Have you ever watched a craftsman work with a lathe? It’s fascinating to see how a simple piece of wood or metal transforms into something beautiful and useful. A big part of that magic happens at the toolpost. Lathe toolpost quick change types can make this process even smoother and faster.

Imagine you’re in a workshop. You need to switch from one cutting tool to another. If you have a quick change toolpost, you can do this in seconds! Isn’t that exciting? Knowing the different types of lathe toolposts can help you choose the best one for your needs.

There are many styles available. Each has its own benefits and features. Some are designed for beginners, while others are for experts. Did you know that using the right toolpost can make your projects safer and more enjoyable? So, whether you’re a hobbyist or a pro, understanding lathe toolpost quick change types is important.

Let’s explore these types together and discover how they can enhance your lathe experience.

Lathe Toolpost Quick Change Types: An Overview Of Variants

Lathe Toolpost Quick Change Types

Lathe toolpost quick change types help improve efficiency in workshops. These tools allow users to switch cutting tools quickly and easily. There are several designs, including wedge-style and cam-lock systems. Each has unique benefits, like stability and speed. Imagine finishing projects faster without fussing over tool adjustments! Fun fact: using a quick change toolpost can save hours of work over a month. Choose the right type to enhance your turning experience!Understanding Lathe Toolposts

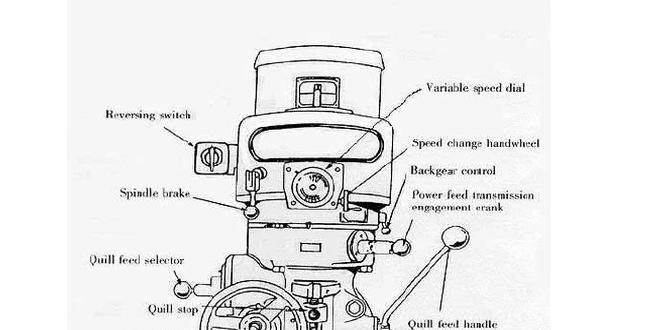

Definition and purpose of a lathe toolpost. Importance of quick change toolposts in modern machining.A lathe toolpost is a part that holds tools on a lathe machine. It allows quick tool changes without losing time. Think of it as the lathe’s assistant, always ready to help with different tasks. Quick change toolposts are super important in modern machining. They let machinists switch tools fast, helping to save time and keep projects running smoothly. In fact, using these toolposts can speed up work by up to 50%! Now, that’s a reason to smile while working!

| Type | Benefits |

|---|---|

| Quick Change | Fast switching saves time |

| Standard Toolpost | Simple use but slower |

| Multi-Position | Offers more angles |

Benefits of Quick Change Toolposts

Increased efficiency and productivity in machining processes. Enhanced precision and consistency in tool alignment.Switching tools is like changing socks—quick and easy is the way to go! Quick change toolposts make machining faster. They save time, letting machinists work more efficiently. You’ll get more done in less time. Plus, they enhance how tools are lined up. This means parts will fit better and work properly. Precision is key! With these toolposts, consistency in cuts improves, leading to quality parts. Think less time fumbling, more time creating! Who knew tool changing could feel this smooth?

| Benefit | Description |

|---|---|

| Efficiency | Faster tool changes mean more production. |

| Precision | Better alignment creates quality parts. |

Key Features to Consider

Adjustability and locking mechanisms. Compatibility with various lathe models.Choosing the right lathe toolpost can make a big difference. Look for these key features:

- Adjustability: This helps you change tools quickly. A good system lets you adjust without hassle.

- Locking Mechanisms: Ensure that tools stay in place. A strong locking system gives you safety and stability.

- Compatibility: Make sure it fits your lathe model. Different lathes may need different toolposts.

When you know these features, you can pick the best toolpost. Simple choices lead to better projects!

What should I look for in a lathe toolpost?

Look for adjustability, strong locking mechanisms, and compatibility with your lathe model. These features ensure you work safely and efficiently.

Popular Brands and Models

Review of leading manufacturers in the market. Comparison of model specifications and pricing.Many brands make toolposts that can quickly change tools. Some of the leading names include:

- Phase II – Known for its strong parts and fair prices.

- Aloris – Offers high quality but is often pricier.

- South Bend – A classic choice with many options.

What are the best lathe toolpost brands?

The best brands include Phase II, Aloris, and South Bend. Each has unique benefits that suit different needs. Choose one based on your budget and requirements.

Installation and Maintenance Tips

Stepbystep guide for installing quick change toolposts. Best practices for maintaining toolposts for longevity.Installing a quick change toolpost is simple and can be done in a few steps. First, gather your tools. Then, remove the existing toolpost from the lathe. Next, align the new toolpost and secure it with screws. Finally, check that it moves smoothly. For maintenance, always keep it clean. Lubricate it regularly to avoid rust. Tightening loose parts can also help it last longer.

How can I maintain my toolpost?

To keep your toolpost working well, follow these tips:

- Clean it often.

- Apply oil for smooth operation.

- Tighten any loose screws.

- Store it in a dry place.

Common Issues and Solutions

Troubleshooting frequent problems encountered with toolposts. Preventative measures to avoid toolpost issues.Toolposts can sometimes cause problems. Common issues include misalignment and difficulty in changing tools. Misalignment can lead to poor cuts. To avoid this, check for tight connections regularly. Also, clean the toolpost often. Here are some quick solutions:

- Check tightness regularly.

- Clean parts often to reduce buildup.

- Lubricate moving parts for smooth operation.

By following these steps, users can keep toolposts working well and avoid frustration.

What are common lathe toolpost problems?

Common problems include misalignment, tool slipping, and difficulty switching tools. Always check connections and clean the toolpost to prevent these issues.

How can I prevent toolpost issues?

Regular maintenance, like lubrication and cleaning, helps avoid toolpost problems. Proper care can extend the life of your toolpost.

Tools and Accessories for Optimal Use

Recommended tools to enhance the performance of quick change toolposts. Accessories that complement toolpost systems.To make the most of your quick change toolpost, use strong tools. Here are some recommended items:

- Cutting tools: High-speed steel or carbide tools are great choices.

- Tool holder: A sturdy tool holder keeps tools secure.

- Measuring tools: Calipers and micrometers help ensure accuracy.

- Coolant system: Proper cooling prevents overheating and tool wear.

Accessories can also boost your toolpost system. Consider items like tool organizers and chucks. They keep everything neat and easy to access. Having the right tools and accessories leads to better performance!

What tools enhance the performance of quick change toolposts?

Cutting tools, tool holders, measuring tools, and coolant systems enhance the performance of quick change toolposts.

Expert Advice and Best Practices

Insights from industry professionals on toolpost selection. Best practices for using quick change toolposts effectively.Choosing the right toolpost matters for your lathe work. Professionals suggest looking for durability and ease of use. Here are some tips:

- Pick a toolpost that fits your lathe well.

- Ensure it allows for quick changes, saving you time.

- Regularly check and maintain it for best performance.

- Practice using it until you feel comfortable.

Following these simple steps can lead to better results and smoother machining. Remember, the right tool can make your projects easier and more fun!

What are the benefits of quick change toolposts?

Quick change toolposts save time and increase accuracy. They allow for fast adjustments without tools, keeping your work flowing smoothly. This means less waiting and more creating!

Conclusion

In summary, lathe toolpost quick change types make your work easier and faster. You can switch tools quickly, saving time on projects. Remember that different types suit different lathes and tasks. Explore your options to find the best fit for you. For more tips, check out guides or videos online. Happy tooling!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Toolpost Quick Change Types:Sure! Quick change toolposts are special parts on lathes that help you change tools quickly. There are different types, like the cam lock and wedge type. Each type helps you switch tools without much hassle. Knowing which one to use can make your work easier and faster. It’s fun to learn how they work!

Sure! Please give me the question you’d like me to answer.

What Are The Main Advantages Of Using A Quick Change Toolpost Compared To A Traditional Toolpost On A Lathe?A quick change toolpost lets you swap tools fast. You can switch tools with just a lever instead of using screws. This saves time when you’re working on projects. It also makes it easier to use different tools quickly. This means you can finish your work faster and have more fun!

How Do Different Types Of Quick Change Toolposts, Such As Wedge-Type And Cam-Lock Toolposts, Compare In Terms Of Ease Of Use And Precision?Wedge-type and cam-lock toolposts help you change tools quickly on a machine. Wedge-type toolposts are easy to use because they lock tight and hold tools well. Cam-lock toolposts are also simple but might not hold as firmly for very detailed work. Both types work well, but wedge-type is usually better for precise jobs.

What Factors Should Be Considered When Selecting The Appropriate Quick Change Toolpost For A Specific Lathe Model?When choosing a quick change toolpost for your lathe, you need to think about a few things. First, check the size of your lathe. It should match so it fits well. Then, look at the types of tools you want to use with it. Make sure the toolpost can hold those tools. Lastly, think about how easy it is to change tools quickly. You want it to work smoothly and save you time.

How Do Quick Change Toolposts Enhance The Efficiency And Productivity Of Lathe Operations In A Workshop Setting?Quick change toolposts help us switch tools on a lathe quickly. This saves us time when we need to change tasks. Instead of wasting time unscrewing tools, we can just pull one out and put another in. This way, we can make more items in less time. Overall, it makes our work faster and easier, boosting our productivity.

What Maintenance Practices Are Recommended To Ensure The Longevity And Accuracy Of A Quick Change Toolpost On A Lathe?To keep your quick change toolpost on a lathe working well, clean it regularly. Use a soft cloth to wipe off any dirt or chips. Make sure the moving parts are oiled, so they move smoothly. Check for loose screws and tighten them if needed. Finally, store your lathe in a dry place to prevent rust.