Do you want to keep your lathe tools sharp and ready for action? Have you ever struggled with dull blades that just won’t cut? If so, you’re in the right place. Learning how to sharpen lathe tools with a bench grinder can make a big difference in your woodworking projects.

Imagine turning a simple block of wood into a beautiful piece of art. But what happens when your tools don’t cooperate? A dull tool can ruin your work and waste your time. That’s where sharpening comes in. It’s not just about keeping your tools in shape; it’s about improving the quality of your work.

Here’s a fun fact: Many woodworkers find that sharpening their tools regularly is just as important as using them. They say that a sharp lathe tool can make all the difference. So, are you ready to learn the tricks of sharpening with a bench grinder?

This article will guide you through the easy steps to sharpen your lathe tools. By the end, you’ll feel confident and ready to tackle any project with sharp, effective tools.

Lathe Tool Sharpening With Bench Grinder: A Comprehensive Guide

Lathe Tool Sharpening with Bench Grinder

Sharpening lathe tools with a bench grinder can improve your woodworking skills. Many people struggle with dull blades. Did you know that a properly sharpened tool can make cutting smoother? Start by setting the right angle on your grinder, usually around 20 degrees. Use water to cool the tool while sharpening. This prevents overheating, which can ruin the metal. Regular sharpening not only saves time but enhances the quality of your work, making every project better!Essential Tools and Equipment for Sharpening

List of necessary equipment, including bench grinder specifications. Additional tools that enhance the sharpening process.To sharpen lathe tools effectively, you’ll need some key equipment. A bench grinder is essential. Look for one with a powerful motor, ideally around 3/4 to 1 horse power. The wheels should be on the medium or fine grit side. Here’s a short list of other handy tools:

- Diamond wheel dresser

- Safety goggles

- Clamping devices

- Measuring tools

These tools will make sharpening easier and safer. For a smooth process, always ensure your workspace is clean and well-lit.

What type of bench grinder should I use for sharpening tools?

Choose a bench grinder with a strong motor and suitable grit wheels. A medium or fine grit wheel works best for sharpening lathe tools.

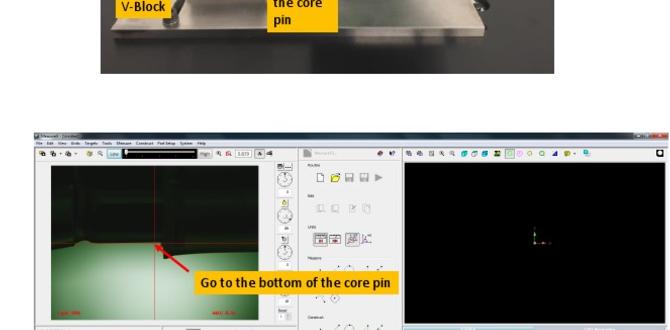

Setting Up Your Bench Grinder

Stepbystep guide on adjusting the grinder for optimal sharpening angles. Safety measures and maintenance tips for bench grinders.First, make sure your bench grinder is on a stable surface. This prevents wobbles that could ruin your sharpening. Next, adjust the tool rest. Aim for about a 15° to 30° angle for the best results. Use a square to check if it’s straight. Safety comes first! Always wear eye protection to keep sparks out of your eyes. And don’t forget to keep the grinder clean and lubricated to make it last longer. Regular maintenance is key!

| Setup Step | Adjustment Tips |

|---|---|

| Stability | Ensure the grinder is on a flat surface. |

| Tool Rest Angle | Adjust for a 15° to 30° angle. |

| Safety Gear | Always wear eye protection. |

| Maintenance | Keep the grinder clean and lubricated. |

Sharpening Techniques for Lathe Tools

Detailed explanation of different sharpening techniques (e.g., angle, pressure). Common mistakes to avoid during the sharpening process.Sharpening lathe tools can be tricky. First, hold the tool at a proper angle, usually around 25-30 degrees. Too much pressure can lead to dullness, while too little may not sharpen at all. Watch out for common mistakes like using a worn-out wheel, which can turn your tool into a butter knife! Remember, practice makes perfect, but keep your fingers away from the wheel—they’re not the star of the show!

| Technique | Angle | Pressure |

|---|---|---|

| Standard Sharpening | 25-30 degrees | Moderate |

| Honing | 15 degrees | Light |

| Rough Shaping | 30-45 degrees | High |

Maintaining Lathe Tools Post-Sharpening

Best practices for caring and storing sharp lathe tools. How to recognize when tools need sharpening again.Once you’ve sharpened your lathe tools, keeping them in tip-top shape is key. Store them in a dry, safe place to prevent rust. Use a toolbox or drawer to keep them organized. This way, you won’t poke your finger while rummaging around! Look for signs like dullness or uneven cuts; that means it’s time for a touch-up again. Regular checks help you stay sharp! It’s just like checking if your shoes need polishing. Keep your tools happy!

| Signs Tools Need Sharpening | Best Care Practices |

|---|---|

| Dull edges | Store in a dry spot |

| Uneven cuts | Use a toolbox for storage |

| Visible rust | Regular cleaning |

Bench Grinder Accessories for Enhanced Sharpening

Recommended accessories and attachments to improve efficiency. Benefits of using jigs and fixtures for consistent results.To amp up your sharpening game, consider a few handy accessories. A sharpening jig helps hold your tool in place. This means more consistent results every time. Use a coolant attachment to keep things cool. Nobody wants a hot tool, right? For even better results, a grinding wheel can also save you time. With these gadgets, you’ll be sharpening like a pro, or at least like someone who passed a class on it!

| Accessory | Benefit |

|---|---|

| Sharpening Jig | Consistent Results |

| Coolant Attachment | Prevents Heat Damage |

| Grinding Wheel | Saves Time |

Troubleshooting Common Sharpening Issues

Identification of frequent sharpening problems and their solutions. Tips for achieving a smoother finish and sharper edge.Sharpening tools can sometimes feel like a puzzle. First, check if your tool is unevenly sharpened or leaves rough edges. That could mean your angle is off. Always try to keep a consistent angle while sharpening to improve your results. If the tool gets too hot, it can lose its edge. Use cool water to keep it chill! Remember, a smooth finish starts with a sharp edge. Here’s a quick troubleshooting table:

| Issue | Solution |

|---|---|

| Uneven edges | Check your angle |

| Hot tool | Use water for cooling |

| Dull finish | Sharpen at a steady pace |

Remember, even the best tools need a little TLC. Keep calm and sharpen on!

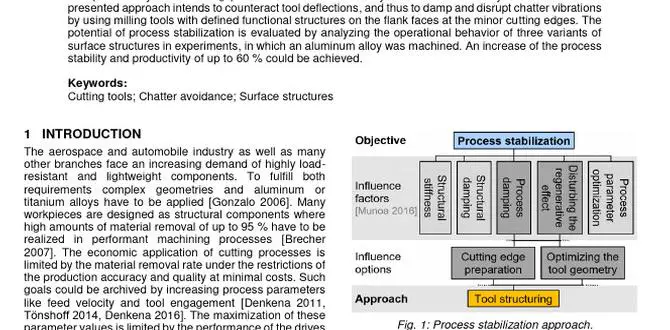

Real-World Applications and Case Studies

Examples of projects benefiting from proper tool sharpening. Testimonials and experiences from woodturning enthusiasts who utilize sharpened tools.Many woodturning projects show why sharp tools are key. For instance, turners who make bowls often sing praises about their experience with sharpened tools. They claim that a fine edge makes it easier to shape wood exactly like a chef who loves his sharp knives. It’s less effort and more fun! A sharp tool helps you finish projects faster and with fewer mistakes.

| Project Type | Benefits of Sharpening |

|---|---|

| Bowls | Precision shaping and smoother finishes |

| Spindles | Less tear-out and improved details |

| Boxes | Faster assembly and cleaner cuts |

One woodturning enthusiast said, “Sharpened tools are like magic wands! They turn ordinary wood into stunning pieces.” Stories like these are common. Sharp tools truly transform crafting and make every woodturner feel like a pro!

Conclusion

In conclusion, sharpening lathe tools with a bench grinder is an essential skill. It keeps your tools effective and extends their life. Remember to set the correct angle and use light pressure while sharpening. Practice regularly for the best results. You can find more tips online to perfect your technique. Start sharpening today and enjoy better woodworking!FAQs

What Is The Proper Angle For Sharpening Lathe Tools On A Bench Grinder?You should sharpen lathe tools at a 20 to 30-degree angle on a bench grinder. This angle helps the tools cut well. Keep the tool steady while you work. Always be careful around the grinder, as it can be dangerous. You want your tools to be sharp and safe!

How Can I Determine The Best Grinding Wheel For Sharpening Different Types Of Lathe Tools?To find the best grinding wheel for sharpening your lathe tools, first look at the tool material. For high-speed steel tools, use a wheel with aluminum oxide. If your tools are made of carbide, choose a diamond wheel. Check the wheel’s grit size too; finer grit is good for a smooth finish, while coarser grit shapes faster. Always follow safety rules when grinding!

What Safety Precautions Should Be Taken When Sharpening Lathe Tools On A Bench Grinder?When sharpening lathe tools on a bench grinder, we should wear safety goggles to protect our eyes. You should also wear gloves to keep your hands safe. Always keep your hair tied back and clothes fitted so they won’t get caught in the machine. Make sure to stand to the side of the grinder when it’s running. Lastly, check that the grinder is stable before you use it.

How Do I Maintain The Correct Tool Geometry While Sharpening Lathe Tools On A Bench Grinder?To keep the right shape on your lathe tools while using a bench grinder, you should do a few simple things. First, hold the tool at the same angle every time you sharpen it. You can use a tool rest as a guide. Also, check your tool shape often to make sure it isn’t getting too rounded. Finally, don’t press too hard against the grinder; let it do the work.

What Techniques Can I Use To Achieve A Keen Edge On My Lathe Tools During The Sharpening Process?To sharpen your lathe tools, you can use a sharpening stone or a grinder. First, hold the tool at a steady angle against the stone or grinder. Move it back and forth to create a sharp edge. Check the sharpness by lightly touching the edge with your finger. If it feels smooth and sharp, you’re done!