Have you ever watched a metal lathe spin? It’s fascinating! A lathe can shape metal into amazing projects. But to use it safely and effectively, proper training is essential. That’s where a lathe training course comes in.

Imagine learning to create your own metal projects. What if you could make custom parts or art? With the right skills, it can become a fun hobby or even a career.

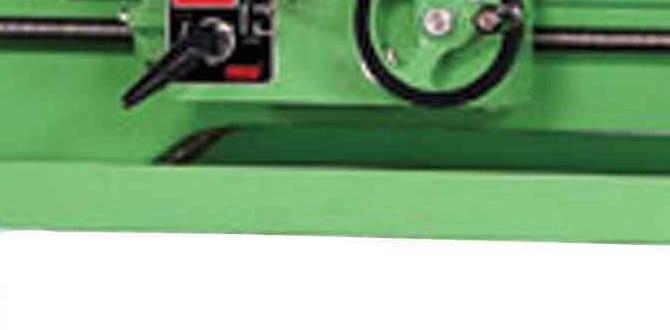

The carriage is a key part of the metal lathe. It holds the workpiece in place during cutting. Understanding how it works is vital for any lathe operator. A lathe training course focuses on this and much more.

Did you know that many people turn to metalworking as a relaxing pastime? Learning to master the lathe can bring a lot of joy and satisfaction. Are you ready to start your journey with metal lathes and see what you can create?

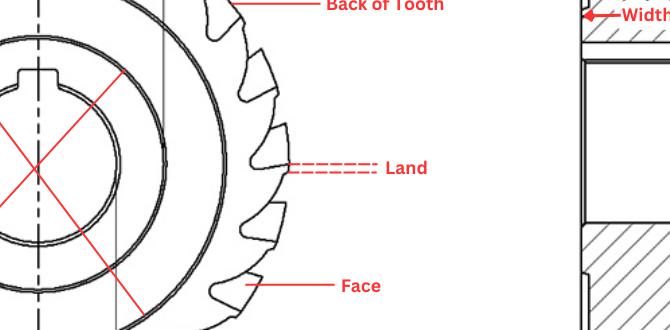

Lathe Training Course: Mastering Metal Lathe Carriage Skills Lathe Training Courses Have Become Essential For Anyone Looking To Enhance Their Skills In Metalworking, Specifically When It Comes To Operating A Metal Lathe And Understanding The Intricacies Of The Metal Lathe Carriage. In This Article, We Will Explore What A Lathe Training Course Entails, Its Importance, And How Mastering The Metal Lathe Carriage Can Elevate Your Machining Expertise. What Is A Lathe Training Course? A Lathe Training Course Is Designed To Provide Individuals With Hands-On Experience And Theoretical Knowledge About Operating A Lathe Machine. These Courses Cover Various Aspects, Including Safety Protocols, Machine Setup, Tool Selection, And Specific Techniques. Importance Of Learning About The Metal Lathe Carriage The Metal Lathe Carriage Is A Critical Component Of The Lathe Machine That Supports And Moves The Cutting Tool. Understanding Its Mechanics And Operation Is Vital For Anyone Involved In Machining Metals. Mastering The Metal Lathe Carriage Allows Operators To Achieve Precision Cuts, Increase Productivity, And Ensure The Longevity Of The Machinery. Course Curriculum Overview A Comprehensive Lathe Training Course Will Cover The Following Topics: 1. **Safety Guidelines**: Understanding Safety Measures Essential For Operating A Lathe. 2. **Introduction To Lathe Components**: Familiarization With The Lathe’S Parts, Including The Carriage. 3. **Metal Lathe Carriage Operation**: Detailed Instructions On How To Manipulate The Carriage For Various Tasks. 4. **Setting Tool Height And Position**: Techniques To Set The Cutting Tool Correctly Using The Carriage. 5. **Practical Exercises**: Hands-On Practice For Real-World Application And Skill Development. Benefits Of Enrolling In A Lathe Training Course 1. **Skill Development**: Tailored Training Helps In Polishing Skills And Learning New Techniques. 2. **Increased Precision**: A Strong Understanding Of The Metal Lathe Carriage Results In Improved Accuracy. 3. **Career Opportunities**: Proficiency In Using Lathes Can Open Doors To Various Job Roles In Manufacturing And Engineering. Conclusion Enrolling In A Lathe Training Course Is An Invaluable Step For Anyone Eager To Master Machining Skills, Especially When It Comes To Operating A Metal Lathe And Effectively Using The Metal Lathe Carriage. With The Right Training, One Can Ensure Enhanced Productivity, Safety, And Quality In Machining Processes. Whether You Are A Beginner Or Looking To Refine Your Skills, A Structured Lathe Training Course Is A Worthwhile Investment In Your Professional Development.

Key Insights from a Lathe Training Course on Metal Lathe Carriage

Lathe training courses focus on essential skills for using a metal lathe carriage effectively. Participants learn about safety practices and common operations like turning and threading. Ever wondered how machine parts are crafted? These courses reveal the secrets behind precision and craftsmanship. Hands-on exercises help students gain confidence and improve their skills. With expert guidance, students can master techniques that turn raw metal into impressive shapes, unlocking new creative possibilities.Understanding Metal Lathes

Definition and function of metal lathes. Importance of metal lathes in manufacturing.Think of a metal lathe as a magic wand for shaping metal! It spins metal pieces while tools carve them into amazing shapes. These machines are like the superheroes of manufacturing. They create parts for cars, machines, and even spaceship models! Without metal lathes, we’d have a lot less cool stuff. Imagine a world without bicycles or toy robots! According to the National Association of Manufacturers, 75% of all manufactured items use metal parts. That’s a lot of turning!

| Function | Importance |

|---|---|

| Cuts and shapes metal | Essential for production |

| Enables precision work | Improves quality |

| Supports creativity | Drives innovation |

Benefits of Lathe Training Courses

Skill development and proficiency in metalworking. Career advancement opportunities for trained lathe operators.Learning to use a lathe can really boost your skills in metalworking. With a lathe training course, you will learn how to create shapes and parts precisely. This hands-on experience makes you more confident and skilled.

Moreover, trained lathe operators often have better job opportunities. Companies look for workers who know how to use tools correctly. So, completing a lathe training course can open doors to exciting careers.

- Improved metalworking skills

- Increased job opportunities

- Higher earning potential

Why take a lathe training course?

A lathe training course helps you gain important skills and can lead to better job options.

What to Expect in a Lathe Training Course

Course curriculum and key topics covered. Handson training and reallife applications.In a lathe training course, expect to dive into hands-on training. You’ll learn how to operate a metal lathe and work with the carriage, which is the part that moves tool holders. The course includes fun projects, like making your own pizza cutter. It’s not just theory; you’ll see real-life applications where these skills shine.

| Course Topics | Description |

|---|---|

| Lathe Operation | Basics of machine parts and functions. |

| Tool Selection | How to choose the right tool for the job. |

| Safety Practices | Essential tips to stay safe while you work. |

| Real-World Skills | Hands-on practice with fun projects. |

So grab your goggles and get ready to spin some metal! You’ll leave with skills that could even impress your grandparents.

Choosing the Right Lathe Training Program

Factors to consider when selecting a training course. Accreditation and recognition of training institutions.Choosing a lathe training program can be like picking ice cream flavors—there are so many! First, look at the factors that matter: course content, duration, and hands-on practice. Next, check if the school is accredited. This means others think it’s good too. A recognized program can help you stand out like a giraffe in a yard full of short fences! Use the table below to compare options easily:

| Factor | Importance |

|---|---|

| Hands-On Practice | Very Important |

| Accreditation | Essential |

| Course Length | Moderately Important |

Common Challenges in Lathe Training

Technical difficulties faced by learners. Solutions and resources for overcoming challenges.Learning to use a lathe can be tricky. Many students struggle with the machine’s controls and setup. They may also face problems with safety measures and precision. However, there are ways to make learning easier.

- Ask questions during class to clarify doubts.

- Practice regularly to build confidence and skill.

- Use online resources or videos for extra help.

- Join study groups to share tips with classmates.

Using these tips can turn challenges into opportunities for growth. With support and practice, anyone can master lathe skills!

What are common struggles in lathe training?

Beginners may find the controls confusing and struggle with safety. It’s normal to feel overwhelmed, but practice helps!

What can students do to improve their skills?

- Ask teachers for help.

- Watch instructional videos.

- Work with friends on projects.

Safety Practices During Lathe Training

Importance of safety protocols in metalworking. Essential safety equipment and practices.Metalworking can be exciting, but safety always comes first! Following safety protocols keeps everyone safe and sound. Wearing protective gear is a must—think goggles, gloves, and earplugs. Don’t forget to keep your workspace clean. It’s like making a sandwich; you need the right ingredients! Also, always pay attention while using the lathe; it’s no time for a catnap!

| Essential Safety Equipment | Importance |

|---|---|

| Safety Goggles | Protects eyes from flying debris |

| Gloves | Safeguards hands from sharp tools |

| Earplugs | Reduces noise levels for hearing safety |

In fact, did you know that most accidents in workshops happen due to negligence? So, always stick to your training guidelines. Remember, being safe is way cooler than an injury!

Success Stories from Lathe Training Graduates

Testimonials and experiences from past trainees. How training has transformed careers in metalworking.Many graduates of lathe training courses have shared their inspiring stories. These experiences show how the training changed their lives. For example:

- A student named Mike became a skilled machinist and now runs his own shop.

- Another trainee, Sara, found a job in a large manufacturing company.

- Tom used his skills to create custom parts for local businesses.

Thanks to the training, many have moved from basic jobs to successful careers in metalworking. Their new skills opened many doors and helped them achieve their dreams.

How has training benefited trainees?

Training has boosted careers, resulting in higher pay and job satisfaction. Graduates often feel more confident and skilled. The stories of past trainees show that hard work really pays off.

Conclusion

In summary, taking a lathe training course helps you master the metal lathe carriage. You’ll learn how to operate it safely and efficiently. Understanding this tool increases your skills and opens more opportunities in metalworking. Consider signing up for a course or reading more about metal lathes. Your journey to becoming a skilled machinist starts now!FAQs

Sure! Here Are Five Questions Related To A Lathe Training Course Focusing On The Metal Lathe Carriage:Sure! Here are five questions about the metal lathe carriage: 1. What does the carriage do? The carriage helps move the metal back and forth as we work on it. 2. How do we adjust the carriage? We can use handles and knobs to slide the carriage to the right or left. 3. Why is it important to keep the carriage clean? Keeping it clean helps the lathe work better and last longer. 4. What safety gear should we wear? You should wear safety goggles and gloves to protect yourself while working. 5. Can we practice using the carriage? Yes, we can practice moving the carriage on a safe machine to learn.

Sure, just let me know what question you want me to answer!

What Are The Key Components Of A Metal Lathe Carriage, And How Do They Function Together To Facilitate Machining Processes?A metal lathe carriage has a few main parts that help it work. First, there’s the bed that supports everything. Then, we have the saddle, which moves along the bed. The cross-slide sits on the saddle and can move side to side. Finally, the tool holder holds the cutting tool in place. Together, these parts let us shape metal by moving the tool while the metal spins.

In A Lathe Training Course, What Safety Protocols Should Be Emphasized When Operating The Carriage During Machining?When using the carriage on a lathe, always wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid injury. Make sure to check that the tools are secure before starting. Always keep the work area clean and organized. If you feel unsafe, stop and ask for help.

How Can Students Effectively Adjust And Calibrate The Lathe Carriage To Achieve Precise Measurements And Finishes On Workpieces?To adjust the lathe carriage, first, make sure it is clean and free of dirt. Next, loosen the adjusting screws gently. Slide the carriage to check if it moves smoothly. You can then tighten the screws to keep it steady. Finally, measure your workpiece again to ensure it’s just right!

What Common Issues Might Arise During The Operation Of A Metal Lathe Carriage, And How Can They Be Troubleshooting During Training?When using a metal lathe carriage, you might face some common problems. The carriage might move too slowly or get stuck. To fix these issues, we can check for dirt and make sure everything is clean. We can also look for loose parts and tighten them. During training, we should practice spotting these problems and fixing them quickly.

How Does The Design And Operation Of The Metal Lathe Carriage Differ Between Various Lathe Models, And What Implications Does This Have For Training?Different metal lathes have different carriages, which move the cutting tool. Some carriages are simple, while others have extra features. This means you need to learn how to use each type. When training, we must focus on the specific lathe model. Understanding the machine helps you work better and stay safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To A Lathe Training Course Focusing On The Metal Lathe Carriage:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about the metal lathe carriage: 1. What does the carriage do? The carriage helps move the metal back and forth as we work on it. 2. How do we adjust the carriage? We can use handles and knobs to slide the carriage to the right or left. 3. Why is it important to keep the carriage clean? Keeping it clean helps the lathe work better and last longer. 4. What safety gear should we wear? You should wear safety goggles and gloves to protect yourself while working. 5. Can we practice using the carriage? Yes, we can practice moving the carriage on a safe machine to learn.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, just let me know what question you want me to answer!”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Carriage, And How Do They Function Together To Facilitate Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe carriage has a few main parts that help it work. First, there’s the bed that supports everything. Then, we have the saddle, which moves along the bed. The cross-slide sits on the saddle and can move side to side. Finally, the tool holder holds the cutting tool in place. Together, these parts let us shape metal by moving the tool while the metal spins.”}},{“@type”: “Question”,”name”: “In A Lathe Training Course, What Safety Protocols Should Be Emphasized When Operating The Carriage During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the carriage on a lathe, always wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid injury. Make sure to check that the tools are secure before starting. Always keep the work area clean and organized. If you feel unsafe, stop and ask for help.”}},{“@type”: “Question”,”name”: “How Can Students Effectively Adjust And Calibrate The Lathe Carriage To Achieve Precise Measurements And Finishes On Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the lathe carriage, first, make sure it is clean and free of dirt. Next, loosen the adjusting screws gently. Slide the carriage to check if it moves smoothly. You can then tighten the screws to keep it steady. Finally, measure your workpiece again to ensure it’s just right!”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise During The Operation Of A Metal Lathe Carriage, And How Can They Be Troubleshooting During Training?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe carriage, you might face some common problems. The carriage might move too slowly or get stuck. To fix these issues, we can check for dirt and make sure everything is clean. We can also look for loose parts and tighten them. During training, we should practice spotting these problems and fixing them quickly.”}},{“@type”: “Question”,”name”: “How Does The Design And Operation Of The Metal Lathe Carriage Differ Between Various Lathe Models, And What Implications Does This Have For Training?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different metal lathes have different carriages, which move the cutting tool. Some carriages are simple, while others have extra features. This means you need to learn how to use each type. When training, we must focus on the specific lathe model. Understanding the machine helps you work better and stay safe.”}}]}