Have you ever wondered how metal objects are shaped and formed? It’s all thanks to machines like the lathe. A lathe is a powerful tool that spins metal to create amazing designs. But to use a lathe safely and effectively, you need proper training.

This is where a lathe training course comes in. It helps you understand how to operate the machine and control its movements. You learn about the control panel too, which is where you set all the important functions. What if I told you that mastering this simple control panel can open doors to exciting projects?

In this article, we will explore how taking a lathe training course can help anyone, even beginners. You will discover essential tips and tricks that will make your metalworking journey enjoyable. Are you ready to dive into the world of lathes?

Lathe Training Course: Master Metal Lathe Control Panel操作

Lathe Training Course: Metal Lathe Control Panel

A lathe training course focuses on essential skills for handling a metal lathe. You’ll learn to operate the control panel efficiently and understand its functions. Imagine creating precise shapes from solid metal—exciting, right? Mastering the control panel can lead to better measurements and smoother finishes. You’ll also discover safety tips and techniques to avoid common mistakes. With hands-on learning, you’ll gain confidence and a new hobby or career path!Importance of Lathe Training Courses

Benefits of enrolling in a lathe training course for beginners and advanced users. Industry demand and career opportunities for trained lathe operators.Taking a lathe training course opens many doors. It’s not just a class; it’s a golden ticket to understanding the magic of metal lathes! Beginners will learn the basics, while advanced users can sharpen their skills. Why is this important? Because trained operators are in high demand! The industry needs skilled workers more than ever. Plus, having this training can lead to exciting job opportunities and potentially better pay. As they say, “The best way to predict your future is to create it!”

| Benefits of Lathe Training Courses | Career Opportunities |

|---|---|

| Hands-on experience | Manufacturing sector jobs |

| Expert guidance | Higher starting salaries |

| Safety training | Job stability |

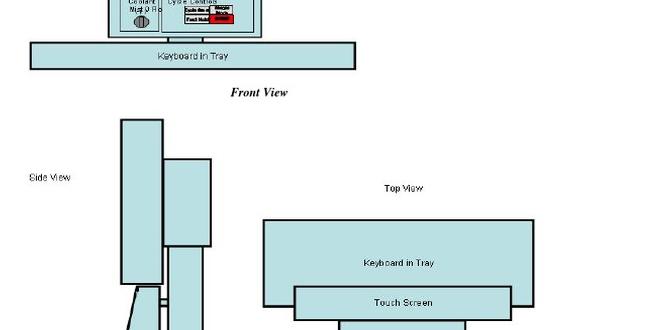

Key Components of a Metal Lathe Control Panel

Detailed explanation of control panel elements and their functions. Safety features incorporated in the control panel design.A metal lathe control panel has important parts that help with safe and easy operation. Key components include:

- Speed Control: This adjusts how fast the lathe spins.

- Feed Control: This changes how quickly the tool moves across the material.

- On/Off Switch: A clear button to start or stop the machine.

- Emergency Stop: This quickly stops everything in case of danger.

Safety features are vital. They help protect users from accidents. For example, the emergency stop is a must-have. Also, bright labels guide users. Always check safety locks before starting. This makes the workspace safer for everyone.

What are the main functions of control panel elements?

The main functions of control panel elements are to operate and monitor the lathe safely. They let users adjust speed and movement easily. Understanding these functions is crucial for effective training.

Course Curriculum: What to Expect

Breakdown of topics covered in a typical lathe training course. Handson training elements and practical projects included in the curriculum.In a lathe training course, expect to dive into various topics that boost your skills. You’ll learn about metal lathe parts, how to read blueprints, and set up the lathe. There’s plenty of hands-on training, too! You’ll create projects that make you the proud owner of shiny new metal pieces. It’s like art class, but with more metal shavings and less glitter!

| Topics Covered | Hands-on Training Elements |

|---|---|

| Lathe Components | Setup and Calibration |

| Blueprint Reading | Project Creation |

| Lathe Operation Techniques | Real-time Problem Solving |

This practical approach not only helps you learn, but also makes it fun. Get ready to spin, shape, and create like a pro! You’ll leave feeling confident and ready to tackle your own projects.

Choosing the Right Lathe Training Course

Factors to consider when selecting a lathe training program. Comparison of online vs. inperson training options.Picking the right lathe training course can change everything for you. Think about your learning goals first. Do you want to learn hands-on skills or prefer online lessons? Each option has benefits.

- Online Training: Study at your own pace and time.

- In-Person Training: Get direct help and feedback from teachers.

Look for a course with good reviews. Also, check if they offer a metal lathe control panel training. A great program can make learning fun and effective!

What should I look for in a lathe training course?

Focus on hands-on practice and instructor support! Real-life examples help you learn faster.

Essential Skills Gained Through Lathe Training

Key skills learned, including setup, operation, and troubleshooting. Importance of precision and accuracy in metal machining.Lathe training teaches important skills for working with metal. Students learn how to set up machines and operate them safely. Troubleshooting is also a key part of the course, helping students solve problems quickly. Precision and accuracy are vital in metal machining. Even the smallest mistake can change the outcome. Mastering these skills leads to high-quality work. Here are some key skills learned:

- Machine Setup

- Safe Operation

- Troubleshooting Techniques

- Focus on Precision

- Ensuring Accuracy

Why is precision important in metal machining?

Precision ensures parts fit together correctly and function properly. Without it, machines can break and cause accidents. Proper training helps students understand this crucial aspect.

Real-world Applications of Skills Learned in Lathe Training

Examples of industries that benefit from trained lathe operators. Case studies of successful projects completed by trainees.Many industries benefit from the skills gained in a lathe training course. For instance, the automotive sector relies heavily on trained lathe operators to shape engine components with precision. The aerospace industry also needs skilled operators to create parts that help planes fly safely. In fact, trainees have successfully completed projects that saved companies time and money!

| Industry | Example Project | Outcome |

|---|---|---|

| Automotive | Engine Parts | Increased efficiency |

| Aerospace | Safety Components | Improved safety |

These exciting adventures in learning show that when trainees grasp lathe skills, they can turn ideas into real-life solutions. Who knew making metal pieces could be so cool?

Frequently Asked Questions About Lathe Training

Common inquiries and concerns regarding the course structure and outcomes. Clarification on certifications and qualifications gained through training.Many people ask about lathe training programs. Questions often focus on the course structure and what you will learn. Students want to know how to control the metal lathe confidently. Others ask about the certifications they will earn after completing the course. Good news! Graduates leave with skills and knowledge that employers value. Certifications can boost job prospects. Remember, learning is like baking: a pinch of fun makes it rise!

| Common Questions | Answers |

|---|---|

| What will I learn? | You’ll master metal lathe operation. |

| Is there a certificate? | Yes! You’ll receive a certification. |

| Can I find a job after? | Definitely! Skills are in demand. |

Conclusion

In conclusion, a lathe training course teaches you how to use a metal lathe effectively. You learn about the control panel and its functions. Understanding this equipment is essential for machining tasks. Consider signing up for a course to gain hands-on experience. By doing this, you’ll improve your skills and confidence in metalworking. Explore more resources to keep learning!FAQs

What Are The Essential Components Of A Metal Lathe Control Panel That Trainees Should Be Familiar With During The Lathe Training Course?In a metal lathe control panel, you need to know a few important parts. First, there is the power switch. This turns the machine on and off. Next, there are buttons for controlling speed and direction. These help you make changes to how the lathe works. Finally, you should understand the emergency stop button, which stops the machine quickly if something goes wrong. Knowing these parts helps you use the lathe safely and effectively.

How Does The Control Panel Interface Enable Users To Adjust The Speed And Feed Rate Of The Metal Lathe?The control panel on a metal lathe helps you change how fast it spins and how quickly it moves. You can use buttons or knobs to set the speed. If you want it to go faster or slower, just turn the knob or press the right button. This way, you can make your work easier and get better results!

What Safety Features Are Incorporated Into The Lathe Control Panel, And How Should Trainees Respond To Potential Hazards While Operating The Machine?The lathe control panel has important safety features to keep you safe. There may be emergency stop buttons that quickly turn off the machine. There can also be guards that protect you from moving parts. If you see any problem, like loud noises or smoke, stop right away and tell an adult. Always remember, safety first!

Can You Explain The Role Of Digital Readouts (Dro) In The Lathe Control Panel And How They Assist In Precision Machining?Digital readouts, or DROs, help you see measurements on a lathe. They show how far the tool moves and how deep it cuts. This makes it easier for you to be accurate when shaping materials. With DROs, you can check your work quickly and make sure everything is just right. They help us create better and more precise parts!

What Troubleshooting Techniques Should Trainees Learn For Diagnosing And Resolving Common Issues Related To The Metal Lathe Control Panel?You should start by checking if the control panel is turned on. Look for any flashing lights or warning messages. If something seems wrong, unplug the machine and examine the wires for damage. You can also ask a teacher or a teammate for help if you’re stuck. Finally, practice solving these issues so you get better at it!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe Control Panel That Trainees Should Be Familiar With During The Lathe Training Course? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe control panel, you need to know a few important parts. First, there is the power switch. This turns the machine on and off. Next, there are buttons for controlling speed and direction. These help you make changes to how the lathe works. Finally, you should understand the emergency stop button, which stops the machine quickly if something goes wrong. Knowing these parts helps you use the lathe safely and effectively.”}},{“@type”: “Question”,”name”: “How Does The Control Panel Interface Enable Users To Adjust The Speed And Feed Rate Of The Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The control panel on a metal lathe helps you change how fast it spins and how quickly it moves. You can use buttons or knobs to set the speed. If you want it to go faster or slower, just turn the knob or press the right button. This way, you can make your work easier and get better results!”}},{“@type”: “Question”,”name”: “What Safety Features Are Incorporated Into The Lathe Control Panel, And How Should Trainees Respond To Potential Hazards While Operating The Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe control panel has important safety features to keep you safe. There may be emergency stop buttons that quickly turn off the machine. There can also be guards that protect you from moving parts. If you see any problem, like loud noises or smoke, stop right away and tell an adult. Always remember, safety first!”}},{“@type”: “Question”,”name”: “Can You Explain The Role Of Digital Readouts (Dro) In The Lathe Control Panel And How They Assist In Precision Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Digital readouts, or DROs, help you see measurements on a lathe. They show how far the tool moves and how deep it cuts. This makes it easier for you to be accurate when shaping materials. With DROs, you can check your work quickly and make sure everything is just right. They help us create better and more precise parts!”}},{“@type”: “Question”,”name”: “What Troubleshooting Techniques Should Trainees Learn For Diagnosing And Resolving Common Issues Related To The Metal Lathe Control Panel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should start by checking if the control panel is turned on. Look for any flashing lights or warning messages. If something seems wrong, unplug the machine and examine the wires for damage. You can also ask a teacher or a teammate for help if you’re stuck. Finally, practice solving these issues so you get better at it!”}}]}