regularly | Wobbly tools |

| Lack of checking | Always double-check | Potential kickbacks |

Advanced Techniques for Experienced Turners

Techniques for finetuning tool rest alignment. Using advanced tools for increased precision.Fine-tuning your tool rest alignment can help you work better. Here are some advanced techniques:

- Use a caliper for precise measurements.

- Look for a laser level to check the alignment easily.

- Adjust the height until the tool sits perfectly.

- Experiment with different rest angles to find what works best.

These steps can make your lathe projects smoother and more fun. Remember, practice leads to great results!

What tools can help with lathe tool rest alignment?

Advanced tools like calipers and laser levels work best for precise alignment. They help ensure your tool rest is just right for every project.

Maintaining Alignment over Time

Best practices for keeping your tool rest aligned. Signs that your alignment may need rechecking.Keeping your lathe tool rest aligned is like keeping your shoes tied—very important! Regular checks can save you from wobbly tools and unwanted accidents. Best practices include checking alignment every few uses and using a level to make sure everything’s even. Watch out for signs like uneven cuts or weird vibrations; they mean it’s time for a check-up.

| Signs to Check | What to Do |

|---|---|

| Uneven Cuts | Recheck your alignment |

| Strange Vibrations | Loosen and adjust the tool rest |

| Frequent Tool Dulling | Look for misalignment adjustments |

Remember, an aligned tool rest is a happy tool rest. Keep your lathe singing smoothly, and you’ll turn out great work every time!

Frequently Asked Questions

Common queries related to tool rest alignment. Expert answers to enhance understanding.Have questions about keeping your lathe tool rest aligned? You’re not alone! People often wonder how to check or fix their tool rest, what tools to use, and why alignment matters. Here’s a fun fact: poor alignment could lead to wobbly results, like a bad dance move! Below are answers to common queries that can help you keep your woodworking on point:

| Question | Answer |

|---|---|

| Why is tool rest alignment important? | It keeps your wood sturdy and makes your work look professional! |

| How to check alignment? | Use a straightedge or a reliable measuring tool. |

| What tools do I need? | A wrench and a level are your best friends here! |

So remember, a well-aligned tool rest is your secret weapon for perfect projects!

Conclusion

In summary, proper lathe tool rest alignment is crucial for smooth turning. It helps you create better shapes and finish your projects faster. Remember to check the alignment regularly. This will improve your skills and make woodworking easier. For more tips, consider reading about lathe techniques and tool maintenance. Let’s create amazing pieces together!FAQs

Sure! Here Are Five Questions Related To Lathe Tool Rest Alignment:Sure! Here are some simple answers to questions about lathe tool rest alignment: 1. Why is it important to align the tool rest? It’s important because a straight tool rest helps you cut smooth shapes. It keeps your tools stable while you work. 2. How do you check if the tool rest is level? You can use a ruler or a level. Just place it on the tool rest and see if it’s even. 3. What happens if the tool rest is too low? If it’s too low, your tool won’t cut well. You might struggle to make good designs. 4. How can you adjust the tool rest height? You can raise or lower it using screws. Make sure to check it again after adjusting. 5. When should you check the alignment of the tool rest? You should check it every time you use the lathe. This makes sure your work stays safe and looks good!

Of course! Please provide the section or question you’d like me to answer, and I’ll be happy to help.

What Is The Importance Of Proper Tool Rest Alignment In Lathe Operations?Proper tool rest alignment helps us make better shapes when using a lathe. When it is set right, the tool moves smoothly and easily. This keeps the workpiece safe and prevents damage. It also helps us get the results we want faster and makes our work look nice.

How Can You Determine If Your Tool Rest Is Aligned Correctly With The Lathe Spindle?To check if your tool rest is lined up with the lathe spindle, you can use a piece of wood. Place the wood against the tool rest and spin the lathe. If the wood touches the tool rest evenly as it turns, it is aligned well. If it wobbles or hits in one spot, you need to adjust it. Keep adjusting until it turns smoothly!

What Techniques Can Be Used To Adjust The Height And Position Of A Lathe Tool Rest For Optimal Performance?To adjust the height of a lathe tool rest, you can loosen the knobs and raise or lower it. Make sure it’s close to the piece you are working on. For the position, slide it back and forth to find what feels best. Check that it is steady before you start working. This helps you make better shapes and cuts.

What Are Common Signs Of Misalignment In A Lathe Tool Rest, And How Can They Affect The Machining Process?Common signs of misalignment in a lathe tool rest include uneven cuts and vibrations. You might also notice that the tool doesn’t stay in place easily. This can make it hard to shape your workpiece properly. Bad alignment can cause mistakes, making your project take longer to finish.

How Often Should You Check And Recalibrate The Alignment Of Your Lathe Tool Rest For Consistent Results?You should check and adjust your lathe tool rest often. It’s good to do this every time you start using your lathe. If you notice problems with your work, check it again. Keeping it aligned helps you make better, smoother cuts. This way, your projects will turn out great!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Tool Rest Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some simple answers to questions about lathe tool rest alignment: 1. Why is it important to align the tool rest? It’s important because a straight tool rest helps you cut smooth shapes. It keeps your tools stable while you work. 2. How do you check if the tool rest is level? You can use a ruler or a level. Just place it on the tool rest and see if it’s even. 3. What happens if the tool rest is too low? If it’s too low, your tool won’t cut well. You might struggle to make good designs. 4. How can you adjust the tool rest height? You can raise or lower it using screws. Make sure to check it again after adjusting. 5. When should you check the alignment of the tool rest? You should check it every time you use the lathe. This makes sure your work stays safe and looks good!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the section or question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Importance Of Proper Tool Rest Alignment In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper tool rest alignment helps us make better shapes when using a lathe. When it is set right, the tool moves smoothly and easily. This keeps the workpiece safe and prevents damage. It also helps us get the results we want faster and makes our work look nice.”}},{“@type”: “Question”,”name”: “How Can You Determine If Your Tool Rest Is Aligned Correctly With The Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your tool rest is lined up with the lathe spindle, you can use a piece of wood. Place the wood against the tool rest and spin the lathe. If the wood touches the tool rest evenly as it turns, it is aligned well. If it wobbles or hits in one spot, you need to adjust it. Keep adjusting until it turns smoothly!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Adjust The Height And Position Of A Lathe Tool Rest For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the height of a lathe tool rest, you can loosen the knobs and raise or lower it. Make sure it’s close to the piece you are working on. For the position, slide it back and forth to find what feels best. Check that it is steady before you start working. This helps you make better shapes and cuts.”}},{“@type”: “Question”,”name”: “What Are Common Signs Of Misalignment In A Lathe Tool Rest, And How Can They Affect The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of misalignment in a lathe tool rest include uneven cuts and vibrations. You might also notice that the tool doesn’t stay in place easily. This can make it hard to shape your workpiece properly. Bad alignment can cause mistakes, making your project take longer to finish.”}},{“@type”: “Question”,”name”: “How Often Should You Check And Recalibrate The Alignment Of Your Lathe Tool Rest For Consistent Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check and adjust your lathe tool rest often. It’s good to do this every time you start using your lathe. If you notice problems with your work, check it again. Keeping it aligned helps you make better, smoother cuts. This way, your projects will turn out great!”}}]}